Fixing clamp for laser service life testing

A technology for life testing and fixing fixtures, which is applied in the direction of optical instrument testing, machine/structural component testing, instruments, etc. It can solve problems such as cumbersome operation, inconvenient series connection, complex structure, etc., to overcome electrical connection, high use value, Make simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The embodiments of the present invention will be described in detail below in conjunction with the drawings.

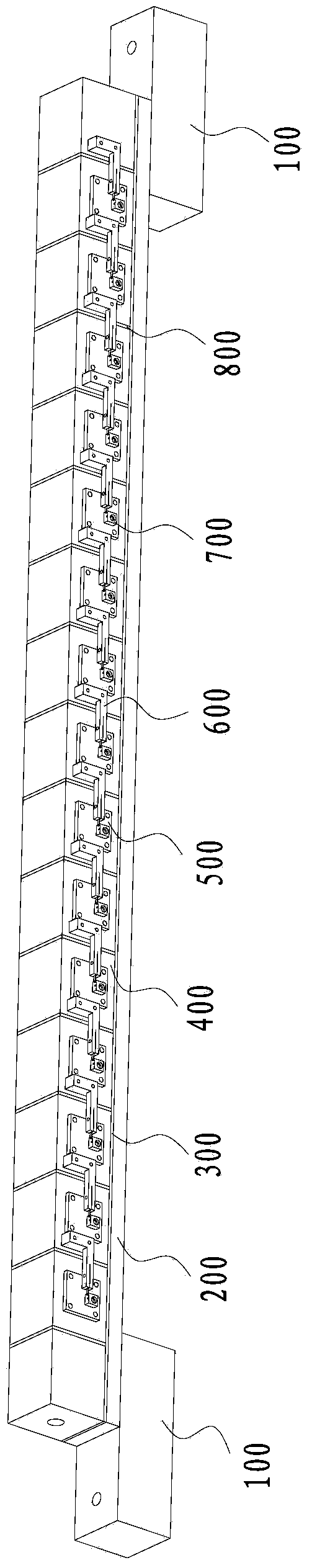

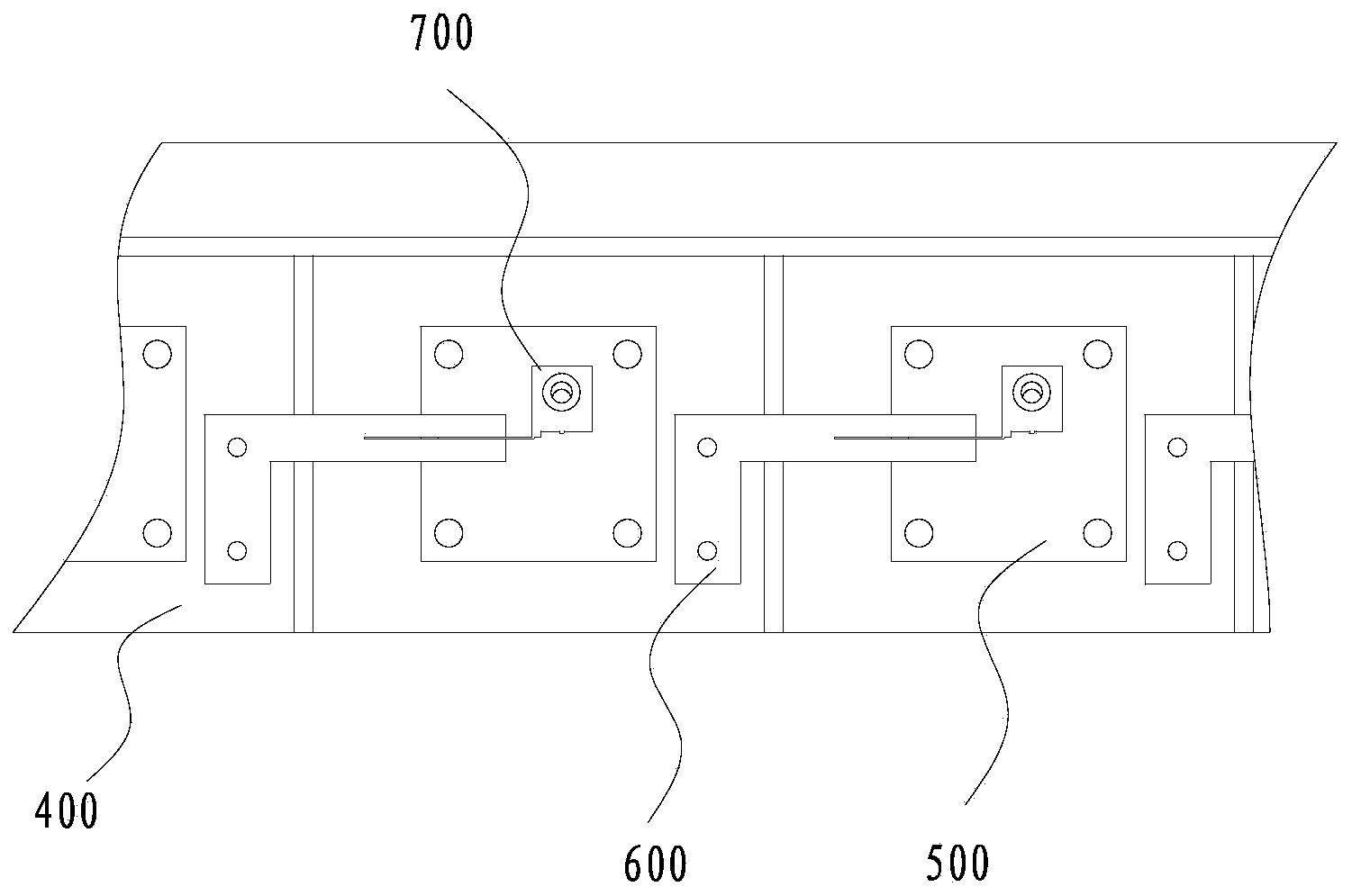

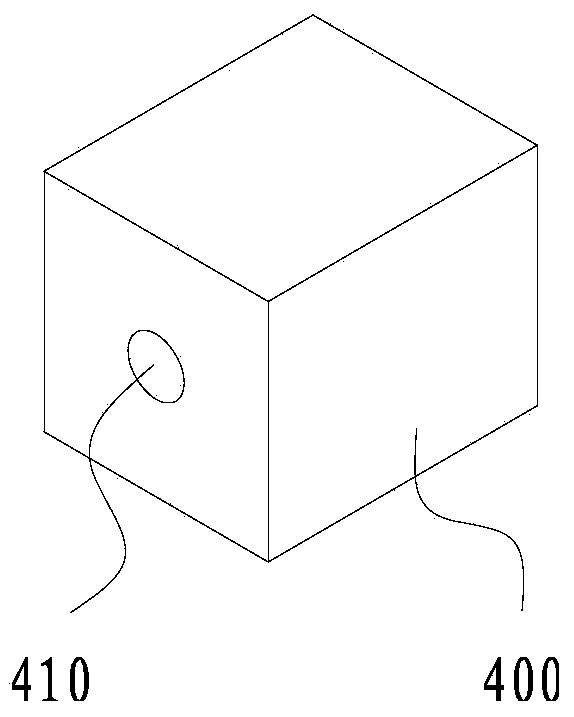

[0026] Such as figure 1 As shown, a fixing fixture for laser life testing can be used for C-Mount packaged single-die semiconductor lasers. It mainly includes a support frame 100, a mounting board 200 arranged on the support frame 100, and a plurality of mounting plates 200 mounted on the mounting board. The metal base 400 is provided with an insulating sheet 800 between every two metal bases 400, the metal base 500 is installed and fixed on the metal base 400, and a connector 600 for connecting the laser 700 on the adjacent base 400 is also installed.

[0027] A laser 700 is installed on the base 500 of each metal base 400, which can achieve the purpose of carrying out the life test on multiple packaged lasers 700 at the same time, and each base 400 is electrically insulated and separated by the insulating sheet 800. The metal base 500 on the base 400 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com