Material surface defect detection method based on compressed sensing

A defect detection, compressed sensing technology, applied in image data processing, instrumentation, computing and other directions, can solve problems such as lack of prior information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with accompanying drawing and embodiment, the present invention is described in detail:

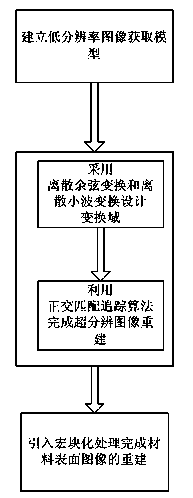

[0037] like figure 1 As shown in the super-resolution image acquisition and reconstruction process flow chart of the present invention, a method for detecting material surface defects based on compressed sensing in the present invention includes the following specific steps:

[0038] The design of the system model is based on the principle of compressed sensing to perform super-resolution reconstruction of time and space domain sub-image mapping, and finally hand it over to the high-order neuron bionic unit for identification and detection.

[0039] First, build a low-resolution image acquisition model:

[0040] Y = KJX (1)

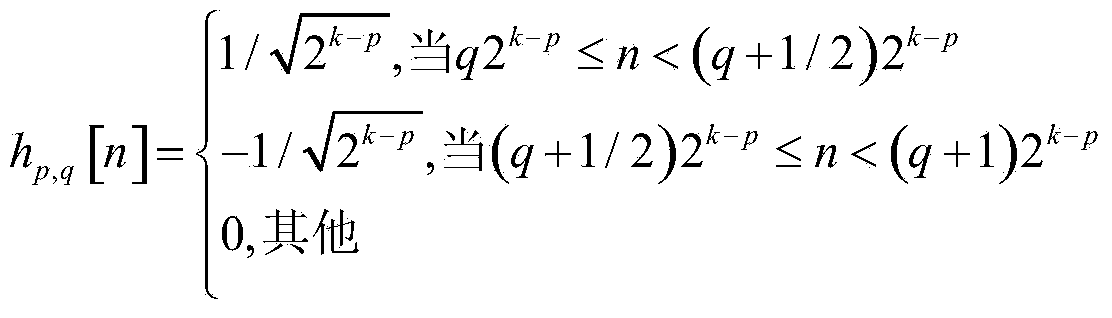

[0041] Among them, Y represents the low-resolution image acquired by the system; X represents the original information; J represents the degradation process of the original information in the bionic system; K represents the sampling oper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com