Box for preparing and forming laser material with controllable ambient temperature under inert atmosphere

A technology of inert atmosphere and laser materials, applied in the direction of laser welding equipment, welding equipment, manufacturing tools, etc., can solve the problems that cannot meet the requirements of rapid prototyping, achieve the effect of rich metallic luster, widen the variety, and reduce the intensity of thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

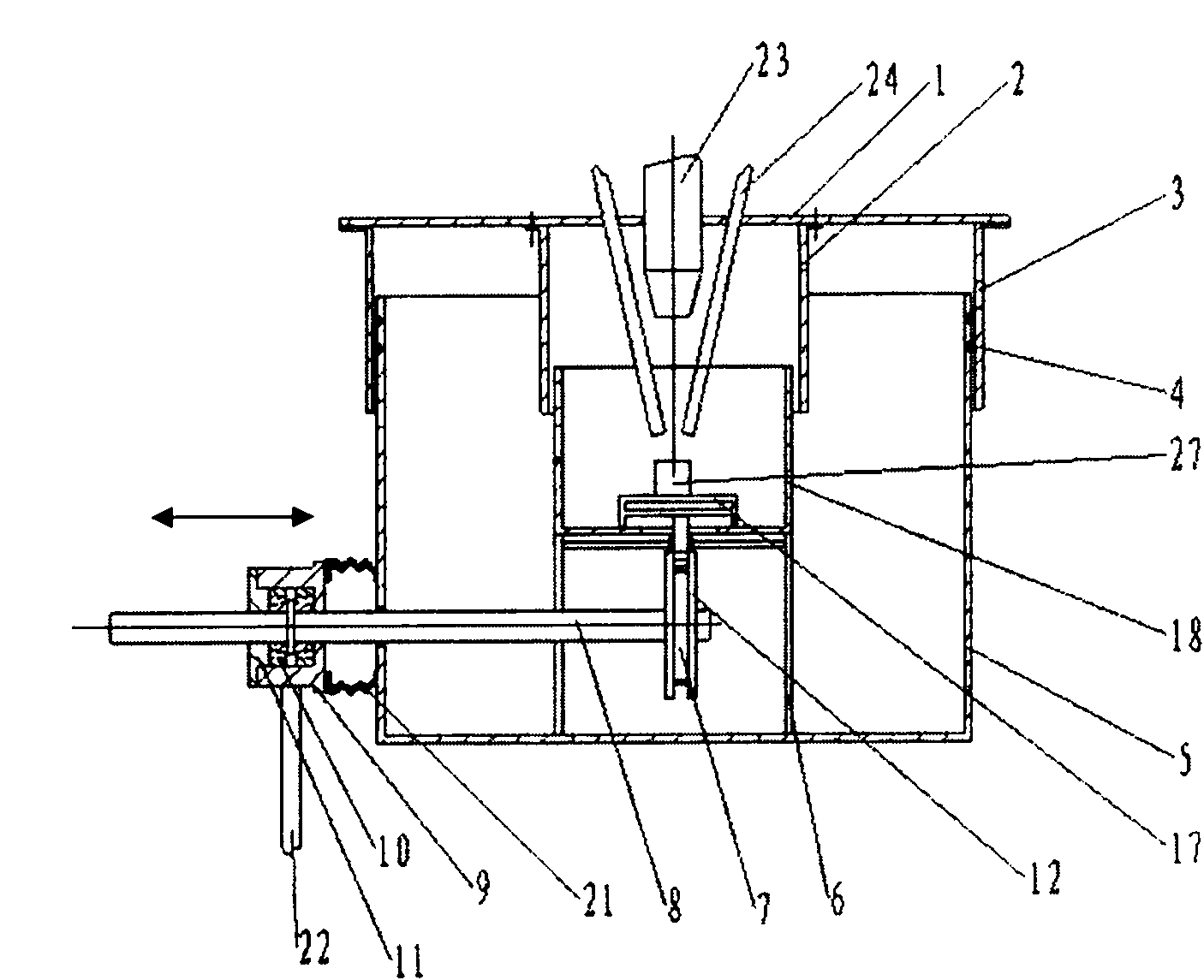

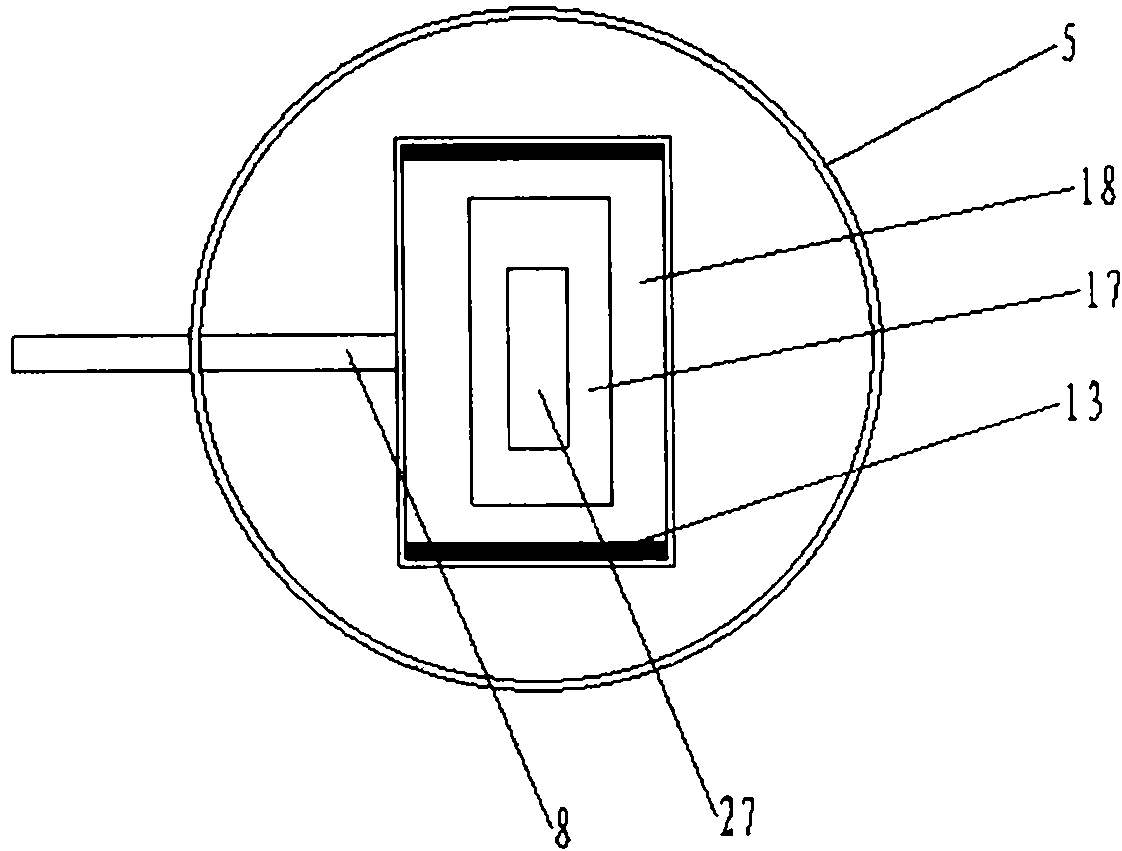

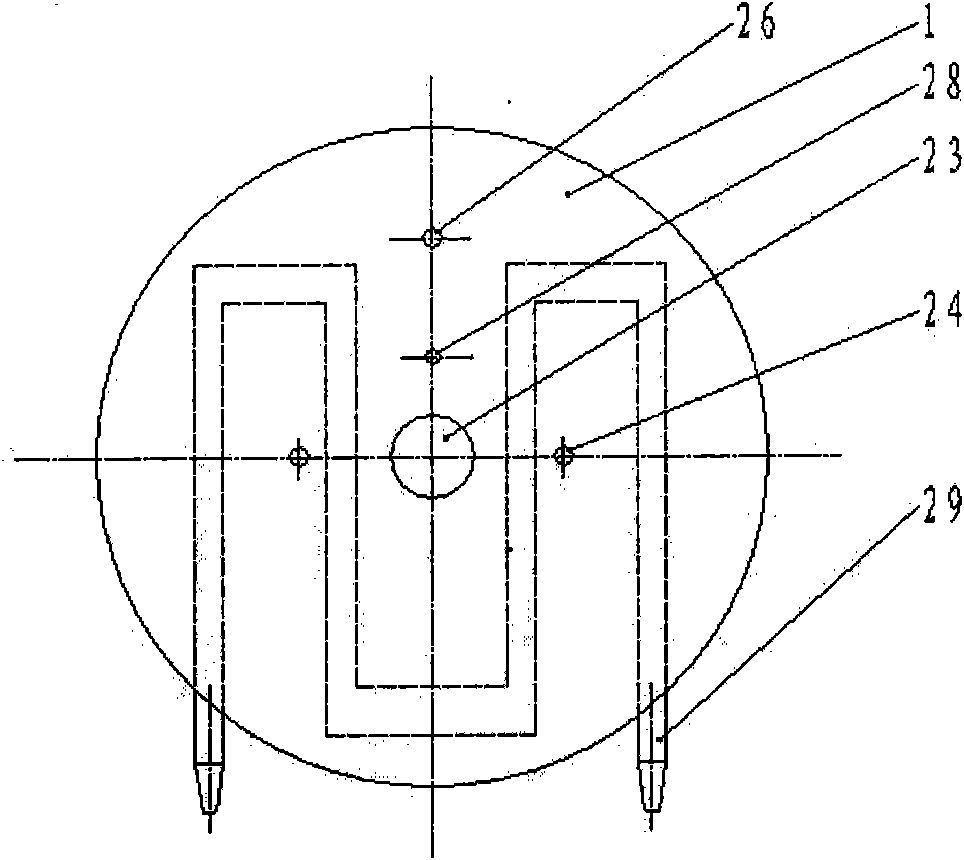

[0019] figure 1 , 2 It is an embodiment disclosed by the present invention. The controllable ambient temperature inert atmosphere laser material preparation and forming box mainly processes non-rotating workpieces, and the forming box includes a heating box 18, an inert atmosphere protection box and a temperature control device. Described heating box 18 is placed on the support 6, and the surrounding of heating box 18 is double-layer structure, fills asbestos in surrounding double-layer structure, and heating plate 13 is equipped with on the inner wall of heating box 18 front and back. The lower surface of the circular upper cover 1 of the inert atmosphere box is welded with a circular outer cylinder 3 and a square cylinder 2, the square cylinder 2 is arranged in the circular outer cylinder 3, and the upper surface of the circular upper cover 1 is welded with Cooling water pipe 29, sealing ring 4 is set between circular outer cylinder 3 and cylindrical box body 5, air-fillin...

Embodiment 2

[0021] Figure 6 , 7 , 8 is the second embodiment disclosed by the present invention, the controllable ambient temperature inert atmosphere laser material preparation and forming box mainly processes rotary workpieces. The structure of this embodiment is basically the same as that of Embodiment 1. The gear 7, the rack 15 and the workbench 17 in the heating box 18 are removed, and one end of the transmission shaft 8 in the heating box 18 is installed through a coupling that needs surface cladding. Swivel workpiece 19.

[0022] work process

[0023] First install the laser head 23 and the powder feeding tube 24, adjust the powder feeding tube 24 to adjust the powder focus to coincide with the laser focus, and then connect the sealing sleeve 3, the heat insulation box 2, and the circular upper cover 1 through bolts. Place the heating box 18 in the sealing cylinder 5 of the inert atmosphere box, and then put the circular upper cover 1 on the sealing flange of the sealing cylind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com