Method for producing styrene by catalytic dehydrogenation

A technology for catalytic dehydrogenation of ethylbenzene and styrene, applied in chemical instruments and methods, organic chemistry, hydrocarbons, etc. efficiency and other issues to achieve the effect of high selectivity and improved conversion of ethylbenzene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

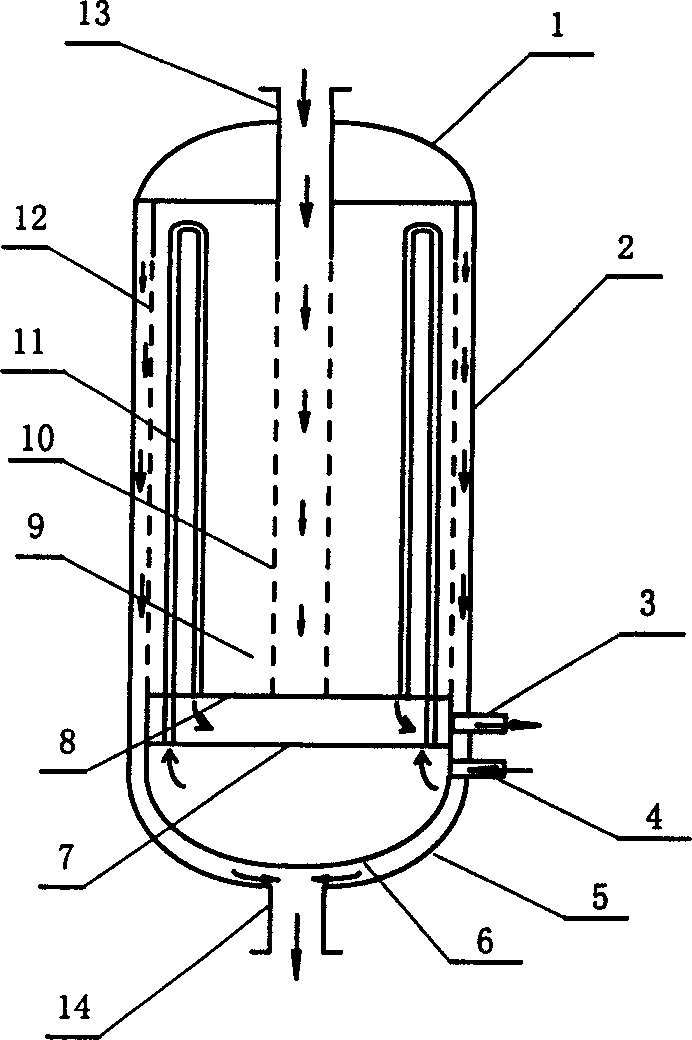

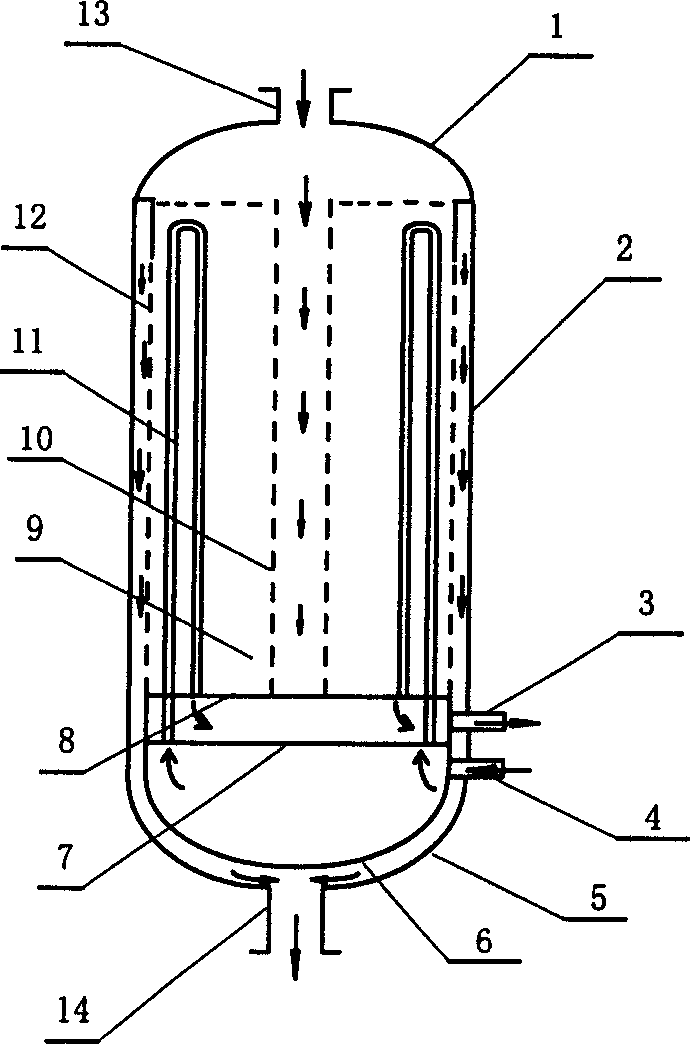

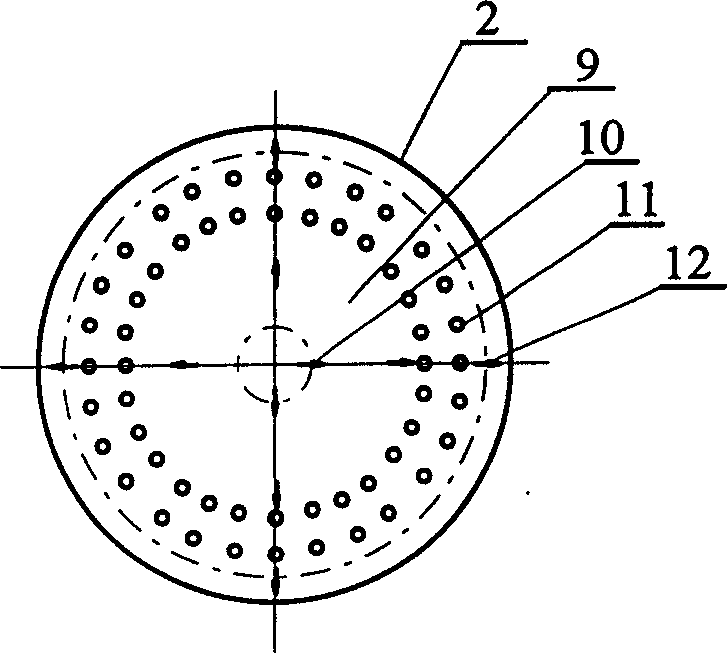

Embodiment 1

[0040] The catalytic dehydrogenation of ethylbenzene / steam mixture is carried out with a set of equipment, and its production block diagram is shown as Figure 4 . Both the first reactor and the second reactor use figure 1 or figure 2 In the reactor, the catalyst used is iron-potassium-cerium-molybdenum system. The diameter of the distribution cylinder in the reactor is 1150 mm, the radial thickness of the bed is 600 mm, and the total static height is 5500 mm. The reactor is in the form of an axial radial reactor with many small holes on the upper cover. The heating tube is an inverted U-shaped tube that penetrates into the entire catalyst bed. The number of heating tubes in each reactor is 100, which are evenly distributed in the radial direction. On the section, the heat carrier passes through the inverted U-shaped tube. The temperature of the reaction material entering the first reactor is 620°C, the pressure is 58KPa, the total flow rate is 32257.2 kg / hour, the temper...

Embodiment 2

[0044] According to the conditions and steps of Example 1, only the type of heating tube is changed to double casing, the number of double casing is 500, the outlet temperature of the first reactor is uniform at 550.9°C, and the reaction result is: the conversion rate of ethylbenzene is 48.11%. , the styrene selectivity was 96.0%, and the styrene yield was 46.2%. The outlet temperature of the second reactor was uniform at 585.5° C., and the conversion rate of ethylbenzene was 49.8%.

Embodiment 3

[0046] According to the conditions and steps of Example 1, just change the type of heating tubes to 300 inverted U-shaped tubes and double sleeve tubes, the outlet temperature of the first reactor is nearly uniform at 545.3°C, and the reaction result is: the conversion rate of ethylbenzene is 44.15%. , the styrene selectivity was 97.2%, and the styrene yield was 42.9%. The outlet temperature of the second reactor was nearly uniform at 581.3°C, and the conversion rate of ethylbenzene was 47.5%.

[0047] components

[0048] components

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com