A kind of soft polyurethane foam for car seat cushion

A polyurethane foam, polyester block technology, applied in the field of auto parts, can solve the problems of deterioration of vibration performance, difficulty in meeting vibration performance, soft touch, poor air permeability, etc., and achieves the effect of low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The content of the present invention will be described in detail below through specific embodiments.

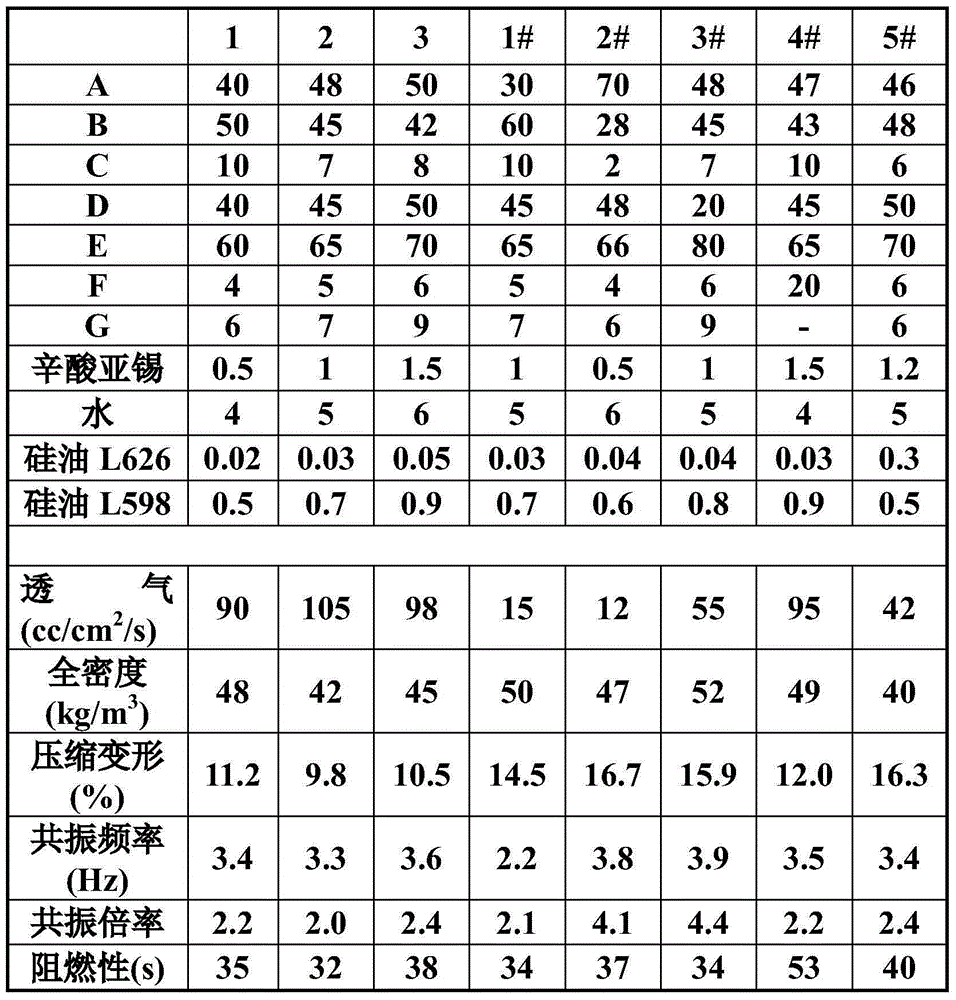

[0025] Prepare the raw materials according to the composition ratio of the foaming stock solution described in Table 1, and then gradually add the raw materials to the mixing container according to the order of polyol composition, catalyst, foam stabilizer, water, flame retardant, and polyisocyanate. In the process, while adding materials, stir evenly, maintain the temperature of the well-mixed foaming stock solution at 30°C; preheat the temperature of the foaming mold to 50°C, and then inject the evenly mixed foaming stock solution into the foaming mold under atmospheric pressure After the injection is completed, the foaming and curing will begin immediately, and the pressure will be released immediately after foaming 90s to reduce the pressure in the cavity by 0.1MPa; after the foaming, the foamed material will be placed for 24h to obtain The final polyurethane foam mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com