Production method of pvc disposable gloves

A production method and one-off technology, applied in protective clothing and other directions, can solve the problems of harsh working environment of operators, have not been thoroughly renovated, and high workshop temperature, and achieve the goal of enhancing environmental protection value, high environmental protection value, and reducing pollution emissions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

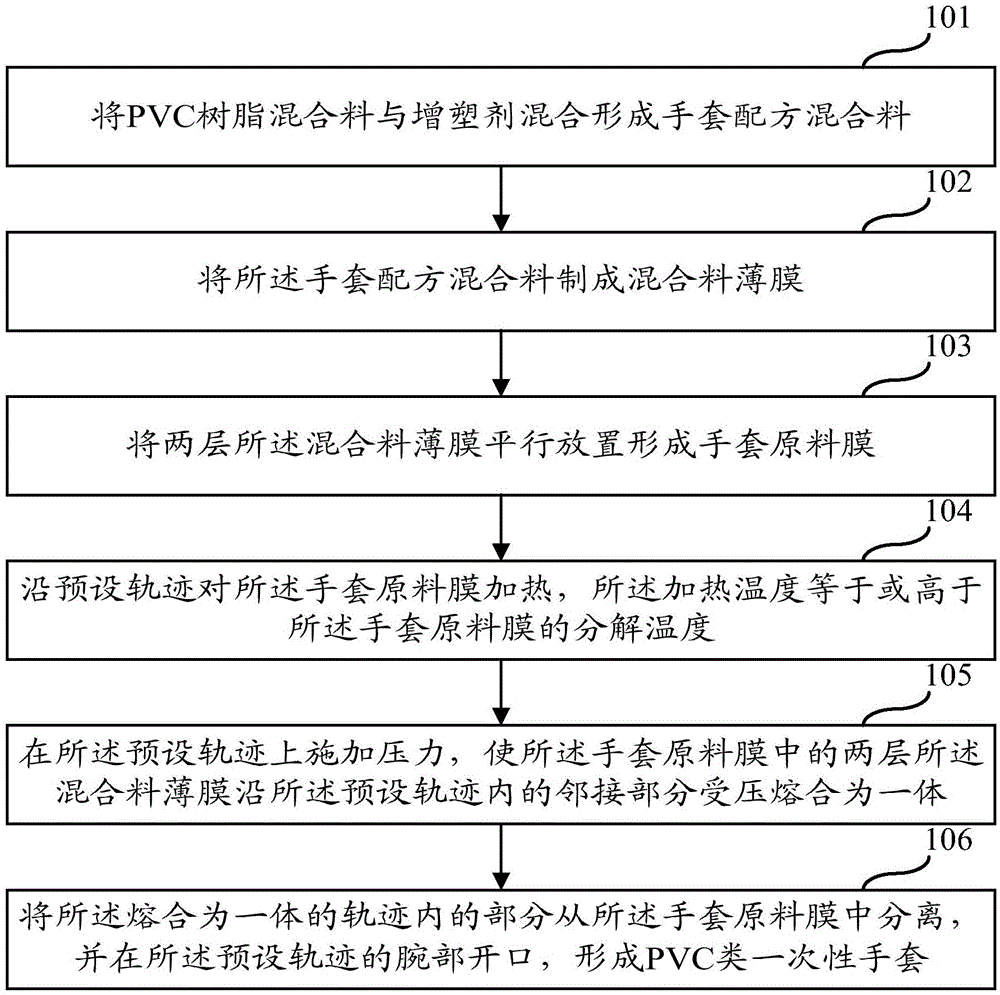

[0059] The production method of the PVC class disposable gloves of the embodiment of the present invention, as figure 1 shown, including the following steps:

[0060] Step 101, mixing the PVC resin mixture with a plasticizer to form a glove formula mixture;

[0061] Step 102, making the glove formula mixture into a mixture film;

[0062] Step 103, placing two layers of the mixture film in parallel to form a glove raw material film;

[0063] Step 104, heating the raw glove film along a preset track, the heating temperature being equal to or higher than the decomposition temperature of the raw glove film;

[0064] Step 105, applying pressure on the preset track, so that the two layers of the compound film in the glove raw material film are fused together under pressure along the adjacent parts in the preset track;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com