Rolling mill stand boring machine

A rolling mill stand and boring machine technology, applied in the field of boring machines, can solve the problems of strict relative position requirements, high hole machining accuracy, low machining efficiency, etc., to avoid low position accuracy or out-of-tolerance, high accuracy, and improve machining efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

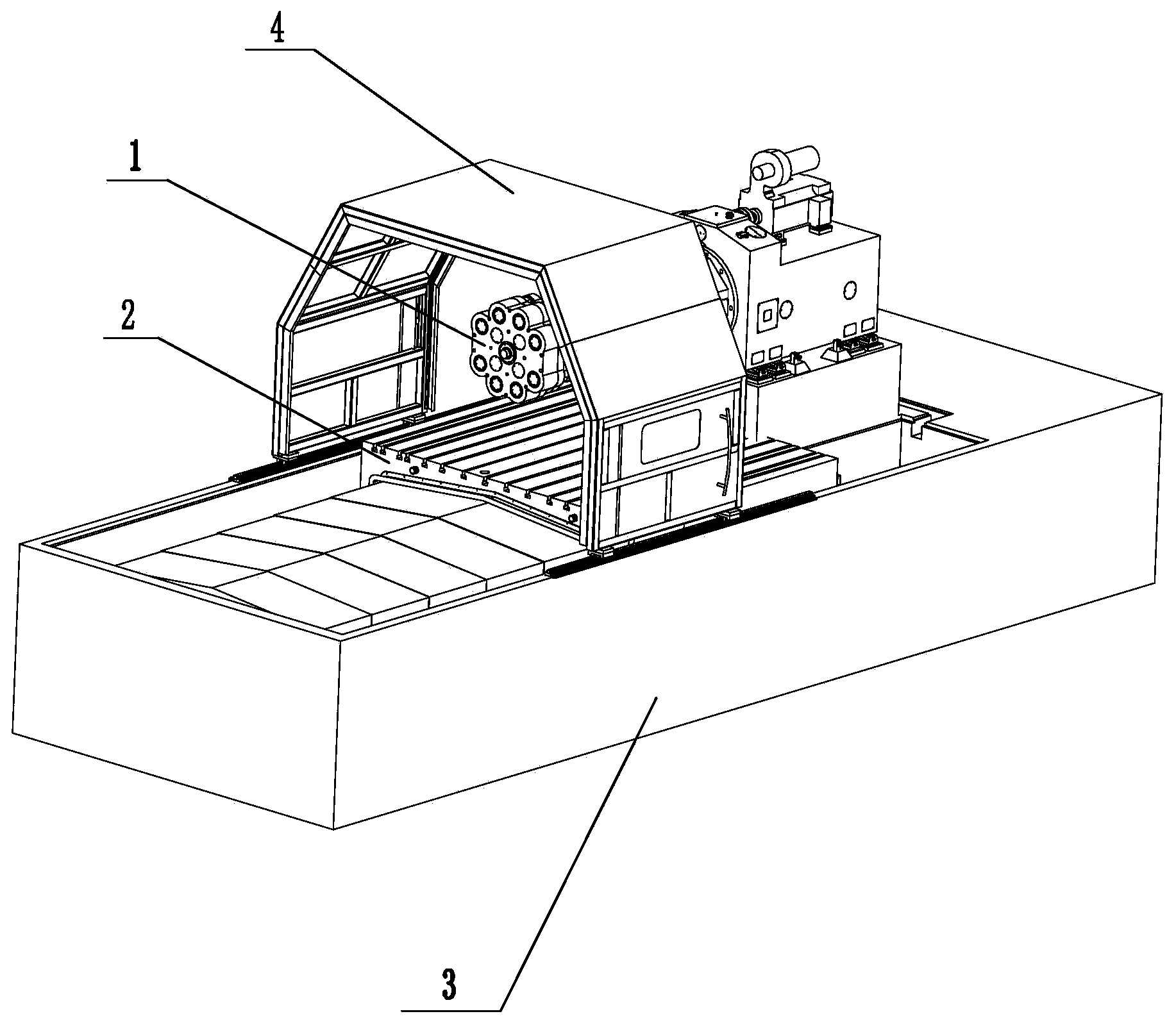

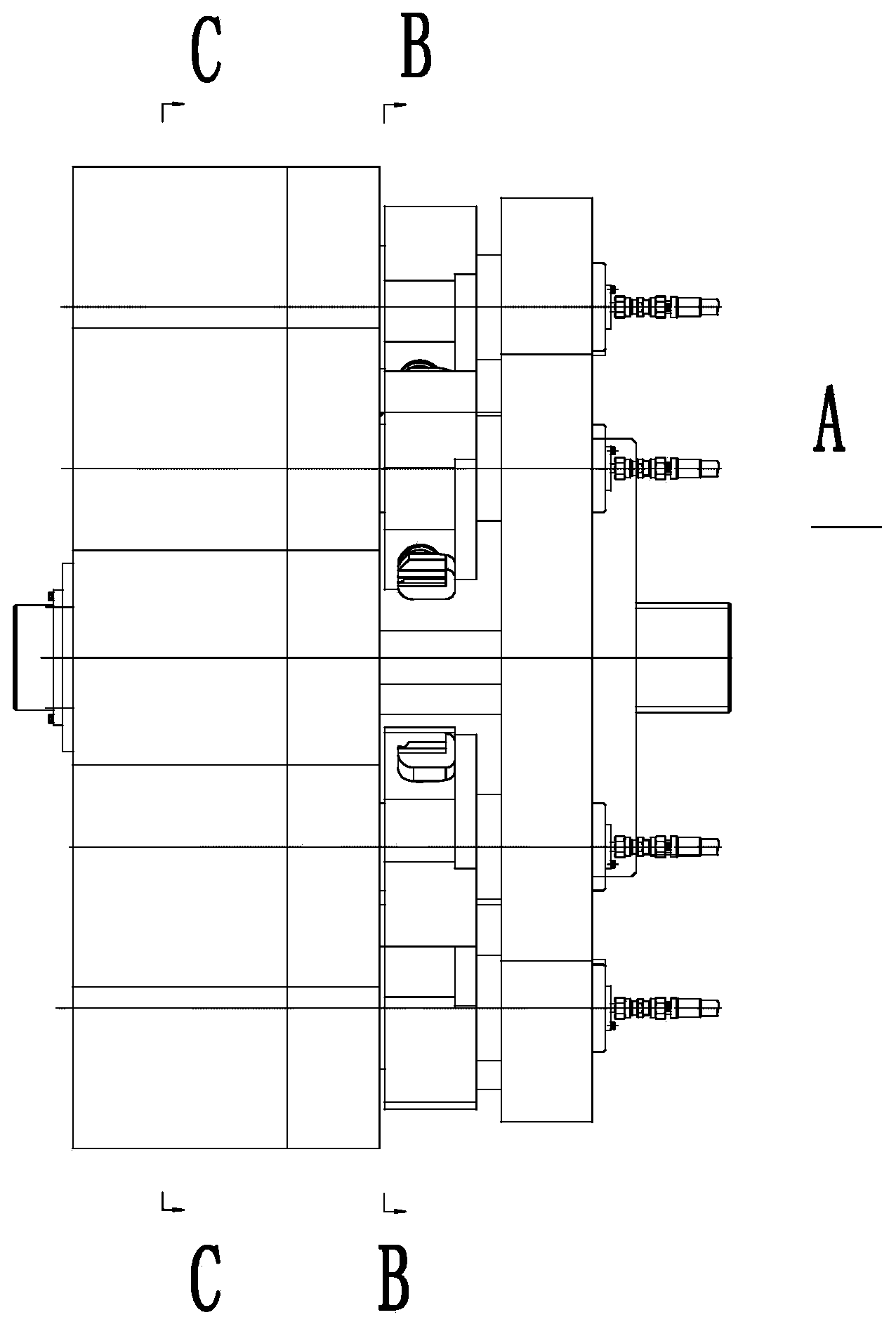

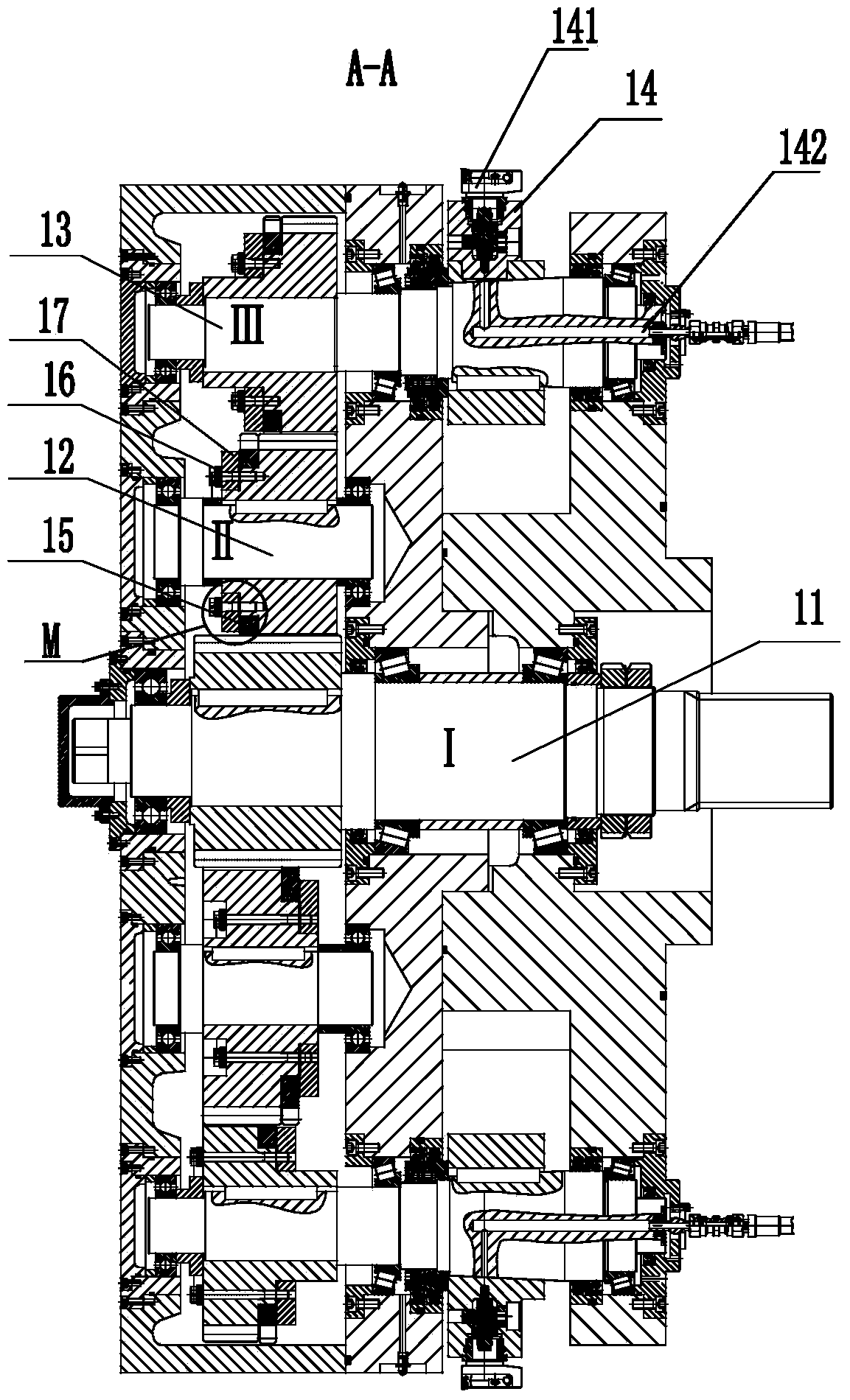

[0035] As shown in the figure, a rolling mill rack boring machine disclosed by the present invention includes a boring head 14 mechanism 1, a worktable 2, and a bed 3. The worktable 2 can move on the bed 3, and the bed 3 A protective cover 4 is provided, and the boring head 14 mechanism 1 is fixed on the bed 3. The boring head 14 mechanism 1 includes eight boring heads 14, III axis 13, II axis 12, I axis 11, and the boring head 14 is set There is a quick-change boring tool 141 produced by Sweden SANDVIK (Sandvik); the boring heads 14 are arranged in the base and correspond to the plum blossom holes of the rolling mill stand one by one, and the boring heads 14 are respectively arranged on a III shaft 13, each Two III shafts 13 are linked with one II shaft 12 through gears, four II shafts 12 are linked with I shaft 11 through gears, and III shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com