Adsorbent based on a zeolite and a silica-rich clay, and process for purifying hydrocarbon feeds

An adsorbent, zeolite technology, applied in adsorption purification/separation, chemical instruments and methods, separation methods, etc., can solve the problems of complex and more expensive forming methods, reducing adsorption capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0094] This additive will be removed during the heat treatment of step (d) of the production process of the invention.

[0095] Said step (b) is advantageously carried out in a ram extruder, single screw extruder or twin screw extruder.

[0096] In this case, additives may optionally be added to the mixing step (a). The presence of said additives facilitates extrusion.

[0097] In the case where the production process is carried out continuously, the mixing step (a) can be combined with step (b) for shaping by extrusion in the same equipment. In this embodiment, the mixture is extruded, also referred to as "mixed slurry", for example by extrusion directly from the end of a continuous twin-screw type mixer, or by mixing one or more machine connected to the extruder to execute. The geometry of the die that gives the extrudate its shape may be selected from dies known to those skilled in the art. Thus, the mold can be, for example, cylindrical, multi-lobed, channeled or groov...

Embodiment

[0139] NaX zeolite extrudates were synthesized as follows:

[0140] The zeolite and binder powders were introduced into the chamber of a mixer (Plastograph, Brabeender), deionized water was added by syringe over about 2 minutes and mixed. The mixture was then mixed for 20 minutes at 25 rpm.

[0141] The resulting slurry was then extruded through a cylindrical die with a diameter of 1.8 mm (ram extruder). Finally, the rods were dried overnight at 80°C and calcined at 550°C in air.

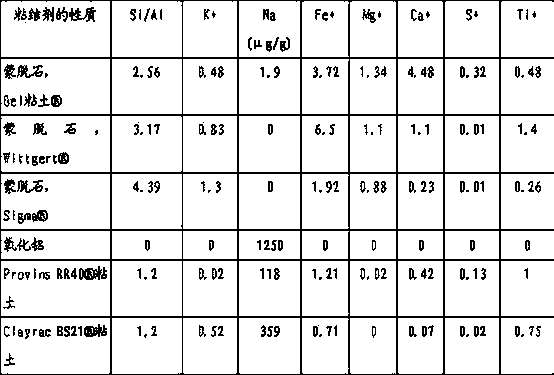

[0142] For comparison, Examples A to F have various clay or oxide type binders prepared using the same procedure (Table 2). The Si / Al weight ratios of the various binders and the amounts of their various impurities are shown in Table 1 below.

[0143]

[0144] Table 1: Properties of binder, Si / Al weight ratio, impurities

[0145]

[0146] * weight%

[0147] Then, the reactivity of the adsorbent was tested as follows. First, the adsorbent was activated at 400 °C for 2 h in nitrogen. Then, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com