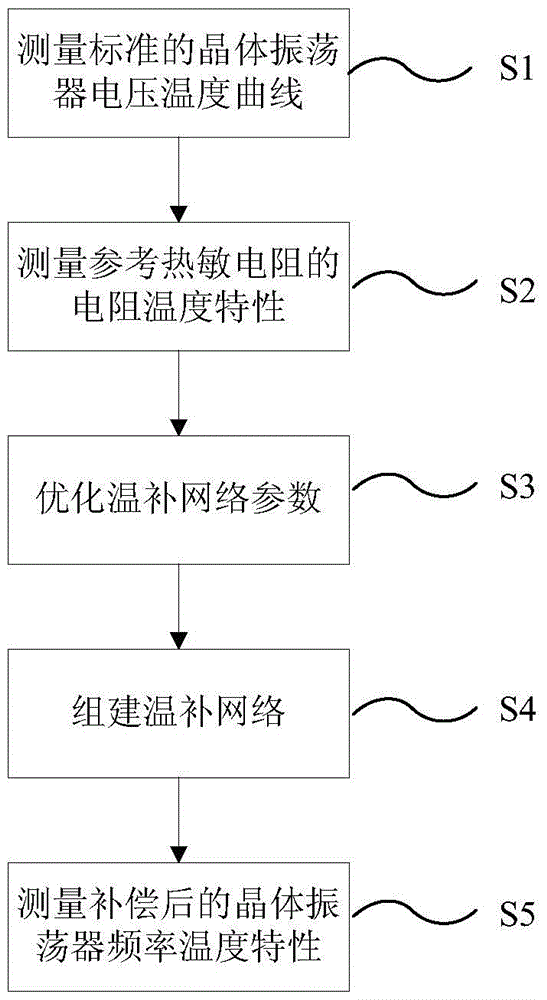

A Temperature Compensation Method for Analog Temperature Compensated Crystal Oscillator

A technology for simulating temperature compensation and crystal oscillators, applied in the field of temperature compensation, can solve the problems of low one-time success rate of temperature compensation, and achieve the effect of improving the effect, reducing the production cost and improving the reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

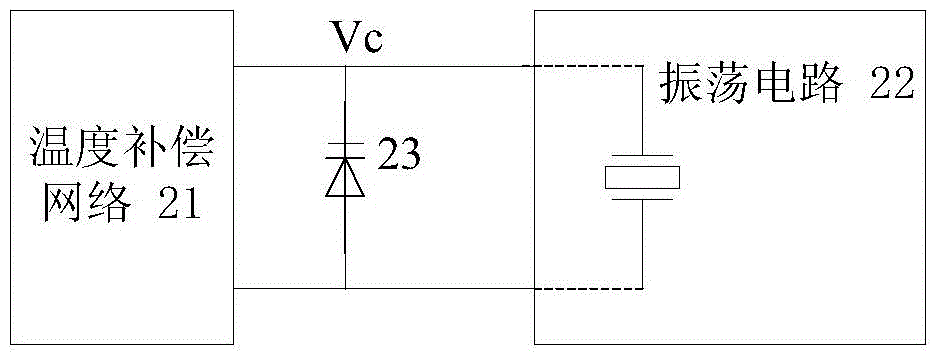

[0036] Put the crystal oscillator in the incubator, adjust the control voltage of the varactor diode (23) in the crystal oscillator, so that the frequency of the crystal oscillator reaches the nominal value at each temperature point, and record the control voltage at each temperature point value, forming the voltage-temperature curve data for an uncompensated crystal oscillator.

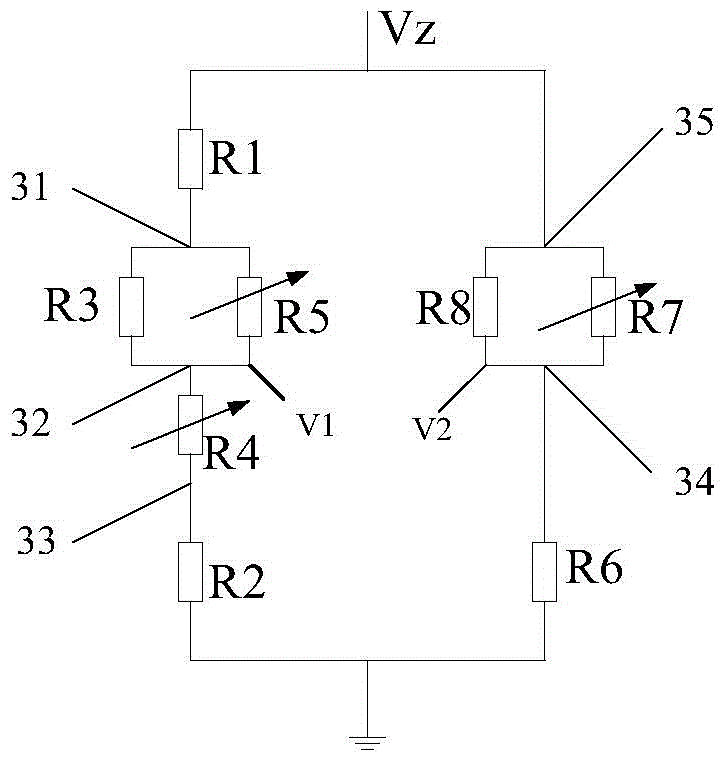

[0037] The reference thermistor adopts an online test method, and the reference thermistor test circuit adopts a form similar to the temperature compensation network. Such as image 3 As shown, the input of this test circuit is applied with a fixed voltage V z , and select low and medium resistance thermistors as reference thermistors to connect to the positions of R5, R7 and R4 in the temperature compensation network respectively. During the online test of the thermistor, the online test can be roughly selected within the allowable range of the fixed resistance and the thermistor in the temperatur...

Embodiment 2

[0046] Put the crystal oscillator in the incubator, adjust the control voltage of the varactor diode (23) in the crystal oscillator, so that the frequency of the crystal oscillator reaches the nominal value at each temperature point, and record the control voltage at each temperature point value, forming the voltage-temperature curve data for an uncompensated crystal oscillator.

[0047] The reference thermistor adopts the online test method, and the reference thermistor test circuit adopts a form similar to the temperature compensation network, such as image 3 As shown, the input of this test circuit is applied with a fixed voltage V z , and select low and medium resistance thermistors as reference thermistors to connect to the positions of R5, R7 and R4 in the temperature compensation network respectively. During the online test of the thermistor, the online test can be roughly selected within the allowable range of the fixed resistance and the thermistor in the temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com