Preparation process of coco powder

A preparation process, coconut flour technology, applied in food preparation, food ingredients as emulsifier, food precipitation and other directions, can solve the problems of coconut flour taste influence, complicated enzymatic hydrolysis process, nutrient loss, etc., and achieves high powder yield and simplification. Process, raw material and cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

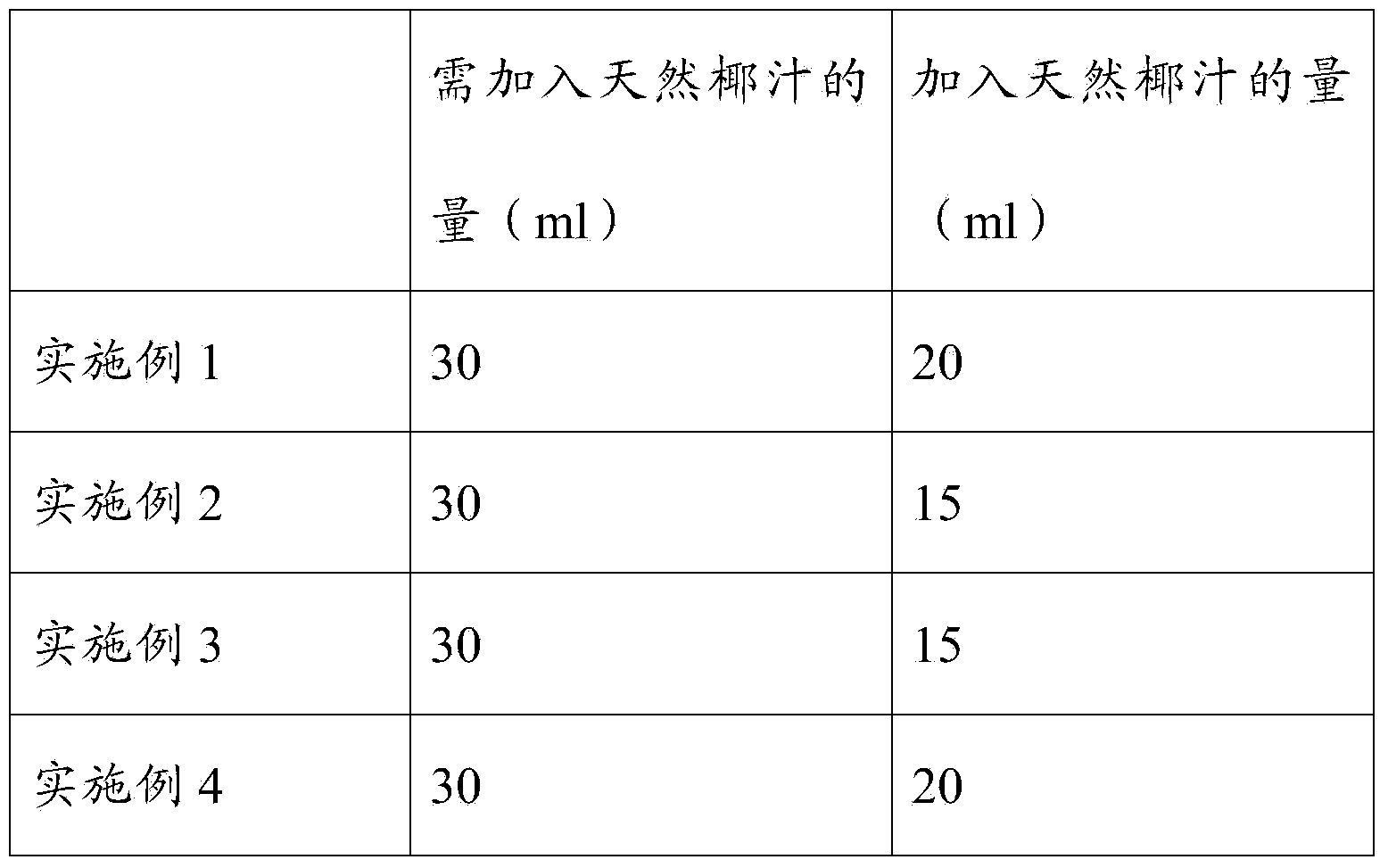

Embodiment 1

[0022] Follow the steps below to prepare coconut flour in turn:

[0023] (1) Firstly beat coconut meat and coconut milk to make coconut paste;

[0024] (2) Then use a grinder to refine the coconut paste, first perform 2 coarse grindings, and then 1 fine grinding;

[0025] (3) Use a high-pressure homogenizer to homogenize the coconut butter once under a pressure of 20MPa;

[0026] (4) Add emulsifier and emulsified starch to the coconut paste for mixing. The mass ratio of coconut paste, emulsified starch, and emulsifier is 85:10:7; the emulsifier is composed of monoglyceride, lactate and DATEM. Its mass ratio is: monoglyceride: lactate: DATEM=2:1:0.7.

[0027] (5) The solution after mixing the ingredients is subjected to two-stage high-pressure homogenization treatment. The first stage uses 20MPa pressure homogenization twice, and the second stage uses 5MPa pressure homogenization once to obtain a solution in a good emulsified state;

[0028] (6) Spray-dry the solution after ...

Embodiment 2

[0030] Follow the steps below to prepare coconut flour in turn:

[0031] (1) Firstly beat coconut meat and coconut milk to make coconut paste;

[0032] (2) Then use a grinder to refine the coconut paste, first for 4 times of coarse grinding, and then for 3 times of fine grinding;

[0033] (3) Use a high-pressure homogenizer to homogenize the coconut butter 4 times under a pressure of 30MPa;

[0034] (4) Add emulsifier and emulsified starch to the coconut paste for mixing. The mass ratio of coconut paste, emulsified starch, and emulsifier is 95:5:8; the emulsifier is composed of monoglyceride, lactate and DATEM. Its mass ratio is: monoglyceride: lactate: DATEM=1:3:0.5.

[0035] (5) The solution after mixing the ingredients is subjected to two-stage high-pressure homogenization treatment. The first stage uses 30MPa pressure homogenization twice, and the second stage uses 10MPa pressure homogenization once to obtain a solution in a good emulsified state;

[0036] (6) Spray-dry...

Embodiment 3

[0038] Follow the steps below to prepare coconut flour in turn:

[0039] (1) Firstly beat coconut meat and coconut milk to make coconut paste;

[0040] (2) Then use a grinder to refine the coconut paste, first perform 2 coarse grindings, and then 6 fine grindings;

[0041] (3) Use a high-pressure homogenizer to homogenize the coconut butter twice under a pressure of 20MPa;

[0042] (4) Add emulsifier and emulsified starch to the coconut paste for mixing. The mass ratio of coconut paste, emulsified starch, and emulsifier is 90:10:3; the emulsifier is composed of monoglyceride, lactate and DATEM. Its mass ratio is: monoglyceride: lactate: DATEM=3:1:0.8.

[0043] (5) The solution after mixing the ingredients is subjected to two-stage high-pressure homogenization treatment. The first stage uses 25MPa pressure homogenization for 6 times, and the second stage uses 7MPa pressure homogenization for 2 times to obtain a solution in a good emulsified state;

[0044] (6) Spray-dry the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com