Drawing device and method of nuclear power super pipeline nozzles

A super pipe and nozzle technology, which is applied in the field of nuclear power super pipe nozzle drawing devices, can solve the problems of high labor intensity of operators, limited use of products, low work efficiency, etc., to improve working conditions, reduce labor intensity, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

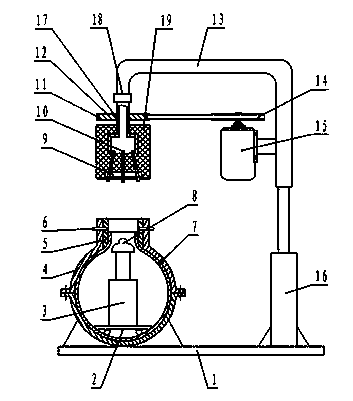

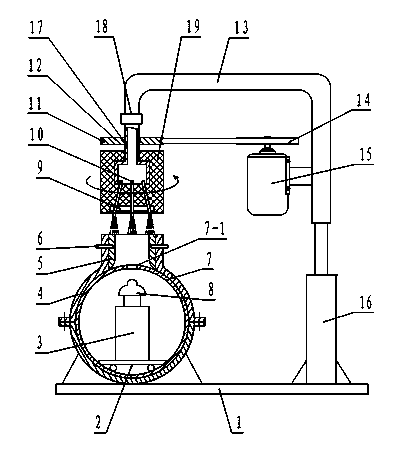

[0024] Referring to Fig. 1, the present invention comprises base platform 1, drawing mold, rotary flame heating mechanism, rotary drive mechanism, lifting arm 13, lifting oil cylinder 16 and PLC system, described base platform 1 is fixed on the level ground, in A drawing mold is installed on one side of the base platform 1, and a lifting cylinder 16 is fixedly installed on the other side. The telescopic arm of the lifting cylinder 16 is connected to the lifting arm 13, and the lifting arm 13 is an inverted "L" structure. Its end is located above the drawing die, and a rotary flame heating mechanism is installed at the end of the lifting arm 13; the rotary flame heating mechanism includes a rotating nozzle seat 17, a nozzle 10 and a nozzle cooling water jacket 9, and the outer surface of the rotating nozzle seat 17 is An insulating layer 19 is provided, and the rotating nozzle seat 17 is a cavity structure, and its internal cavity communicates with the gas pipeline and the oxyge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com