A multi-pipe air inlet mixed air chamber

A technology of mixing air silo and air intake, applied in the direction of pipeline layout, etc., can solve the problems of small air output, limited application range, large energy consumption, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

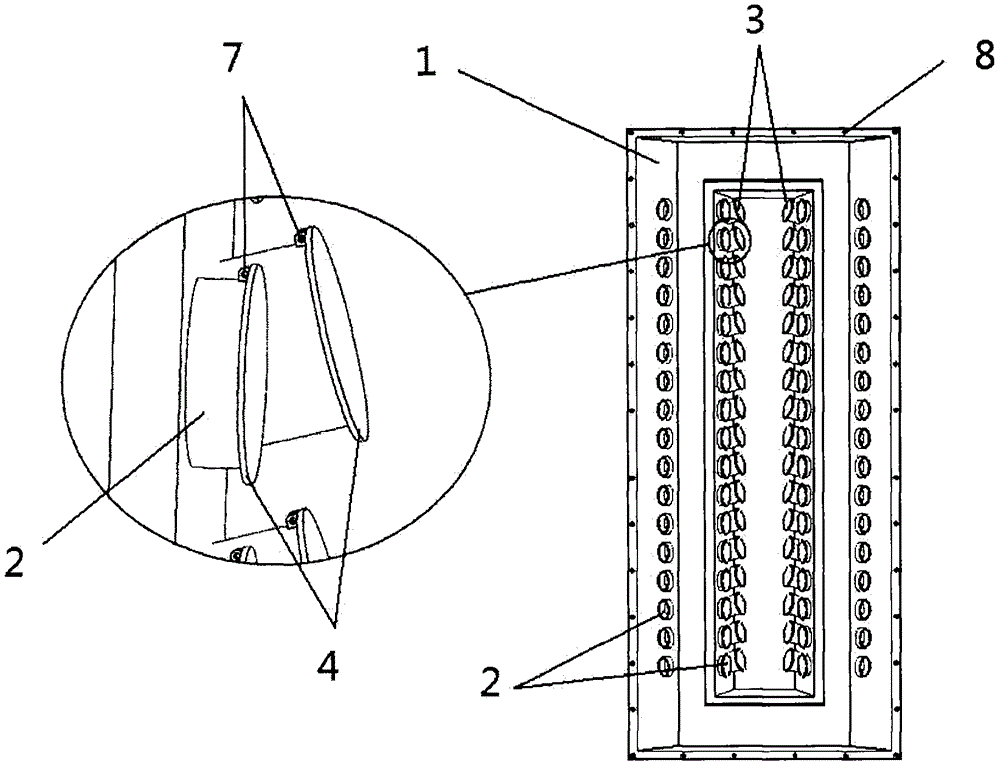

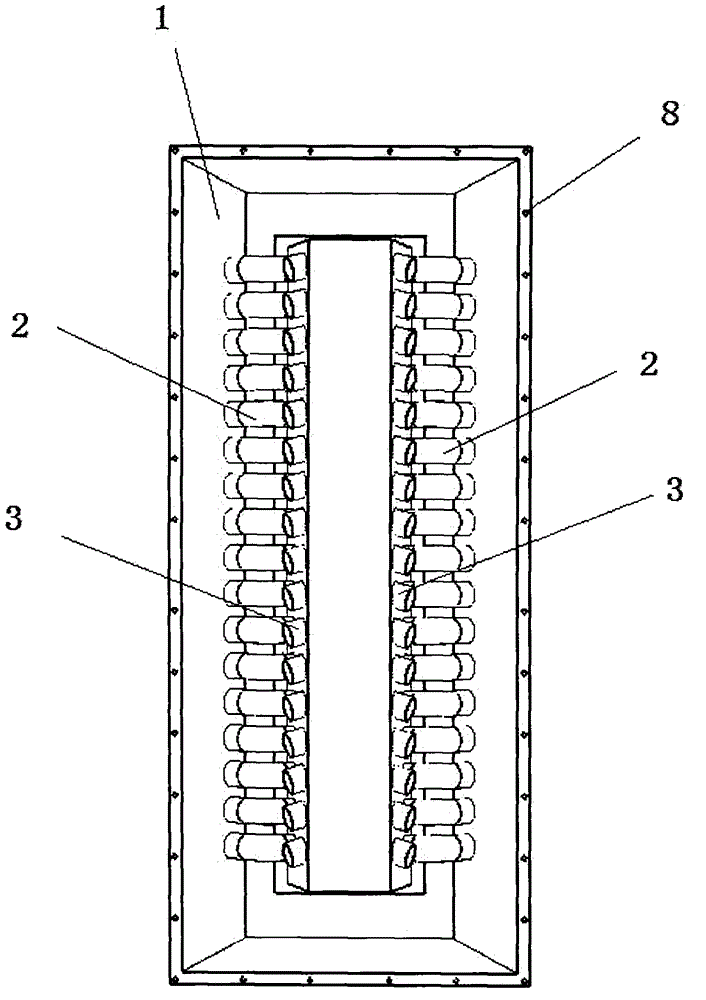

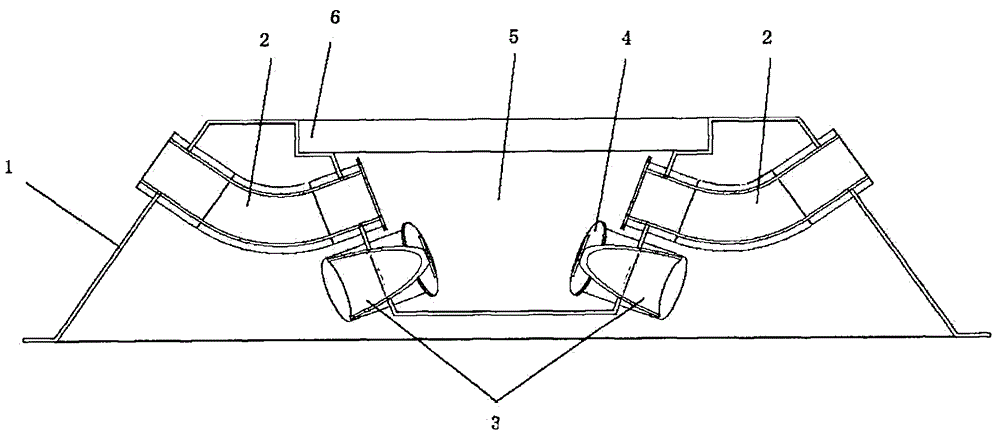

[0018] Figure 1 to Figure 4 Shown is the best embodiment of the present invention applied in the fresh air system of the containerized data center. As shown in the figure, a multi-pipe air inlet mixing chamber includes a housing 1, 2 groups of indoor air inlet pipes, 3 groups of outdoor air inlet pipes, and an anti-downdraft valve 4. The housing 1 is an irregular three-dimensional structure, which is composed of two trapezoidal connections inside and outside. The inner trapezoidal shape of the housing 1 forms the air mixing area 5, and the outer trapezoidal structure is to separate the indoor air inlet pipes from 2 groups and the outdoor air inlet pipes from 3 groups. The air intake area is designed for easy fixing. One side of the inner trapezoid of the casing 1 is an open mixed air outlet 6, which can meet the demand for a larger air supply volume.

[0019] The 2 groups of indoor air inlet pipes are composed of 34 indoor air inlet pipes 2, and the 3 groups of outdoor air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com