Novel feed trough device capable of being used wetly and dryly

A dry and wet dual-purpose, feeding trough technology, applied in animal feeding devices, applications, animal husbandry, etc., can solve the problems of pigs rushing for food, feed waste, feed pollution, etc., to reduce labor costs and labor. , the effect of low feed waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

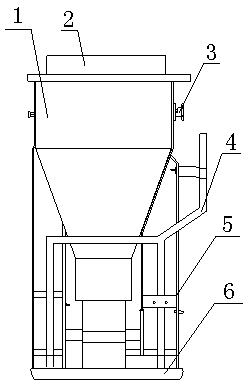

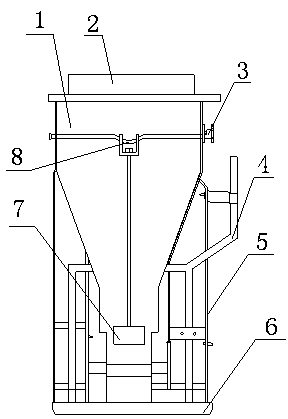

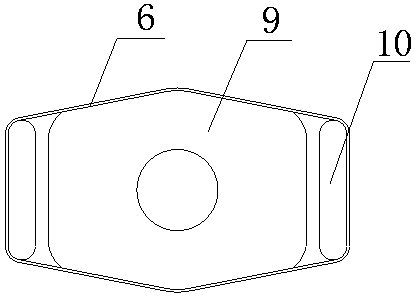

[0012] like figure 1 , 2 , shown in 3, a novel wet and dry feeding trough device, comprising a plastic bucket 1, a bung 2, a positioning frame 5, a stainless steel bottom basin 6, the positioning frame 5 is erected on the stainless steel bottom basin 6, and the positioning The water inlet pipe 4 is installed on the side of the frame 5, and the plastic bucket 1 is fixed inside the positioning frame 5. The upper part of the plastic bucket 1 is penetrated with a discharge adjustment rod 3 with a bump 8, and the regulator 7 is suspended below the bump 8. The top of the plastic bucket 1 is provided with bucket lid2. The middle of the stainless steel bottom basin 6 is a feed tank 9, and both sides are water tanks 10. The lower part of the plastic barrel 1 is designed with a conical angle. After the feed is poured into the plastic barrel 1, the feed slowly flows into the feed tank 9 from the gap between the regulator 7 and the discharge port. When the feed is stuck in the gap betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com