Secondary screening printing anti-counterfeiting method

A technology of printing machine and screen line number, which is applied in the anti-counterfeiting field of secondary screen printing, which can solve the problems of high anti-counterfeiting cost, easy to be copied, and unsatisfactory anti-counterfeiting effect, and achieve the effect of low anti-counterfeiting cost and good anti-counterfeiting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing:

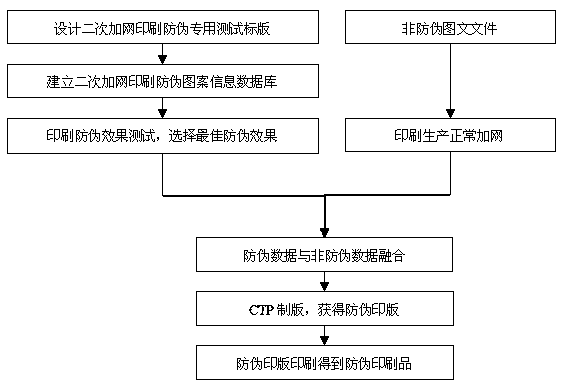

[0029] Such as figure 1 As shown, the second screen printing anti-counterfeiting method specifically includes the following steps:

[0030] Step 1. The establishment of the information database of anti-counterfeiting patterns for secondary screen printing

[0031] 1-1. According to the characteristics of printing paper, ink characteristics, printing machine working conditions and product characteristics of the printing enterprise, determine the screening parameters during pre-press CTP plate making. The screening parameters include dot type, screen line number and dot angle;

[0032] 1-2. Design the second screen printing anti-counterfeiting special test standard plate

[0033] Design special color blocks with various CMYK dot percentages to form special anti-counterfeiting test plates for secondary screen printing; the CMYK dot percentages include 20-level dots from 5%, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com