Polymer thin-film solar cell with laminated structure

A technology of solar cells and stacked structures, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as narrow absorption bands, energy loss, and low light absorption efficiency, and achieve the effect of improving energy conversion efficiency and improving matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

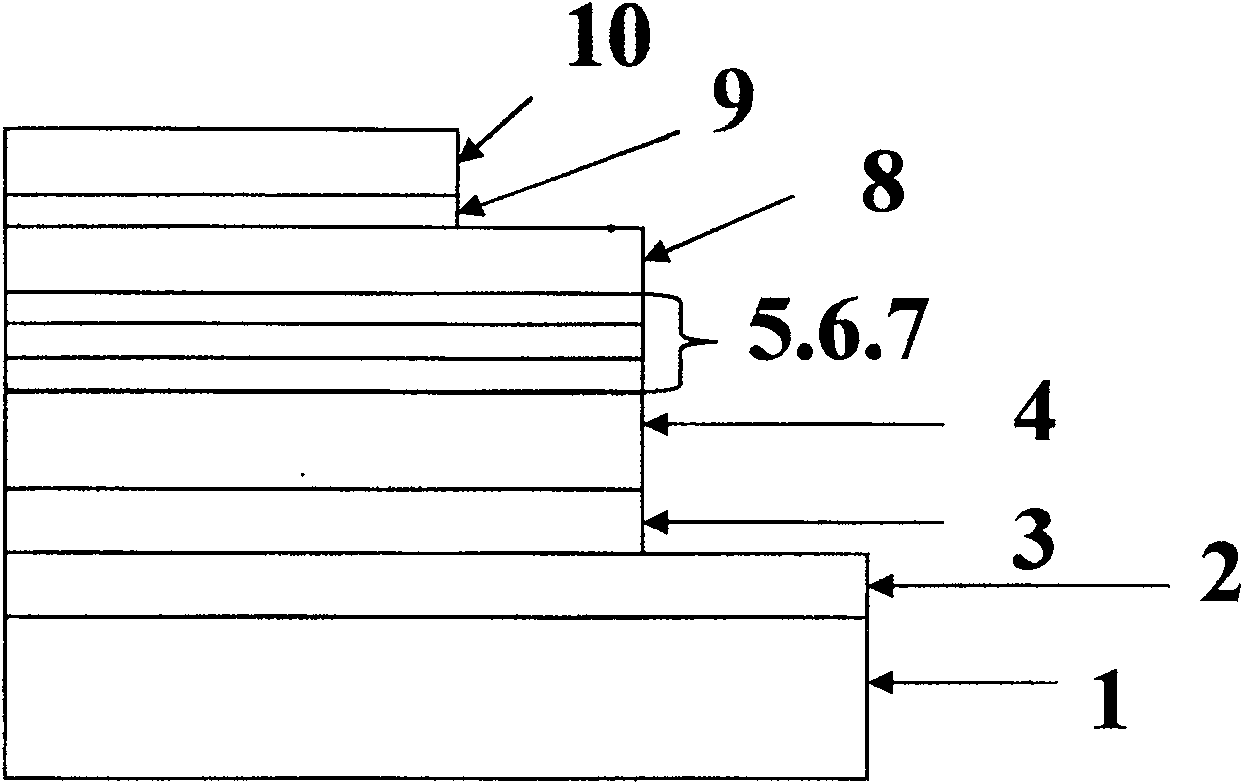

[0061] Using chlorobenzene as a solvent, the P3HT:PCBM mixed solution with a concentration of 18 mg / ml and PCBM accounting for 44% of the total mass was heated and stirred at 60°C for 3 hours, then stopped heating and continued to stir for 12 hours.

[0062] The ITO anode layer 2 and the glass substrate 1 form an ITO conductive glass, and the etched strip-shaped ITO conductive glass with a certain width is cleaned and dried. Place the clean ITO glass on the bracket of the spin coating machine, apply the PEDOT:PSS solution evenly to the entire sheet through a 0.45 micron filter head, and rotate at a speed of 3000 rpm for one minute to make the PEDOT:PSS on the ITO surface A thin film with a thickness of 40 nanometers was formed as the anode modification layer 3 and heated in an oven at 120° C. for 30 minutes.

[0063] Transfer the baked ITO substrate coated with PEDOT:PSS to the glove box, place it on the spin coater bracket after the substrate is cooled, and evenly coat the st...

Embodiment 2

[0068] With chlorobenzene as solvent, the concentration is respectively 10 mg / ml and 20 mg / ml, and the quality of PCBM accounts for 40% and 80% of the total mass of P3HT:PCBM mixed solution heated and stirred at 60 degrees for 3 hours, stop heating and continue Stir for 12 hours.

[0069] The ITO anode layer 2 and the glass substrate 1 form an ITO conductive glass, and the etched strip-shaped ITO conductive glass with a certain width is cleaned and dried. Place the clean ITO glass on the bracket of the spin coating machine, apply the PEDOT:PSS solution evenly to the entire sheet through a 0.45 micron filter head, and rotate at a speed of 5000 rpm for one minute to make the PEDOT:PSS on the ITO surface A thin film with a thickness of 20 nanometers was formed as the anode modification layer 3 and heated in an oven at 120° C. for 30 minutes.

[0070] The baked ITO substrate coated with PEDOT:PSS is transferred to the glove box, and after the substrate is cooled, it is placed on ...

Embodiment 3

[0075] With chlorobenzene as solvent, the concentration is respectively 10 mg / ml and 20 mg / ml, and the quality of PCBM accounts for 40% and 80% of the total mass of P3HT:PCBM mixed solution heated and stirred at 60 degrees for 3 hours, stop heating and continue Stir for 12 hours.

[0076] The ITO anode layer 2 and the glass substrate 1 form an ITO conductive glass, and the etched strip-shaped ITO conductive glass with a certain width is cleaned and dried. Place the clean ITO glass on the bracket of the spin coating machine, apply the PEDOT:PSS solution evenly to the entire sheet through a 0.45 micron filter head, and rotate at a speed of 1200 rpm for one minute to make the PEDOT:PSS on the ITO surface A thin film with a thickness of 100 nanometers was formed as the anode modification layer 3 and heated in an oven at 120° C. for 30 minutes.

[0077] The baked ITO substrate coated with PEDOT:PSS is transferred to the glove box, and after the substrate is cooled, it is placed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com