A full-distributed heat pipe heat removal cabinet

A fully distributed, heat pipe technology, used in cooling/ventilation/heating renovation, instruments, electrical and digital data processing, etc., can solve the problem of water cooling cabinet door water entering the machine room, etc., to ensure safety, improve safety, and efficiently remove heat. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

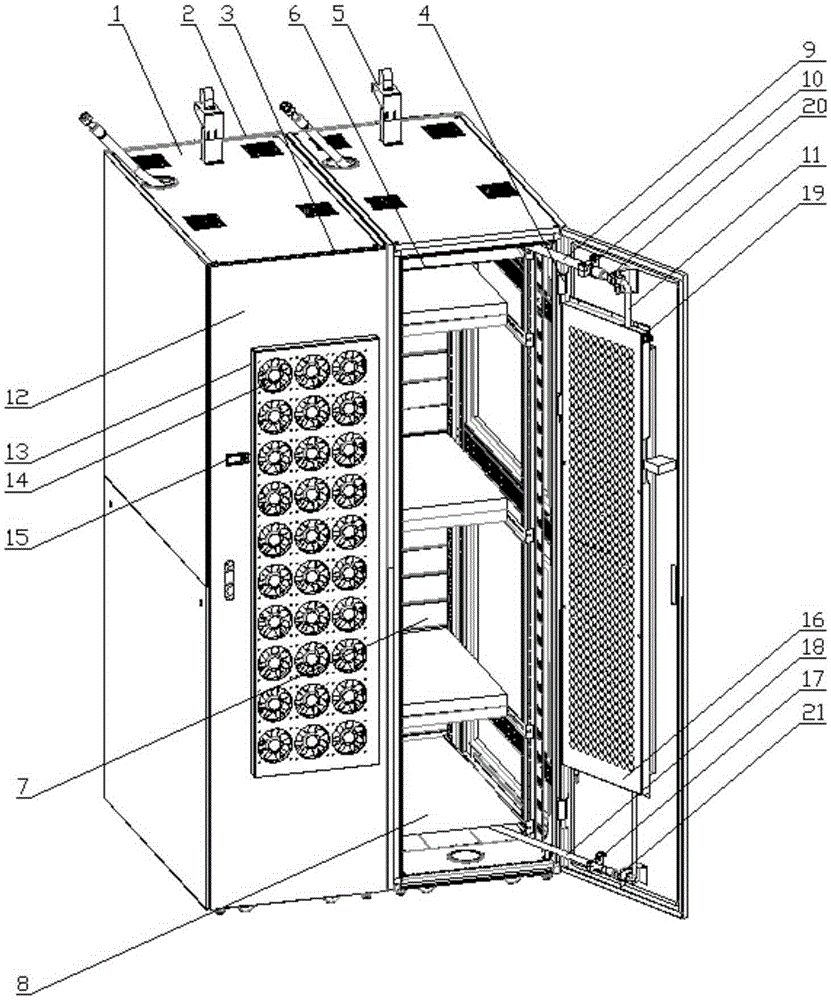

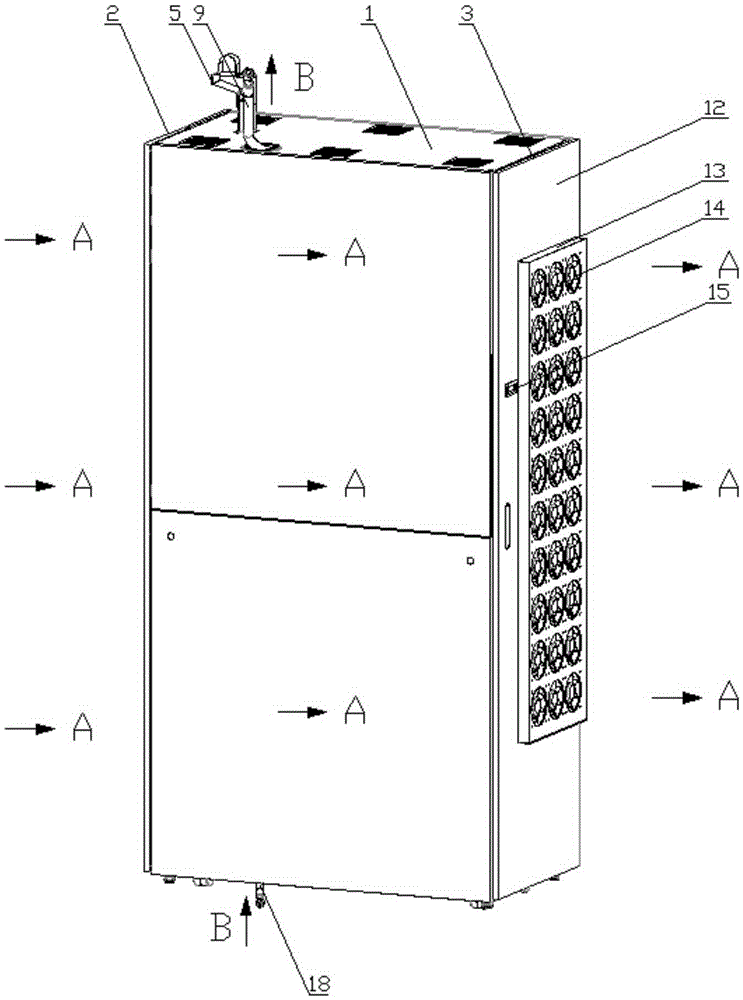

[0021] figure 1 It is a structural schematic diagram of the full-distributed heat exhaust cabinet of the present invention. The full cloth heat exhaust cabinet of the present invention includes a movable bracket 1 with side panels, a mesh front door 2, a back panel 3, a reinforced hinge 4, a height-adjustable header bracket 5, a trachea hose partition 6, and a sealing assembly 7. Liquid pipe hose partition 8. Among them, the back panel 3 is composed of a trachea hose 9, a trachea fixing assembly 10, a heat pipe heat exchanger 11, a back panel frame sheet metal 12, a fan mounting plate 13, a small axial flow fan 14, a controller 15, and a mesh cover plate 16. The liquid pipe fixing assembly 17 is composed of a liquid pipe hose 18; the heat pipe heat ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com