2D/3D analysis for abnormal tools and stage diagnosis

An anomaly and tool technology, applied in the field of semiconductor processing systems, can solve problems such as difficult to determine abnormal tool and stage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

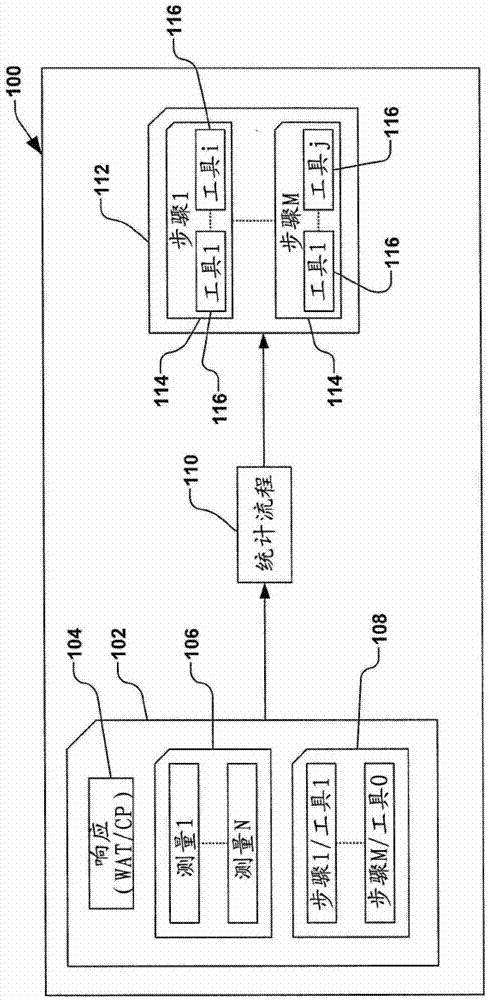

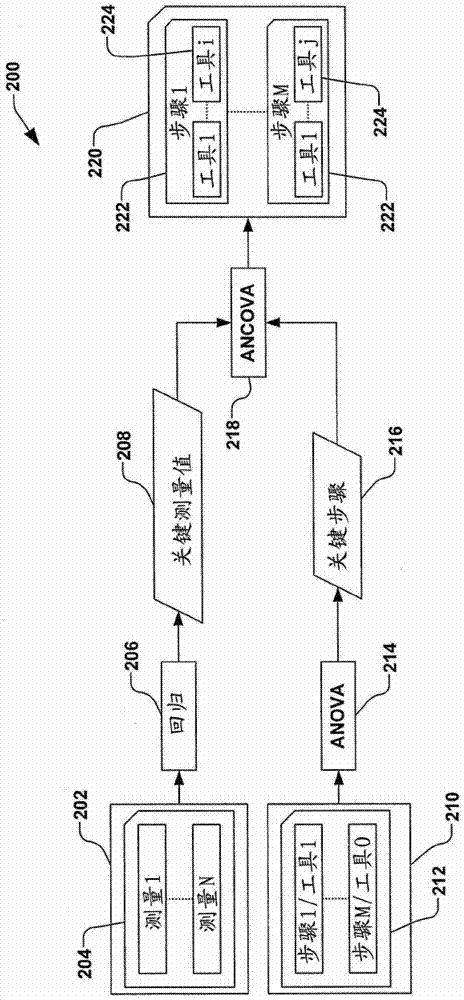

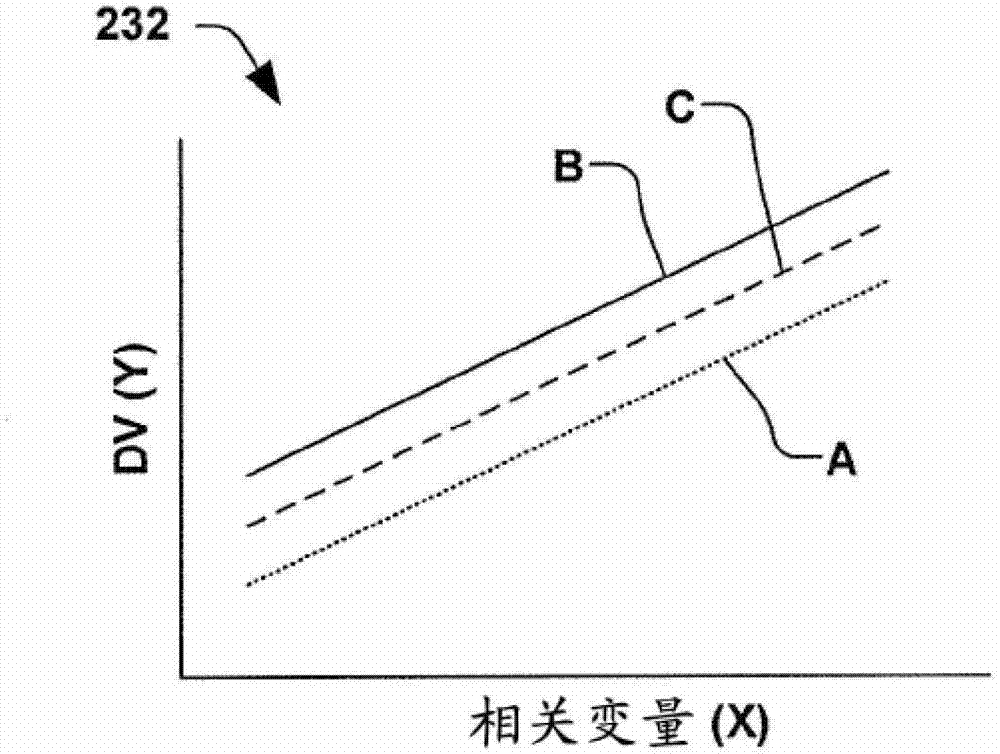

[0033] The present invention provides a multidimensional analysis flow to rank suspect tools and process steps in the absence of interference from other relevant factors or influences, such as processing in one step that may affect measurements in subsequent steps. Accordingly, the present invention provides a method of efficiently sequencing tools and process steps in the order of the anomalies demonstrated in each corresponding tool and process step.

[0034] Accordingly, the following description refers to the accompanying drawings, wherein like reference numerals are generally used to designate like elements throughout, the various drawings not necessarily being drawn to scale. In the following description, for purposes of explanation, numerous specific details are set forth to facilitate understanding. It will be understood, however, by those skilled in the art that one or more aspects described herein may be practiced with a lesser degree of these specific details. In o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com