An inductive energy meter

An electric energy meter and inductive technology, applied in the field of inductive electric energy meters, can solve problems such as large fluctuations, and achieve the effects of reducing nonlinear errors, reducing errors, and small iron core silicon steel reluctance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: Applied to single-phase induction electric energy meter

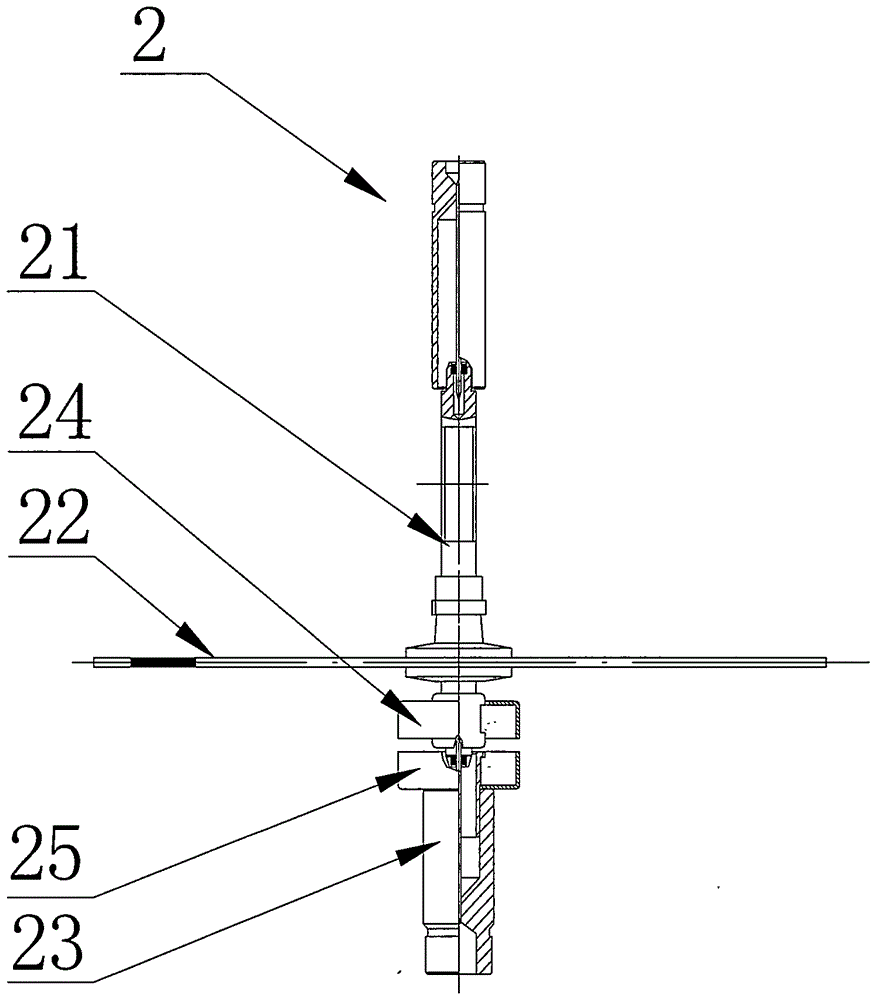

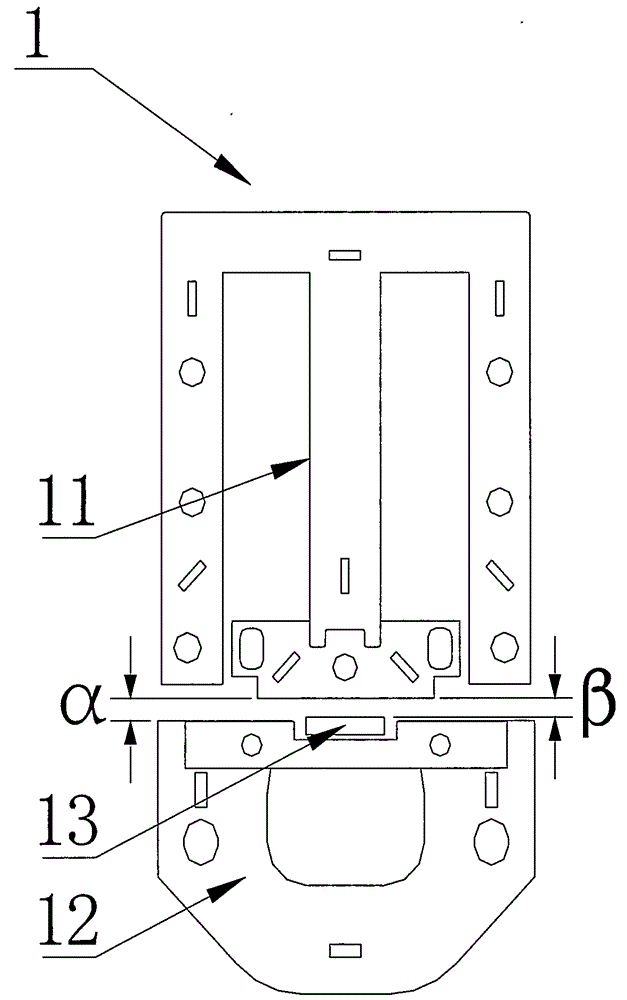

[0034] see figure 1 and figure 2 , a single-phase induction electric energy meter, including a driving element 1 and a rotating element 2, the rotating element 2 includes a rotating shaft 21, a rotating disk 22 and a lower shaft tip 23, the rotating disk 22 is movably connected with the rotating shaft 21; an upper magnetic ring 24 is arranged below the rotating disk 22 , the upper magnetic ring 24 is movably connected with the rotating shaft 21; the top of the lower shaft tip 23 is provided with a lower magnetic ring 25, and the lower magnetic ring 25 is fixedly connected with the lower shaft tip 23; the driving element 1 includes a voltage element 11, a current element 12 and a magnetic branch 13, the magnetic shunt 13 is arranged between the voltage element 11 and the current element 12, the distance α between the voltage element 11 and the current element 12 is 2.6 millimeters, and the distanc...

Embodiment 2

[0040] Embodiment 2: Applied to three-phase induction electric energy meter

[0041]Since the structure of the three-phase induction electric energy meter is similar to that of the single-phase induction electric energy meter, the structure of the three-phase induction electric energy meter is not shown in the drawings; the three-phase induction electric energy meter includes the driving element and the rotating element, and the rotating element It includes a rotating shaft, a turntable and a lower shaft tip, and the turntable and the rotating shaft are flexibly connected; an upper magnetic ring is arranged under the turntable, and the upper magnetic ring is flexibly connected with the rotating shaft; a lower magnetic ring is arranged on the top of the lower shaft tip, and the lower magnetic ring is connected to the lower shaft tip Fixed connection; the driving element includes a voltage element, a current element, and a magnetic shunt. The magnetic shunt is arranged between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com