Connecting assembly of USB 3.0 type optical fiber connector

A technology of USB3.0 and optical fiber connector, which is applied in the coupling of optical waveguide, fiber mechanical structure, etc., can solve the problems of easy damage and low tensile strength, and achieve wide application range, convenient manufacture and high tensile strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described and illustrated below in conjunction with the accompanying drawings and embodiments.

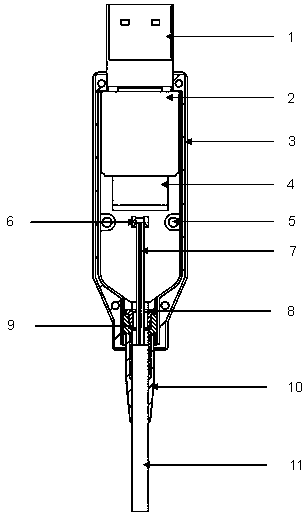

[0034] It includes a connecting joint, a tensile high-speed optical fiber data transmission cable 11 connected to the connecting joint, and a connector packaging shell 3 for installing the connecting joint.

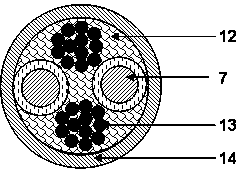

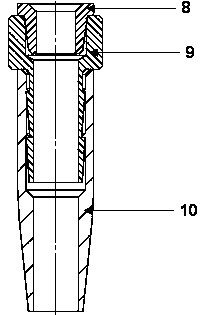

[0035] The optical cable as figure 2As shown, it includes an outer sheath 14, the outer sheath is made of flame-retardant TPU material, the thickness of one side is 0.64mm, and the outer diameter of the outer sheath is 2.98mm; the outer sheath is coated with two optical fibers 7, and the optical fiber It is a tight-buffered optical fiber, and the resin-coated optical fiber is coated with a tight-buffered layer. The material of the tight-buried fiber is acrylic resin. Optical fiber, the 850nm window transmission bandwidth is 418MHz*Km, the 850nm window attenuation is 2.98dB / Km; the outer sheath is also coated with a metal strengthe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com