Drying device in high-speed rough drawing production line

A drying device and production line technology, applied in drying, drying machine, progressive dryer and other directions, can solve the problems of long drying box length and large area, and achieve short drying box length and occupying space. Small area, good drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Below in conjunction with accompanying drawing example, the present invention is described in further detail:

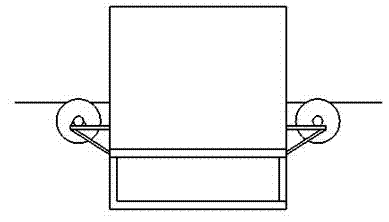

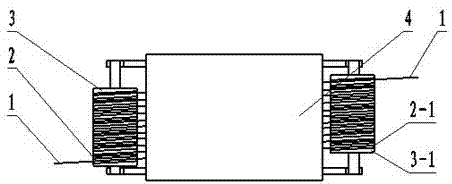

[0009] Such as figure 1 The shown embodiment includes wire rod 1, wire groove 2, wire groove 2-1, feeding drum 3, feeding drum 3-1, drying box 4.

[0010] exist figure 1 , figure 2 The feeding drums 3 and 3-1 shown in the figure are respectively provided with wire slots 2 distributed in a spiral shape. The spiral wire groove 2 of the material drum 3 and the spiral wire groove 2-1 of the feeding drum 3-1 at the discharge end pass back and forth through the drying box 4 and finally from the spiral wire groove of the feed drum 3-1 at the discharge end. The end of the wire duct 2-1 is output to the next process of the production line. Since the wire 1 passes through the drying box 4 multiple times back and forth, the residence time of the wire 1 in the drying box 4 is ensured, and the drying effect is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com