Intelligent motor controller, intelligent motor control method, externally connected circuit and motor remote controller thereof

A control method and motor technology, applied in the field of control method, intelligent motor controller, external circuit and its remote control, can solve problems such as delaying product delivery time, and achieve the effect of saving energy and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

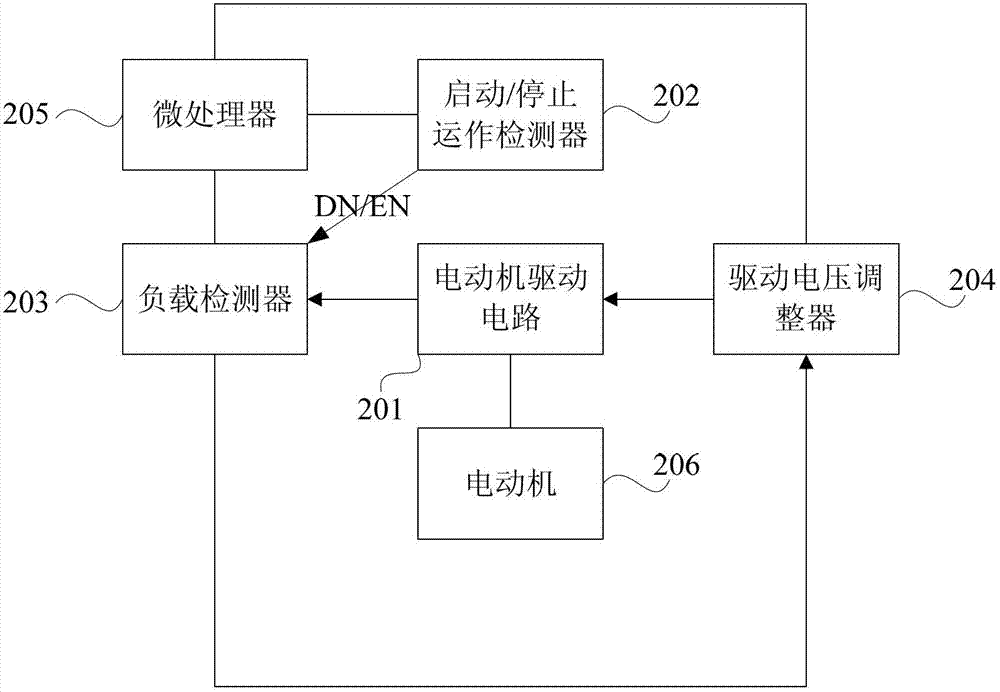

[0128] figure 2 It is a circuit block diagram of the intelligent motor controller according to the first embodiment of the present invention. Please refer to figure 2 , the intelligent motor controller includes a motor drive circuit 201 , a start / stop operation detector 202 , a load detector 203 , a drive voltage regulator 204 and a microprocessor 205 . In order to illustrate the spirit of the present invention conveniently, this figure additionally shows an electric motor 206 . The microprocessor 205 is coupled to the load detector 203 , the start / stop detector 202 , and the driving voltage regulator 204 for integrated control of the load detector 203 , the start / stop detector 202 , and the driving voltage regulator 204 . The motor drive circuit 201 is coupled to the motor 206 for driving the motor 206 . The start / stop operation detector 202 is used to determine the operation period of the motor 206. When the motor 206 starts to operate, it outputs a start signal EN, and...

no. 2 example

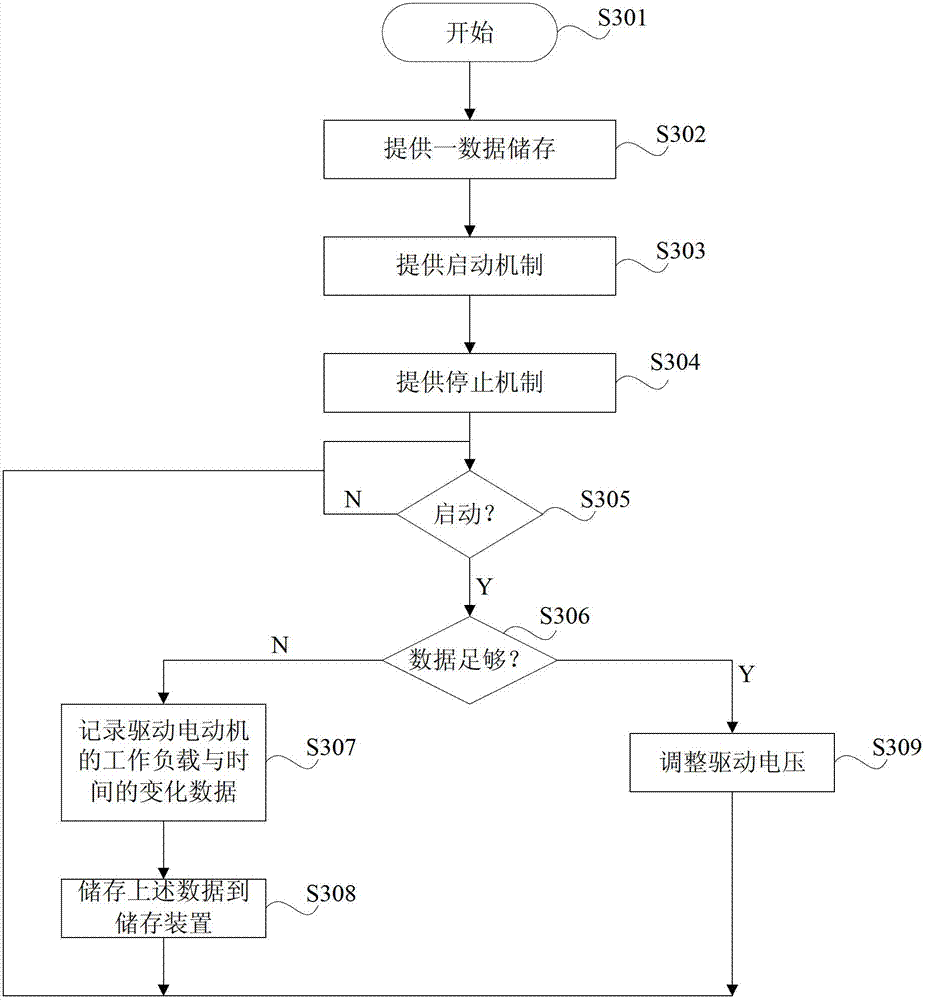

[0154] The above embodiments can be summarized into an intelligent motor control method. Please refer to image 3 , image 3 It is a flow chart of the intelligent motor control method according to the second embodiment of the present invention. Such as image 3 As shown, this intelligent motor control method includes the following steps:

[0155] Step S301: start.

[0156] Step S302: Provide a data storage device.

[0157] Step S303: Provide an operation activation mechanism.

[0158] Step S304: Provide an operation stop mechanism.

[0159] Step S305: Determine whether an operation activation mechanism (such as the above-mentioned EN signal EN) is received. If the judgment is "Yes", proceed to the next step S306, and if the judgment is "No", continue to proceed to Step S305.

[0160]Step S306: When receiving the operation activation mechanism, determine whether the data storage device has stored enough operation data. If not, go to step S307; if yes, go to step S309. ...

no. 3 example

[0165] The first embodiment and the second embodiment above provide a power-saving solution for industries and production lines. In this third embodiment, another frequency conversion solution for saving power on the frequency converter and saving production and development time is provided. Figure 4 Shown is the circuit block diagram of the external circuit of the inverter according to the third embodiment of the present invention. Please refer to Figure 4 The inverter external circuit includes a frequency conversion control module 401 , a control firmware 402 , an environment detector 403 , a display device 404 , a button group 405 and a microprocessor 406 . For the convenience of describing the present invention, in Figure 4 A motor driving circuit 407 and a motor 408 are additionally shown. The motor driving circuit 407 is used to drive the motor 408 . The frequency conversion control module 401 is used to control the operating frequency of the motor driving circuit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com