Belt wheel groove automatic detection instrument

A detector and automatic technology, which is applied in the field of size measuring instruments, can solve the problems of inaccurate measurement of the depth of the wheel groove and the shape and size of the groove, and achieve the effects of fast speed, convenient use and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

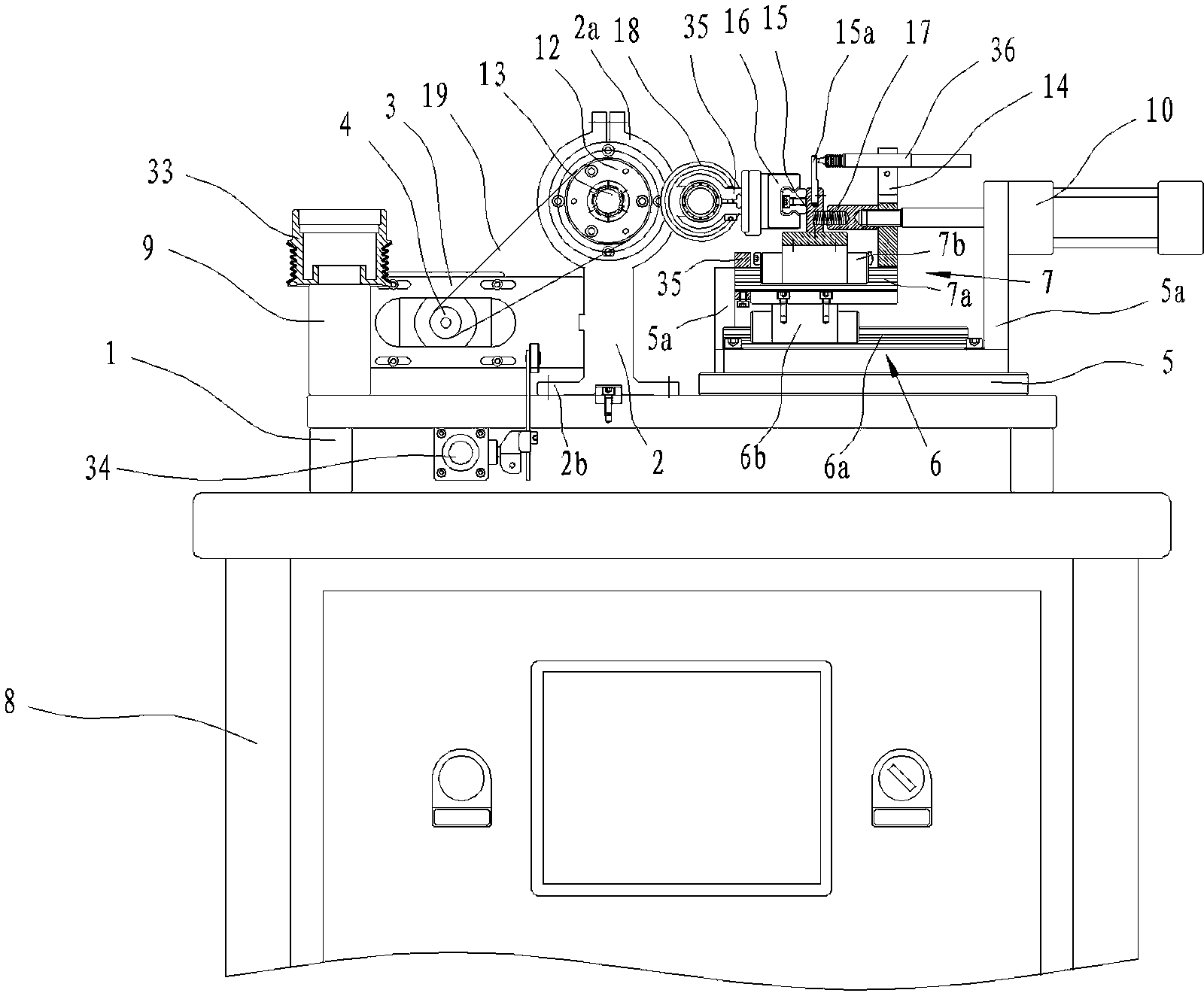

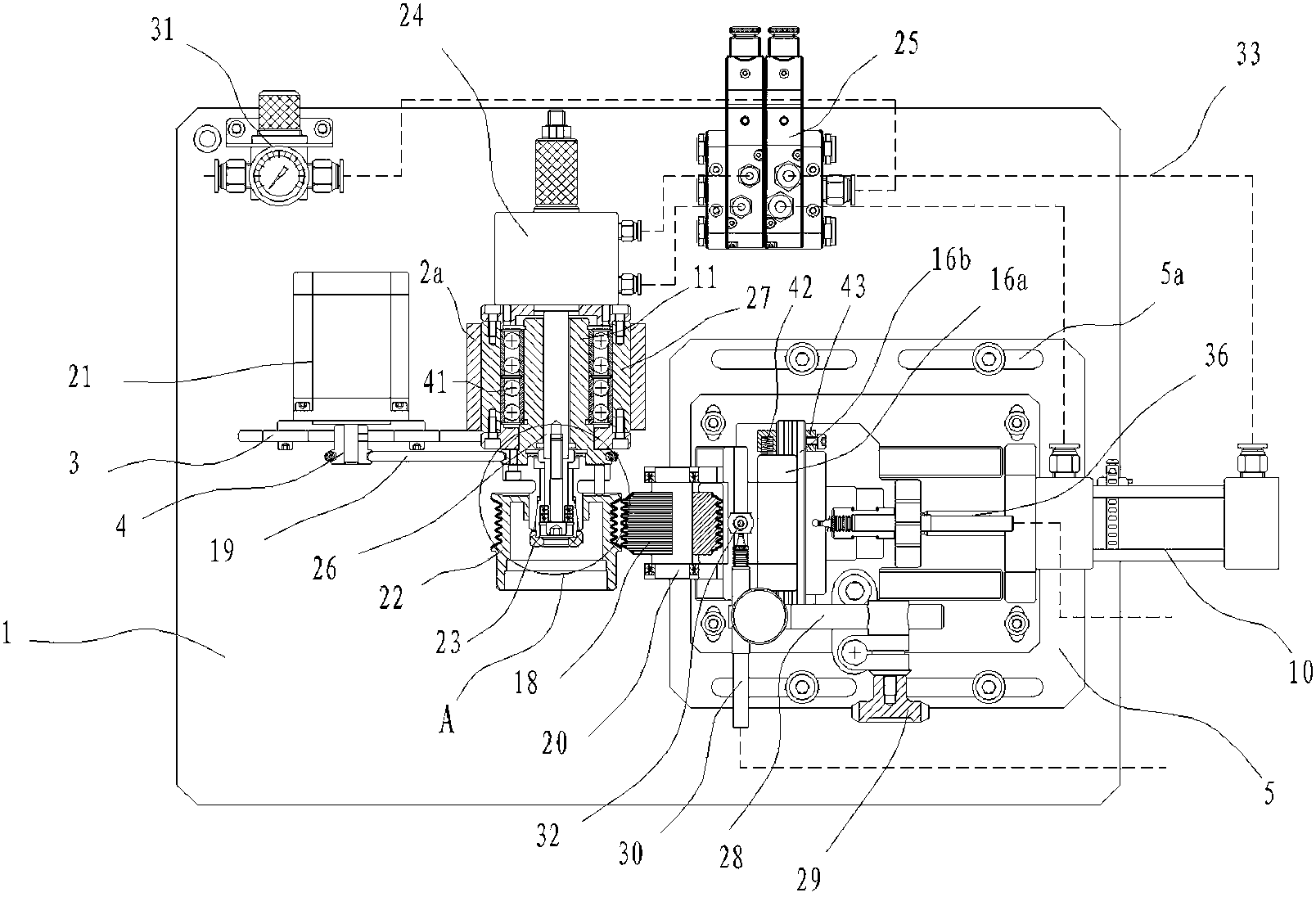

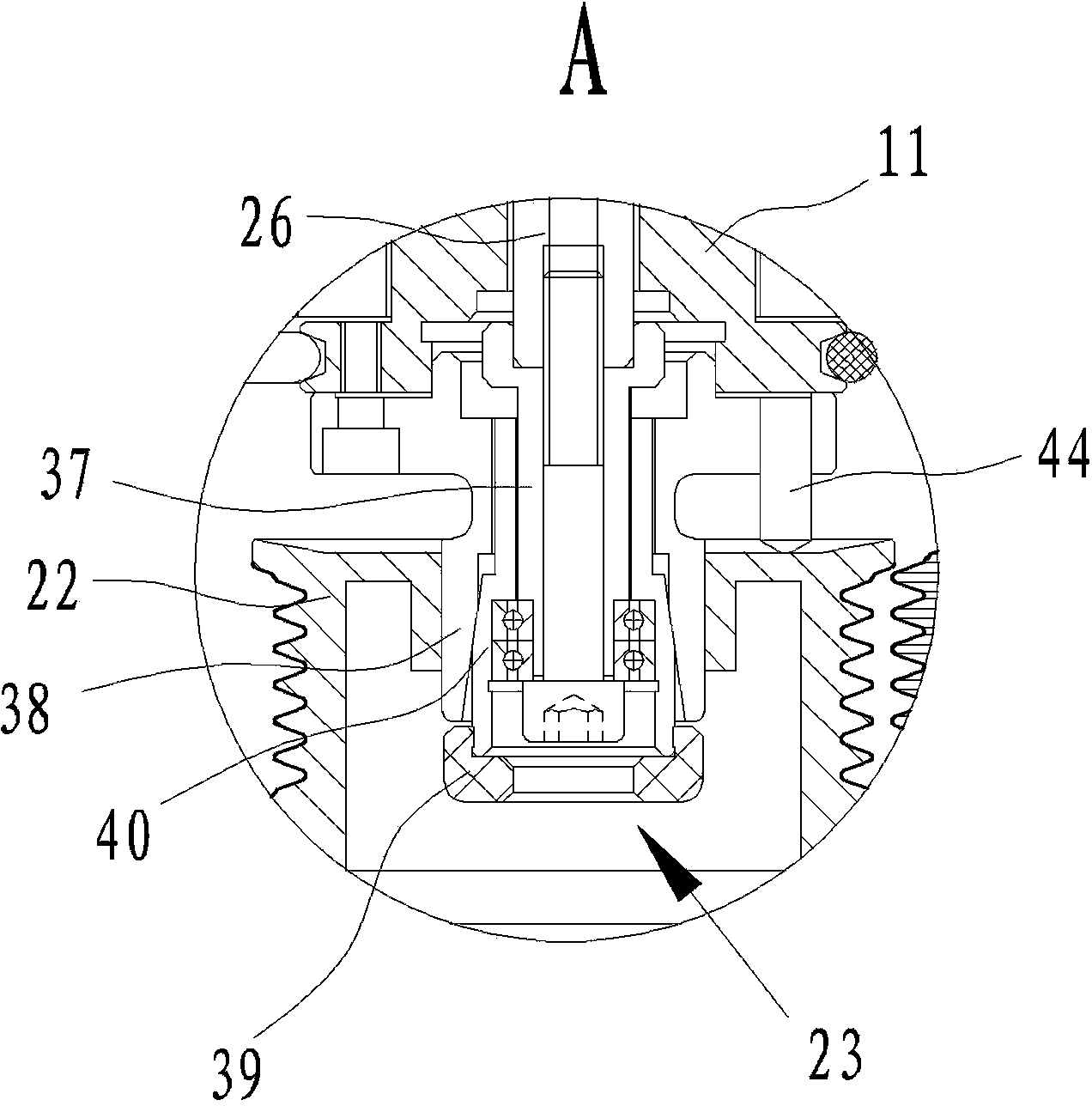

[0022] Such as figure 1 and figure 2 As shown, the pulley groove automatic detector provided by the present invention is characterized in that comprising:

[0023] a, detector 8, the frame 1 is connected to the upper end face of the detector 8, the frame 1 includes symmetrically arranged legs and a base plate connected on the legs, and a column 2, a vertical plate 3 and a fixed rod 9 are respectively connected on the base plate, so The column 2 and the vertical plate 3 described above are correspondingly matched, and a base 5 is also connected on the frame 1, and eight adjustment holes 5a are arranged symmetrically around the base 5, and the base 5 is fixed on the bottom of the support 1 by the bolts provided in the adjustment holes. On the bottom plate, the base 5 can be adjusted forward, backward, left and right through the adjustment hole 5a.

[0024] b. Set four vertical plate adjustment holes symmetrically on the vertical plate 3, connect the motor 21 on the vertical p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com