Electromagnetic magnetron sputtering method applied to photovoltaic transparent conductive glass

A technology of transparent conductive glass and magnetron sputtering, applied in the field of electromagnetic magnetron sputtering, which can solve the problems of fragility, lower glass substrate film deposition temperature, and short discharge distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

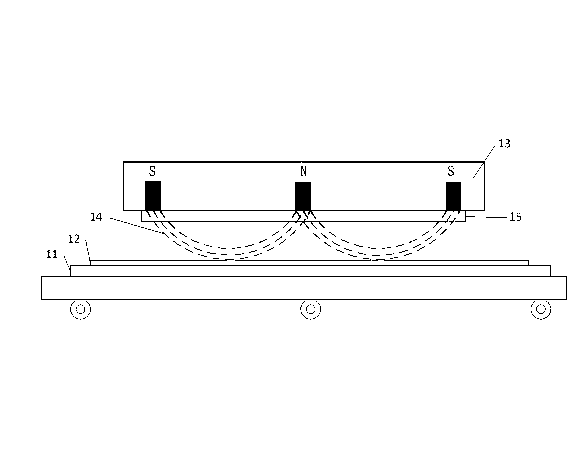

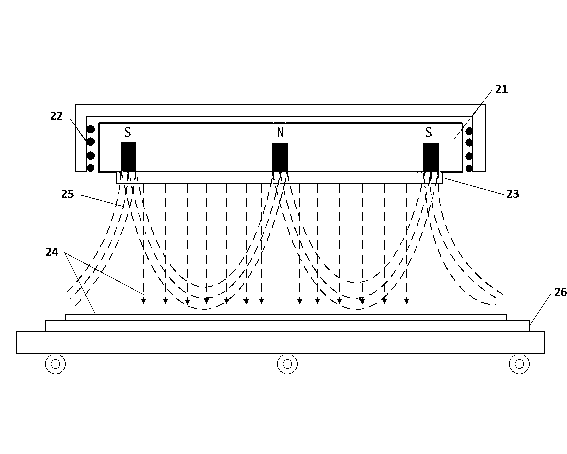

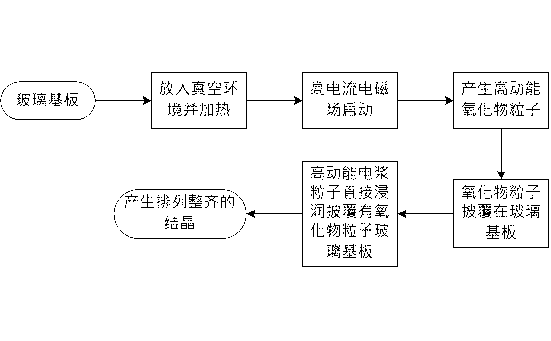

[0019] In order to make it easier to understand other features and advantages of the present invention and the effects achieved, the present invention will be described in detail as follows in conjunction with the accompanying drawings: Please refer to figure 2 , image 3 As shown, the main purpose of the present invention is to provide an electromagnetic magnetron sputtering method applied to solar transparent conductive glass, which is to put the glass substrate 26 into a vacuum environment and heat it. The heating temperature is 100 ° C ~ 150 ° C, The periphery of the target source 21 is provided with 4 sets of high-current electromagnetic fields 22 surrounding it. The 4 sets of high-current electromagnetic fields 22 are stacked on the sputtering target 23 to form an electromagnetic field 25 and generate a plasma discharge area, resulting in high kinetic energy. Oxide 24 particles, and the oxide 24 particles are deposited and coated on the glass substrate 26, the electroma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com