Magnetism-gas mixed hybrid bearing and installation method thereof

A technology of dynamic and static pressure bearings and sliding bearings, applied in the field of bearings, can solve problems such as overheating, inapplicability, and inapplicability to large load conditions, and achieve the effects of reducing collision friction and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

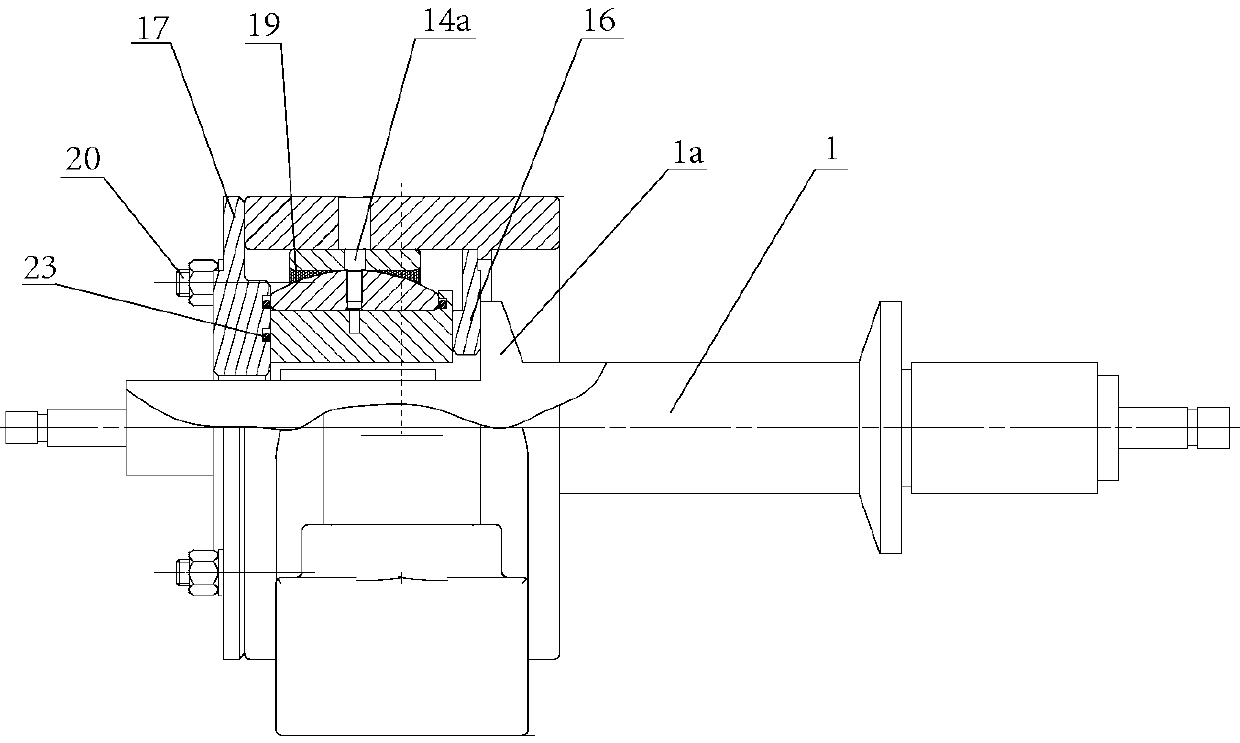

[0074] The outer magnetic poles in this embodiment are processed by cutting and then splicing.

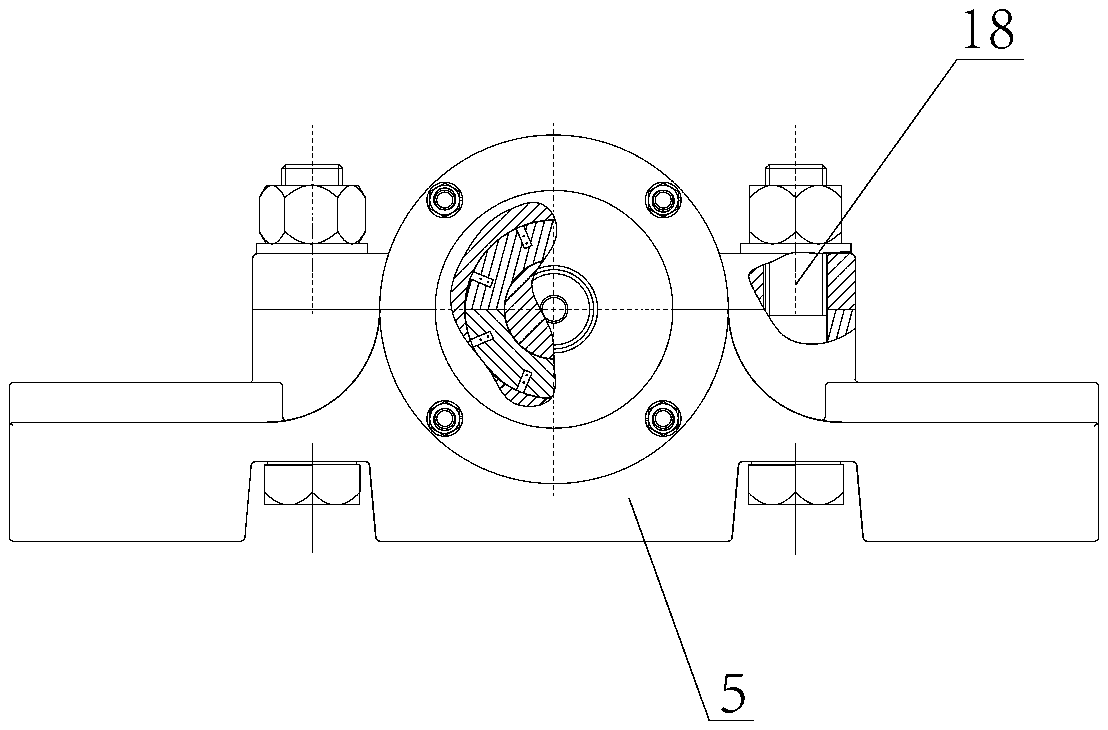

[0075] The outer ring is the outer magnetic pole, and the inner ring is the inner magnetic pole. For the convenience of observation, the d with C Exaggerated, the thickness of the outer magnetic pole actually cut off in this embodiment d=0.1mm . Among them, the center of the circle is O 1 The part of the semicircle located in the first and second quadrants is cut, and the center of the circle is O 2 The part of the semicircle located in the third and fourth quadrants is cut; the remaining parts of the two semicircles after cutting are butted and spliced together to form the olive-shaped structure required by the present invention. The inner peripheral surface of the olive-shaped outer magnetic pole includes a tip and a belly end. Compared with the inner peripheral surface of a perfectly circular outer magnetic pole, a larger wedge-shaped gap is formed between the inner mag...

Embodiment 2

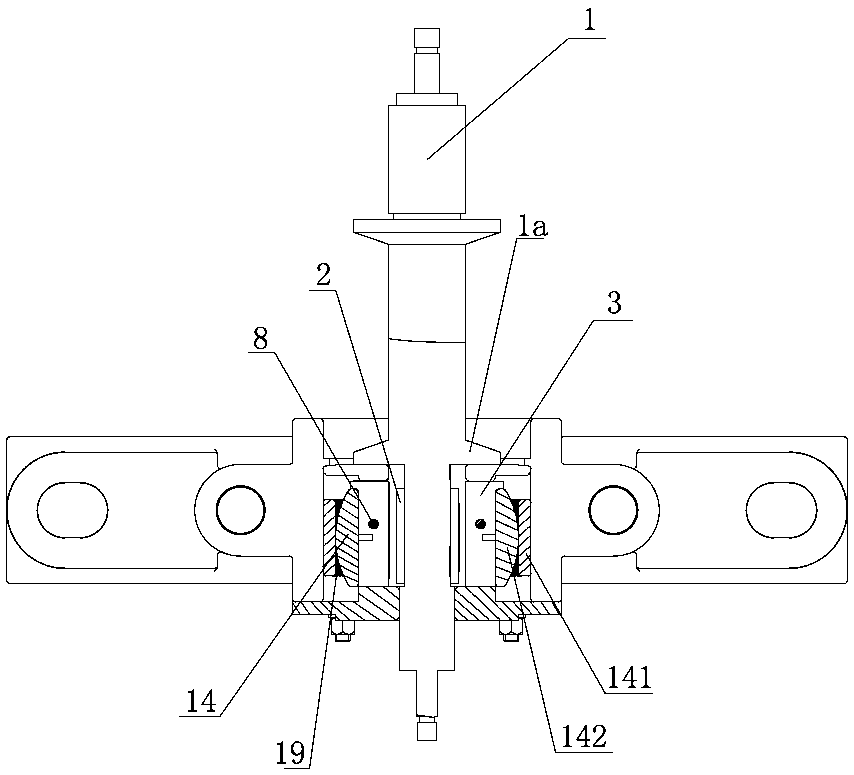

[0094] The structure of embodiment 2 is basically the same as that of embodiment 1, the difference is:

[0095] When the inner peripheral surface of the outer magnetic pole is provided with dynamic pressure generating grooves, the dynamic pressure generating grooves are arranged in a rectangular shape, and the dynamic pressure generating grooves are V-shaped grooves arranged continuously or at intervals. The dynamic pressure generating grooves in this embodiment are continuous V-shaped grooves. Groove. Adding dynamic pressure generating grooves on the inner peripheral surface of the outer magnetic poles can generate dynamic pressure on the one hand, thereby providing sufficient radial support for the rotating shaft; on the other hand, based on the hydrodynamic characteristics of the fine grooves, the The gap is filled with lubricating fluid so that it can be fully lubricated.

[0096] The installation method of the magnetic gas hybrid dynamic and static pressure bearing in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com