A flange production process

A production process and flange technology, applied in the field of flange production process, can solve the problems affecting the dimensional accuracy and surface finish of flanges, reducing the service life and accuracy of turning tools, and reducing the service life of lathes, so as to save production equipment and performance. The effect of uniform and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

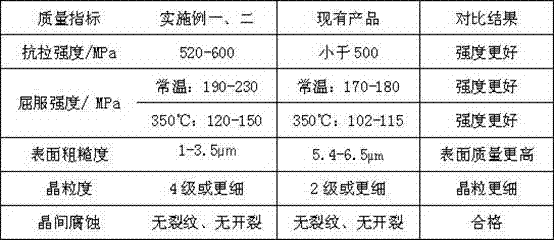

Examples

Embodiment 1

[0025] A flange production process, including flange forging blank and blank cutting forming, the steps are as follows:

[0026] a. After the raw material round bar is cut, it enters the electric furnace for heating, and adopts a four-stage heating method. The heating temperature of the first stage is 800°C, and the time is 12s; the heating temperature of the second stage is 950°C, and the time is 26s; the third stage The heating temperature of the stage is 850°C, and the time is 16s; the heating temperature of the fourth stage is 730°C, and the time is 30s;

[0027] b. After the heated raw material round bar is cooled to room temperature, put it into the punch press and forge it into the required flange shape;

[0028] c. Then put it into the friction press, and cold-extrude it on the mold to the basic size of the flange; and then undergo solid solution heat treatment to form a flange blank;

[0029] The solution heat treatment steps are as follows:

[0030] Heat the flange...

Embodiment 2

[0036] A flange production process, including flange forging blank and blank cutting forming, the steps are as follows:

[0037] a. After the raw material round bar is cut, it enters the electric furnace for heating. The heating adopts a four-stage heating method. The heating temperature of the first stage is 1150°C, and the time is 12s; the heating temperature of the second stage is 980°C, and the time is 22s; The heating temperature of the third stage is 900°C, and the time is 14s; the heating temperature of the fourth stage is 740°C, and the time is 20s;

[0038] b. After the heated raw material round bar is cooled to room temperature, put it into the punch press and forge it into the required flange shape;

[0039] c. Then put it into the friction press, and cold-extrude it on the mold to the basic size of the flange; and then undergo solid solution heat treatment to form a flange blank;

[0040] The solution heat treatment steps are as follows:

[0041] Heat the flange ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com