Mask set and method for detecting alignment precision by utilizing mask set

A technology for overlay accuracy and mask, which is applied in the field of photolithography and can solve problems such as inability to detect overlay accuracy, low work efficiency, and inability to detect mask offset.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Embodiments of the present invention provide a mask set and a method for detecting overlay accuracy using the mask set to provide a new type of mask set and a method for using the mask set to detect overlay accuracy.

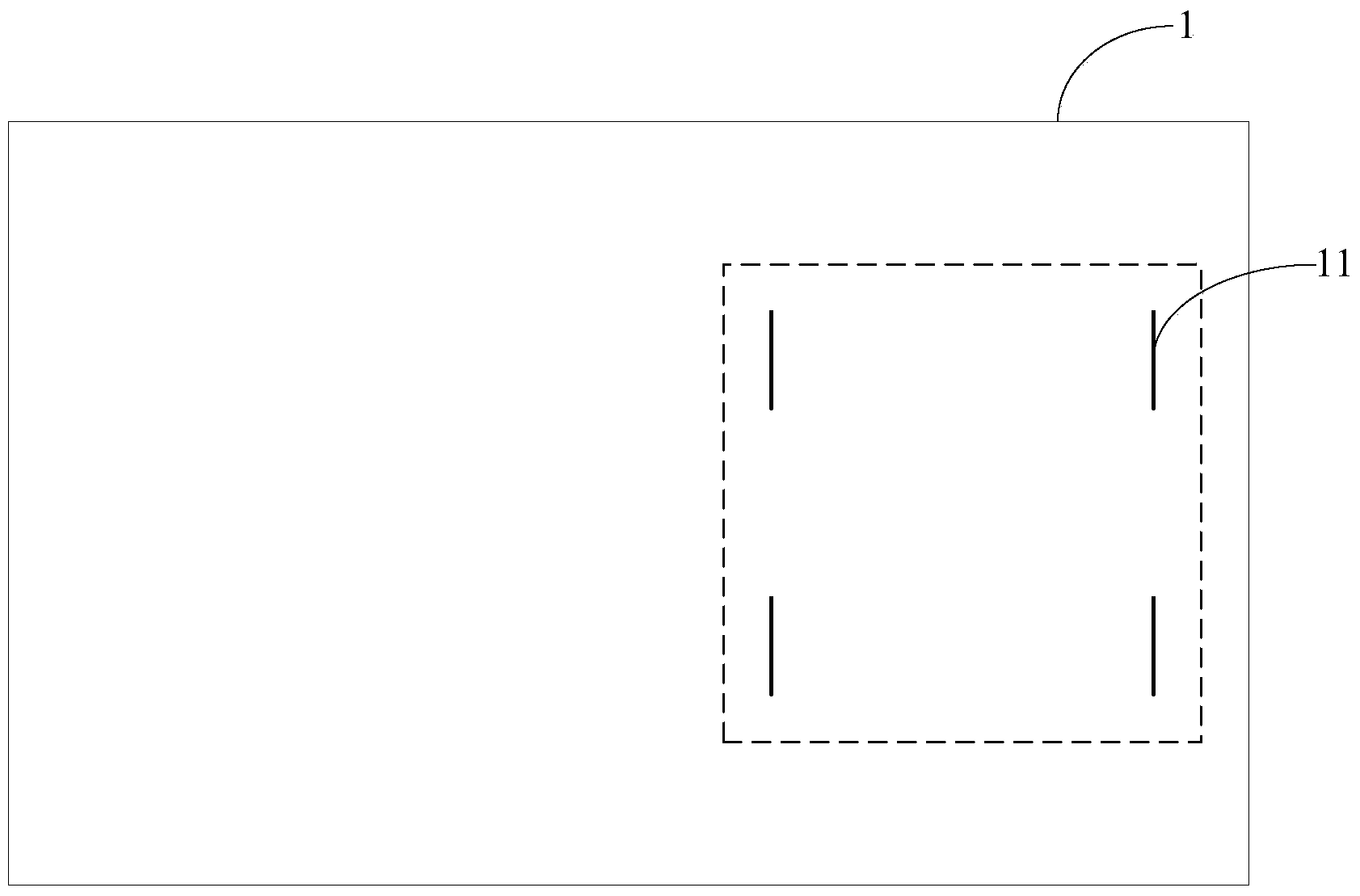

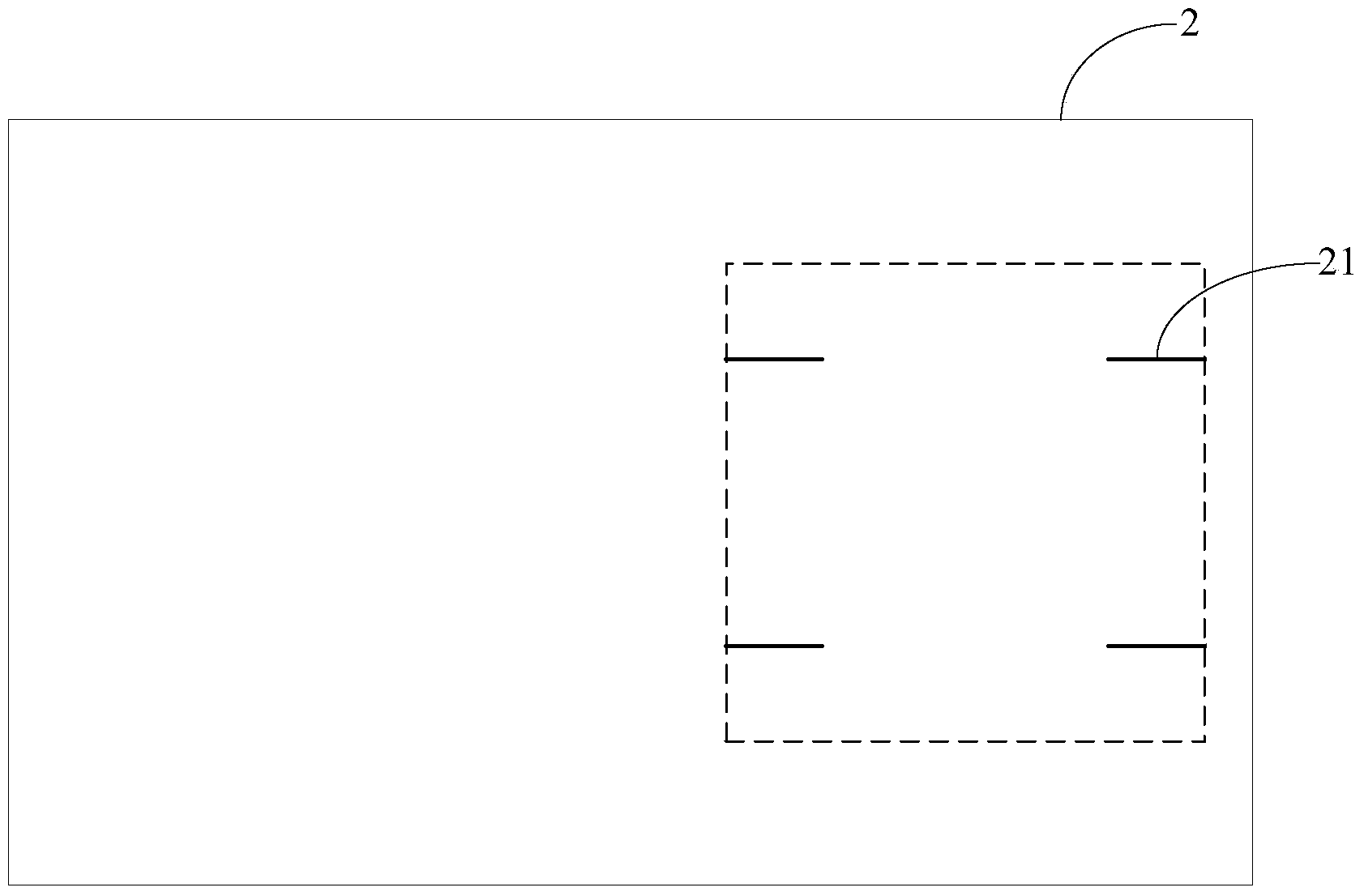

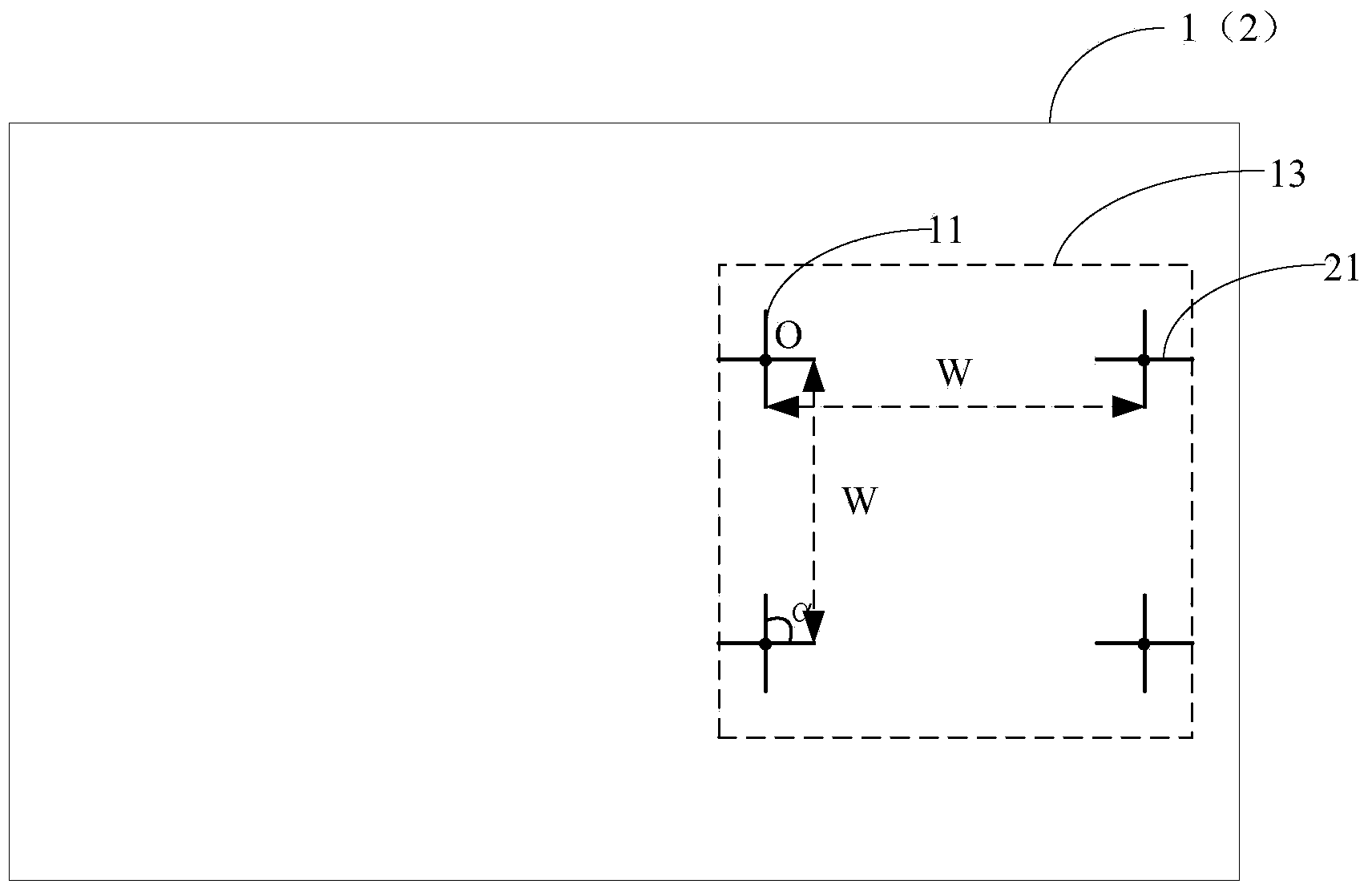

[0052] An embodiment of the present invention provides a novel mask set, including: a first mask and at least one second mask; a first set of markings is set on the first mask, and a second set of markings is set on the second mask Engraving marks, the first set of engraving marks and the second set of engraving marks are line segments with a set length, and an initial position is set for the first set of engraving marks and the second set of engraving marks, which corresponds to when there is no engraving deviation in lithography alignment position. Use microscopic equipment (such as a microscope, etc.) to detect whether the second overlay mark deviates from the initial position relative to the first overlay mark. If so, there is an overlay deviation, ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com