The sealing device of the lower part of the trolley of the blast ring cooler

A technology of sealing device and annular cooler, which is applied in the direction of processing discharged materials, furnaces, lighting and heating equipment, etc., can solve the problems of periodic thermal deformation of annular cooler, reduced air leakage rate, high air leakage rate, etc., to improve waste heat recovery efficiency, saving power consumption, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

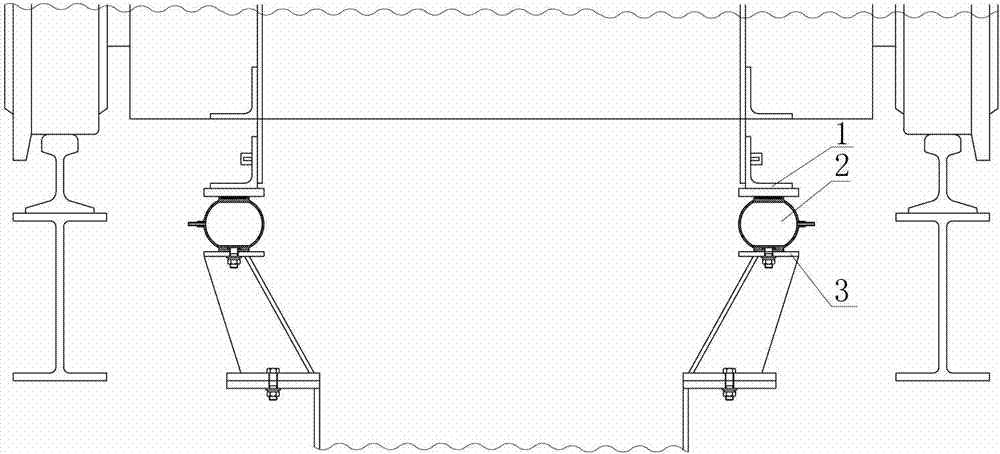

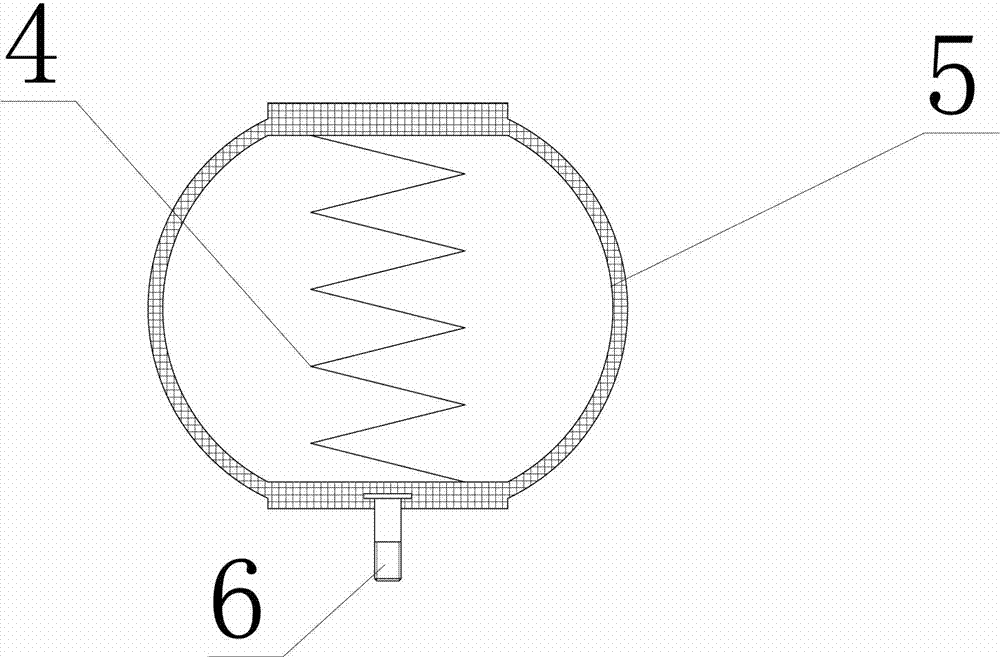

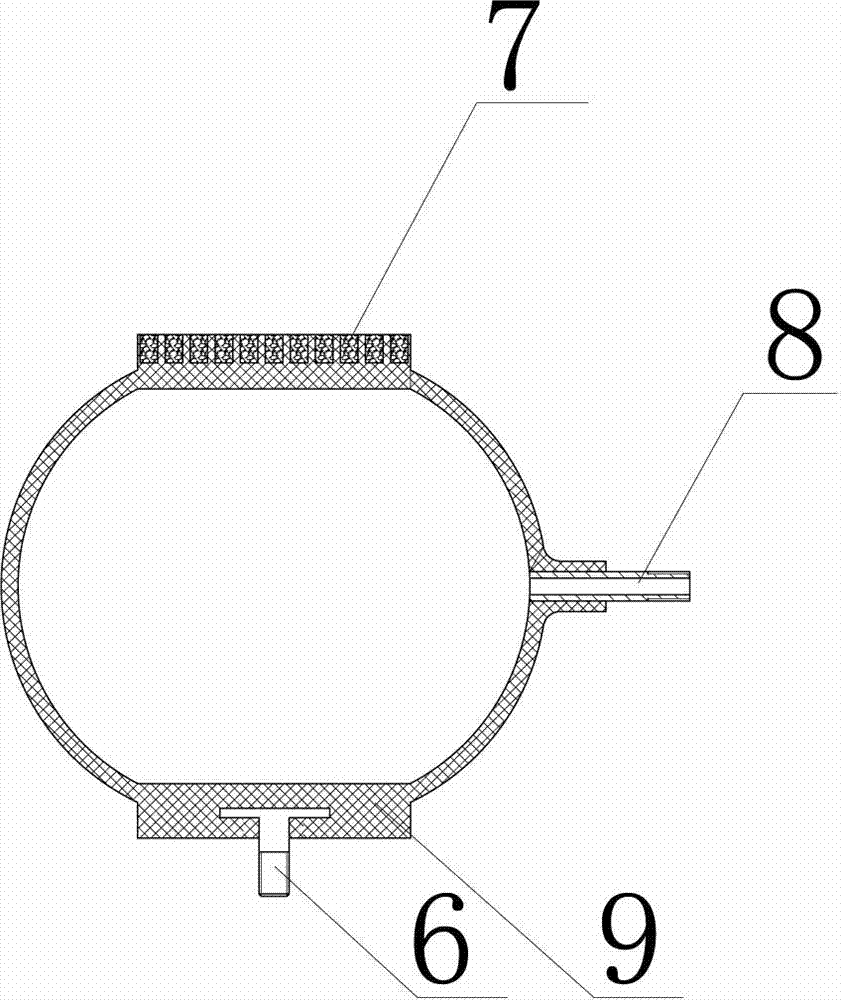

[0020] like figure 1 , 2 As shown in and 3, the lower sealing device of the trolley of the blast ring cooler of the present invention includes an upper movable sealing body 1 connected to the lower rail of the trolley, and a lower fixed sealing body 3 fixed on the grooved beam of the bellows. It is characterized in that an airtight bladder seal body 2 is provided between the upper movable seal body 1 and the lower fixed seal body 3, and the airtight bladder seal body 2 is slidably connected with the upper movable seal body 1, The airtight capsule sealing body 2 is fixedly connected with the lower fixed sealing body 3, and the structure of the airtight capsule sealing body 2 is a strip-shaped capsule structure with a closed cavity.

[0021] The airtight bag-type sealing body 2 is a metal braided airbag, and this metal braided airb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com