Water treatment system based on aeration control

A water treatment system and aeration technology, applied in the direction of water/sludge/sewage treatment, water aeration, sustainable biological treatment, etc., can solve the problem of dynamic adjustment of air bubbles, increase of oxygen content in wastewater, and inability to change the fluidization of fillers Speed and other issues, to avoid the effect of increasing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

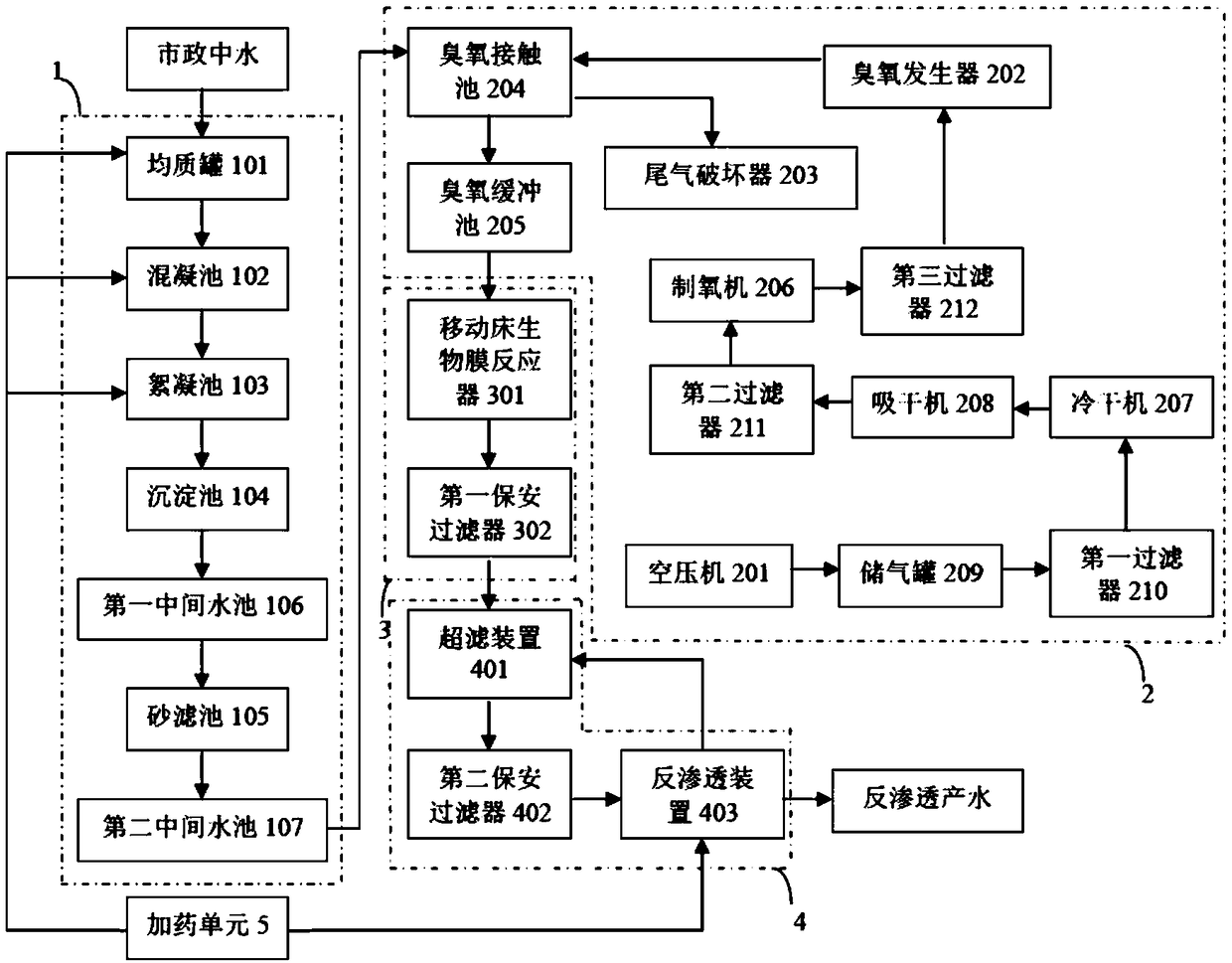

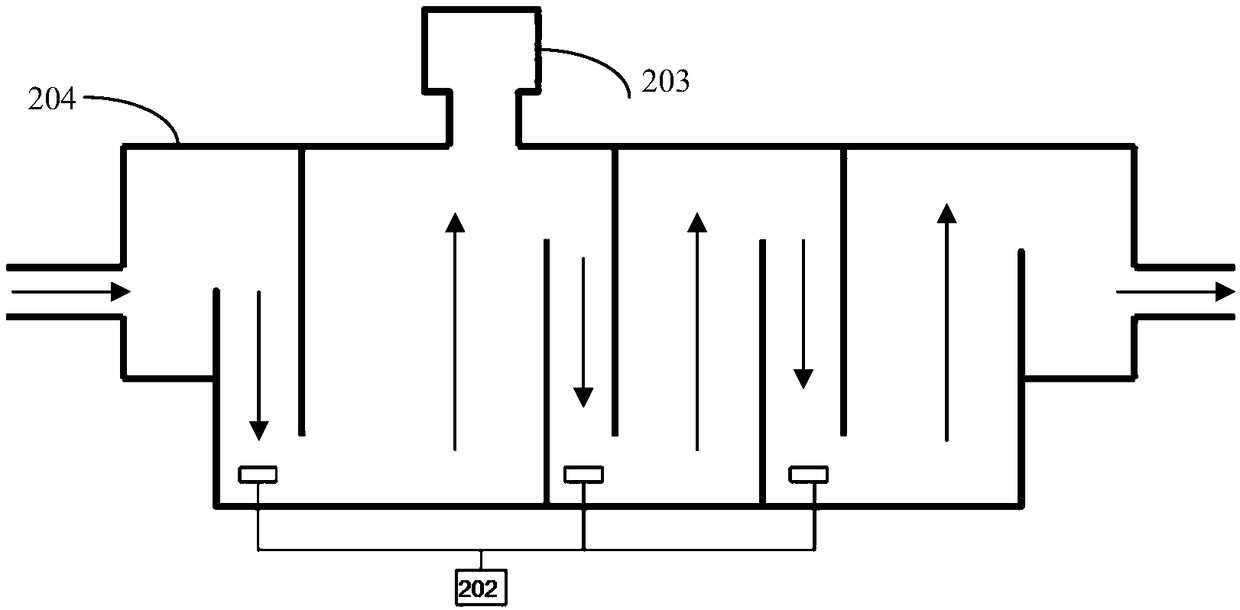

[0051] figure 1 Shows a schematic diagram of the water treatment process based on the water treatment system. Such as figure 1 As shown, the water treatment system at least includes a pretreatment unit 1, an oxidation unit 2, a biochemical treatment unit 3, a deep treatment unit 4, and a dosing unit 5. The pretreatment unit reduces the hardness, COD, colloid content and turbidity of the feed water through physical and chemical reactions to improve the efficiency and operational stability of the oxidation unit. The oxidation unit adopts the ozone oxidation process to further degrade COD and improve the biodegradability of the influent water on the basis of ensuring the color removal rate. The biochemical treatment unit adopts the aerated biological filter process and the moving bed biofilm reactor to further degrade COD and ensure the water inlet stability of the advanced treatment unit. The advanced treatment unit is used to remove the salt in the influent water based on the m...

Embodiment 2

[0062] This embodiment is a further improvement of Embodiment 1, and the repeated content will not be repeated.

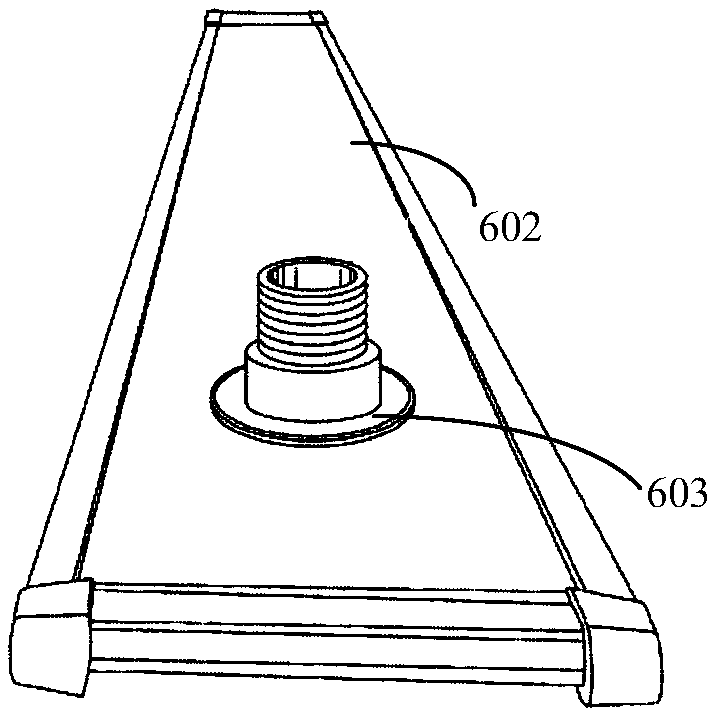

[0063] Such as image 3 with Figure 4 As shown, the present invention also provides an aerator used in the moving bed biofilm reactor. The aerator 6 is at least composed of an aeration membrane 601, a mounting plate 602 and an air inlet connector 603, wherein the shape of the mounting plate 603 is defined by a rectangular plate shape. At least one air inlet interface is provided on the first mounting surface of the mounting plate. The shape of the aeration diaphragm is defined by a circular arc-shaped curved surface with a certain arc, so that after the aeration diaphragm is fixed on the mounting plate, a gas cavity 604 can be formed between the two. Preferably, the shape of the aeration membrane may be defined by a semicircular arc. A through hole is provided at the position where the air inlet connector is fixed on the mounting plate so that the air inlet connect...

Embodiment 3

[0066] This embodiment is a further improvement of Embodiment 1 and Embodiment 2, and the repeated content will not be repeated.

[0067] The invention also provides an integrated use method of the aerator. Such as Figure 5 As shown, the moving bed biofilm reactor is configured as a working mode in which the anaerobic reaction zone and the aerobic reaction zone are arranged side by side. The wastewater after upstream treatment first enters the anaerobic reaction zone through its water inlet. The anaerobic reaction zone and the good The oxygen reaction zone is connected by pipelines so that the anaerobic treated wastewater can enter the aerobic reaction zone for the first time for reaction, and the wastewater treated by the aerobic reaction zone is discharged out of the moving bed biofilm reactor through the drain. Specifically, the moving bed biofilm reactor at least includes a reactor body 704 divided into an anaerobic reaction zone 702 and an aerobic reaction zone 703 by a par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com