A kind of preparation method of stewed meat without adding water

A production method and technology of stewed meat, applied in food preparation, food heat treatment, food science, etc., can solve the problems of cumbersome production process of stewed meat, waste of heat energy and water energy, and long-term cooking of products, so as to shorten the stewed time, The effect of saving production cost and using fewer types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0061] Implementation Case 1 The preparation method of braised pork without adding water

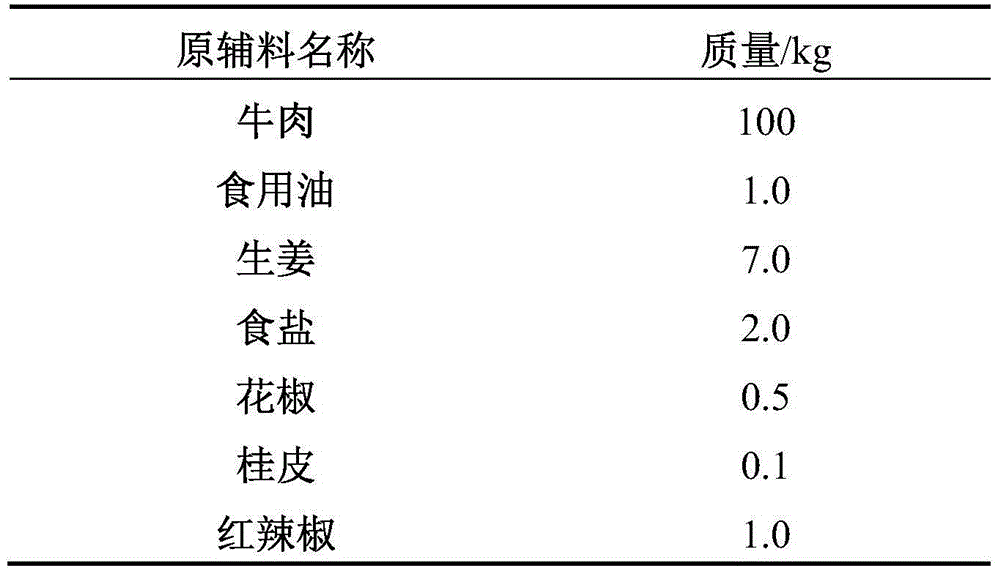

[0062] 1. Raw and auxiliary materials

[0063] Raw material: Chunk beef, select the rib meat part of adult beef

[0064] Accessories: cooking oil, ginger, salt, pepper, chili

[0065] Table 1 Ratio of raw and auxiliary materials

[0066]

[0067] 2. Technological process

[0068] Raw meat→trimming→stir frying with spices→stir frying of meat pieces→drying water→changing pots for marinating→seasoning→drying→packing→labeling and boxing→inspection and warehousing

[0069] 2. Process points

[0070] 1. Raw material trimming

[0071] Choose fat and thin fresh beef or thawed frozen beef, wash away the blood and dirt, cut into 8-10 cm wide meat strips along the direction of muscle fibers, and then cut into 10-15 cm long perpendicular to the fiber direction spare pieces of meat;

[0072] 2. Stir fry with spices

[0073] Heat the frying pan, put in the cooking oil according to the ratio l...

Embodiment 2

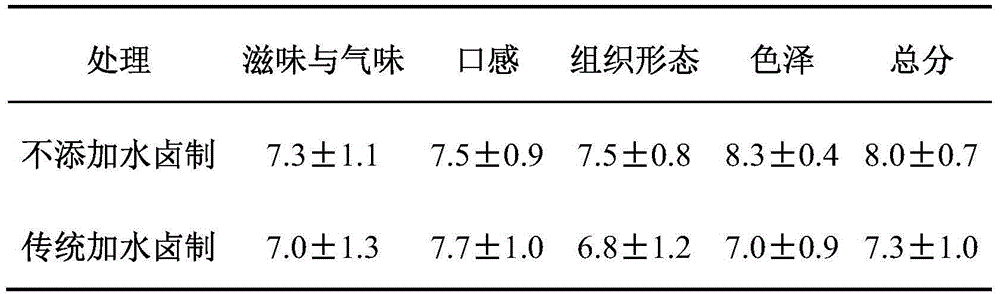

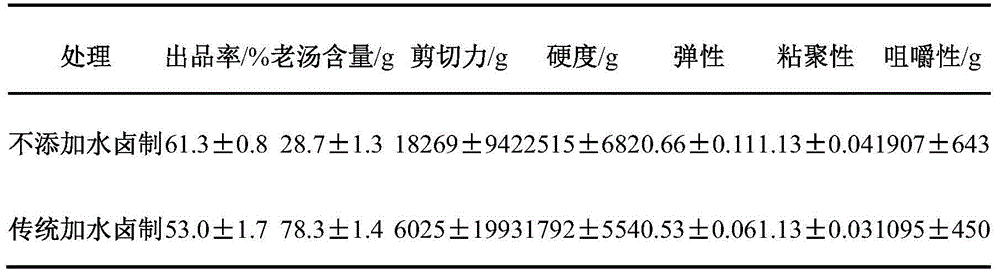

[0088] Embodiment 2 Verification test of a novel method for making stewed meat without adding water

[0089] 1. The traditional method of making stewed meat with exogenous moisture added

[0090] Beef, the flank meat of an adult beef

[0091] This embodiment is divided into an experimental group and a control group, and the experimental group adopts the method steps described in the implementation case 1 to make stewed meat; the control group makes a material bag containing cinnamon bark, Chinese prickly ash, and capsicum according to the formula of the raw materials of the implementation case 1, Add exogenous water equal to the weight of beef and put it into the marinated pot to cook the material bag, then put the beef block described in the step 1 of the implementation case 1 into the marinated pot for 2 and a half hours, and add the implementation case 1 Table 1 in 2 hours table salt listed. After marinating, let it dry. Carry out sensory evaluation on the finished produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com