Highly flexible tow cable for port cranes

A port crane, highly flexible technology, applied in the direction of insulated cables, bendable cables, cables, etc., can solve problems such as uneven life cycle of cables, gaps in insulated cores, deformation of twisted cores, etc., to achieve high performance Stable, wear-resistant mechanical properties, strong tensile effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

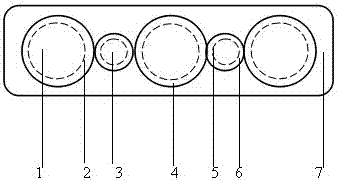

[0030] Such as figure 1 A high-flexible tow cable for port cranes as shown, includes a cable inner core and a sheath 7 wrapped outside the cable inner core, the cable inner core includes a power core and a control core, and the power core From inside to outside, it is composed of power line conductor 1, power line GRPP tape layer 2 and power line insulation layer 4. The control line core is composed of control line conductor 3, control line GRPP tape layer 5 and control line from inside to outside. An insulating layer 6 is formed. The cross-section of the high-flexible towing cable is rectangular, and there are 3 power cores. The power cores are arranged at intervals from left to right, and the control cores are arranged at the interval between adjacent power cores. The materials of power line conductors and control line conductors are Class 6 soft copper conductors that meet the GB / T3956-2008 standard. The GRPP tape layer of the power line and the GRPP tape layer of the con...

Embodiment 2

[0034] The present invention differs from Example 1 in that the material formulation of the sheath is as follows in parts by weight:

[0035] Thermoplastic elastomer (commercially available, Dalian Kemeng New Material Co., Ltd., brand XU2015N-90) 100 parts, S501A EPDM rubber (commercially available) 35 parts, polyolefin (linear low-density polyethylene, commercially available) 18 parts , 40 parts of reinforcing filler (calcined clay, commercially available), 7 parts of antioxidant (antioxidant DSTP, commercially available), 15 parts of cold-resistant plasticizer (dioctyl adipate, commercially available), coupling agent (silane coupling agent KH-590, commercially available) 2 parts, crosslinking agent (crosslinking agent BIPB, commercially available) 8 parts, carbon black 35 parts.

[0036] Others are with embodiment 1.

Embodiment 3

[0038] The present invention differs from Example 1 in that the material formulation of the sheath is as follows in parts by weight:

[0039] Thermoplastic elastomer (commercially available, Dalian Kemeng New Material Co., Ltd., brand XU2015N-90) 100 parts, S501A EPDM rubber (commercially available) 32 parts, polyolefin (linear low-density polyethylene, commercially available) 16 parts , 38 parts of reinforcing filler (calcined clay, commercially available), 6 parts of antioxidant (antioxidant DSTP, commercially available), 13 parts of cold-resistant plasticizer (dioctyl adipate, commercially available), coupling agent (silane coupling agent KH-590, commercially available) 1.5 parts, crosslinking agent (crosslinking agent BIPB, commercially available) 7 parts, carbon black 32 parts.

[0040] Others are with embodiment 1.

[0041] The preparation method of sheath material of the present invention is:

[0042](1) First put the thermoplastic elastomer into the rubber mixer for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com