Synthesis method of IM-5 molecular sieve

A synthesis method and molecular sieve technology, applied in the direction of crystalline aluminosilicate zeolite and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The present invention provides a method for synthesizing IM-5 molecular sieve, which is characterized in that the method includes:

[0028] (1) Under stirring conditions, the mixed solution containing the aluminum source is contacted with the silicon source to form a colloid, and the mixed solution containing the aluminum source is an aqueous solution containing an inorganic base, a mineralizer, an aluminum source and a template agent;

[0029] (2) Under the conditions of the crystallization reaction, hydrothermally crystallize the colloid;

[0030] The inorganic base, the mineralizer, the aluminum source, the template, the silicon source, and water are charged so that the composition of the colloid is SiO 2 : Al 2 O 3 : M 2 O: MX: SDA: H 2 O=10: (0.1-1): (1-10): (0.1-5): (0.1-4): (50-500); the silicon source is SiO 2 The aluminum source is Al 2 O 3 Calculated, the inorganic base is M 2 In terms of O, MX is the mineralizer, SDA is the template agent; the mineralizer is a metal ...

preparation example 1

[0057] According to the literature (Synthesis, characterization and catalytic properties of IM-5 and NU-88 molecular sieves; Synthesis, characterization, and catalytic properties of zeolites IM-5 and NU-88. Journal of Catalysis 2003:215 151~170) -5 molecular sieve.

[0058] Combine 10.19g 1,5-bis(N-methylpyrrolidine)pentane aqueous solution, 2.92g NaOH, 1.1g Al(NO 3 ) 3 ·9H 2 Dissolve O in an appropriate amount of deionized water, mix well, add 6.19g white carbon black under stirring conditions to make a milky white colloid, the molar composition of the reaction mixture is: SiO 2 : Al 2 O 3 : Na 2 O: R: H 2 O=10:0.167:3.65:1.5:400 (where R is 1,5-bis(N-methylpyrrolidine)pentane). The resulting mixture was stirred at room temperature for 24 hours, and the prepared colloid was transferred to a 50 mL polytetrafluoroethylene lined crystallization kettle, and rotated at 160°C for 14 days after crystallization, and the rotation speed was 100 rpm. The crystallization reaction is stopped...

Embodiment 1

[0061] This example is used to illustrate the synthesis method of IM-5 molecular sieve of the present invention.

[0062] 0.67gAlCl 3 , 4.53g NaOH, 1.71g NaCl, and 22.68g SDA are dissolved in an appropriate amount of deionized water and mixed uniformly. Under stirring conditions, 40g silica sol is slowly added dropwise to form a milky white colloid, and stirring is continued for 2h. The molar composition of the colloid is: SiO 2 : Al 2 O 3 : Na 2 O: NaCl: SDA: H 2 O=10:0.25:2.83:1:1.67:400.

[0063] Transfer the prepared colloid to a 100mL polytetrafluoroethylene lined autoclave. After rotating and crystallizing at 175℃ for 10 days, stop the crystallization reaction. After washing and filtering, the product is dried at 80℃ overnight to obtain molecular sieve. Original powder A1.

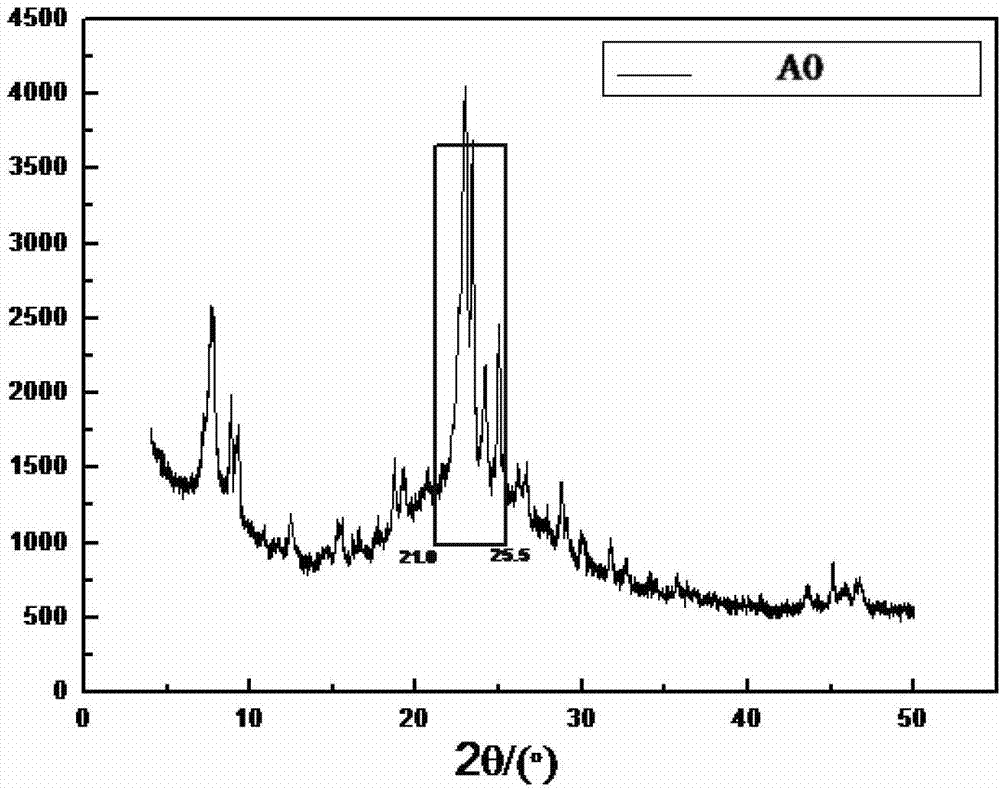

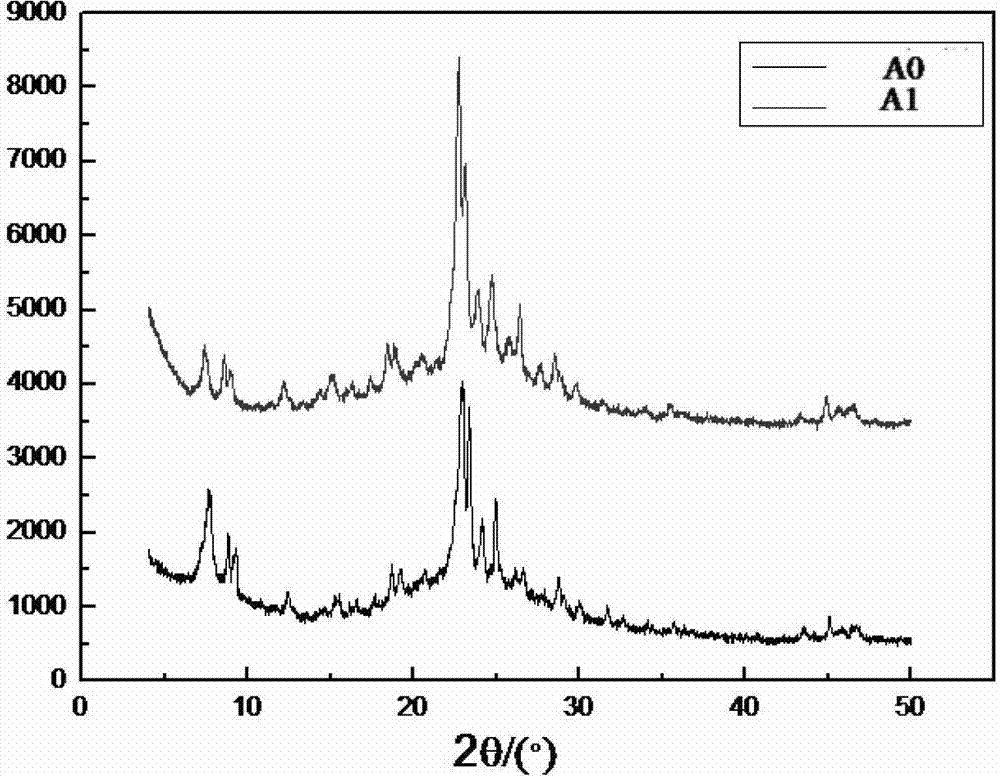

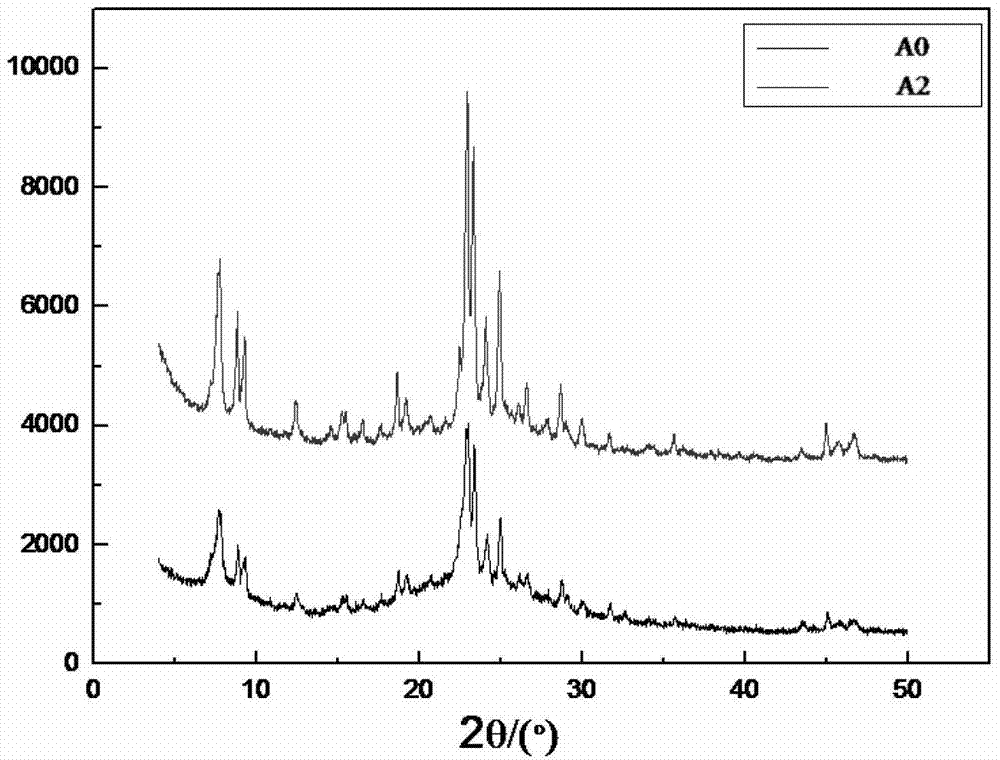

[0064] The XRD measurement results of the original molecular sieve powder A1 were compared with the XRD spectra of IM-5 molecular sieve published in the document "Determining the pore structure of IM-5 mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com