A kind of micro-nano fiber reinforced concrete and preparation method thereof

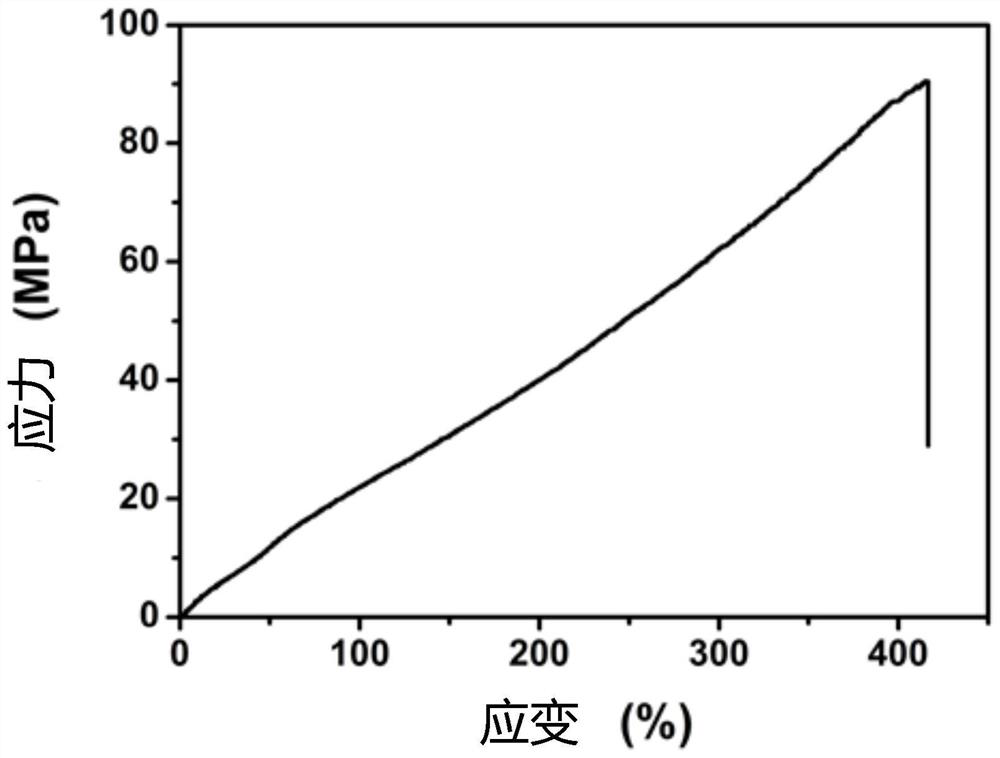

A fiber reinforced concrete technology, applied in the field of building materials, can solve the problems of affecting the mechanical properties of concrete, fiber agglomeration, affecting the bonding force between fibers and substrates, etc., to enhance mechanical properties and durability, improve pore structure, and dense microstructure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

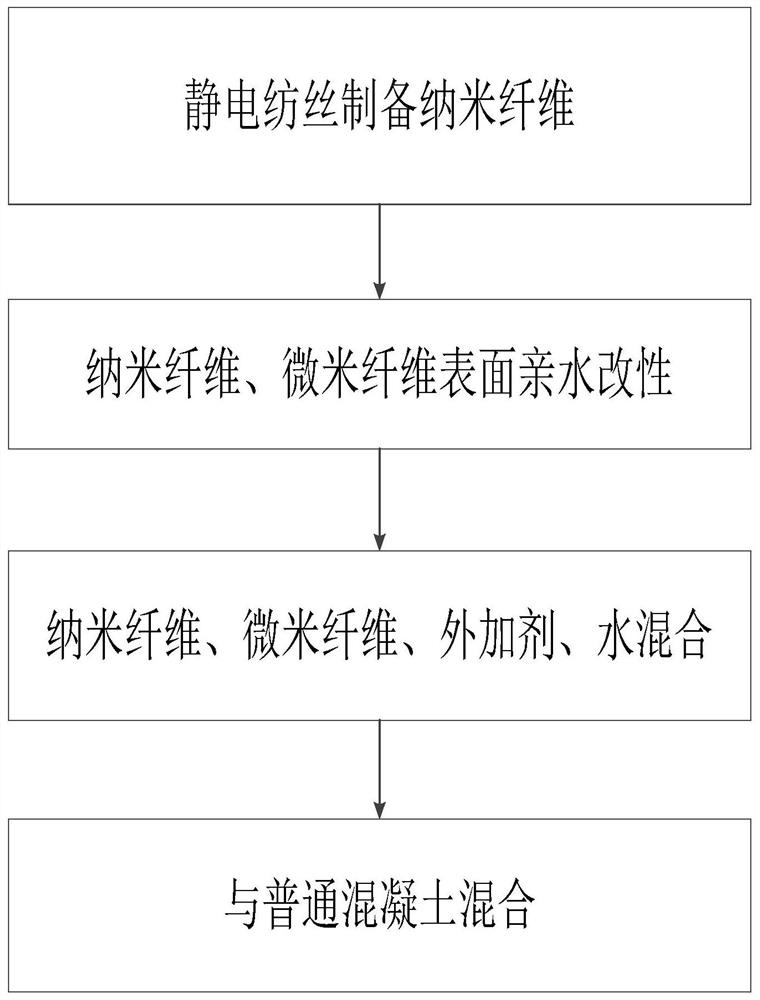

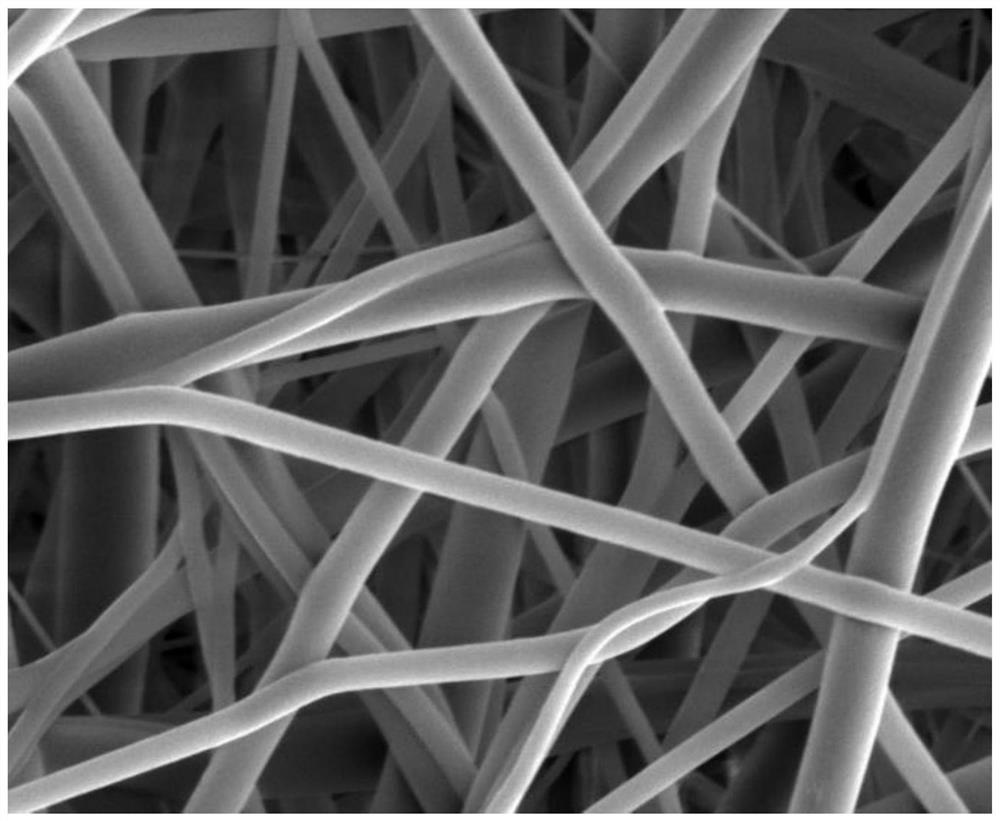

[0043] The preparation method of concrete reinforced with micro-nano fibers includes the process of preparing nanofibers by electrospinning; specifically, the electrospinning process includes: adding a polymer to a solvent and magnetic stirring to obtain an electrospinning solution; electrospinning The silk solution is added to the nozzle for electrospinning to obtain nanofibers; as an optional embodiment, the concentration of the electrospinning solution is set to 10-30%, and the time of magnetic stirring is set to not less than 6 hours; the voltage of the electrospinning Set it to 10-30kV, set the propulsion speed of the spinning solution to 0.3-5mL / h, set the receiving distance from the spinneret to the drum at 15-30cm, set the spinning environment temperature to 20-45°C, and set the relative humidity of the surrounding environment to 30-80%.

[0044] The preparation method of concrete reinforced by micro-nano fibers includes the process of modifying the surface of nanofibe...

Embodiment 1

[0047] In Example 1, the micro-nano fiber-reinforced concrete includes thermoplastic polyurethane nanofibers, polyethylene-polypropylene blended microfibers, nano-silica, and also includes coarse aggregate, fine aggregate, water, and cement. The preparation process is as follows:

[0048] The preparation of thermoplastic polyurethane nanofibers by electrospinning technology specifically includes: adding high-molecular polymers into solvents, performing magnetic stirring, as an electrospinning solution; adding the prepared electrospinning solution into the nozzle, and performing electrospinning to obtain Nanofiber membrane; dry the nanofiber membrane to fully evaporate the solvent.

[0049] Hydrophilic modification of prepared thermoplastic polyurethane nanofibers and polyethylene-polypropylene blended microfibers by plasma surface treatment method; specifically includes: using low-temperature plasma to initiate acrylic acid surface grafting on the surface of electrostatic nanof...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com