Floating hollow polyester fiber mooring rope and manufacturing method thereof

A technology of polyester fiber and production method, which is applied in the field of fiber rope, can solve the problems of polyester and polyamide ropes with high proportion, polypropylene fiber is not resistant to ultraviolet rays, and biological adhesion, etc., and achieves excellent wear resistance, antibacterial and antifouling Good effect and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

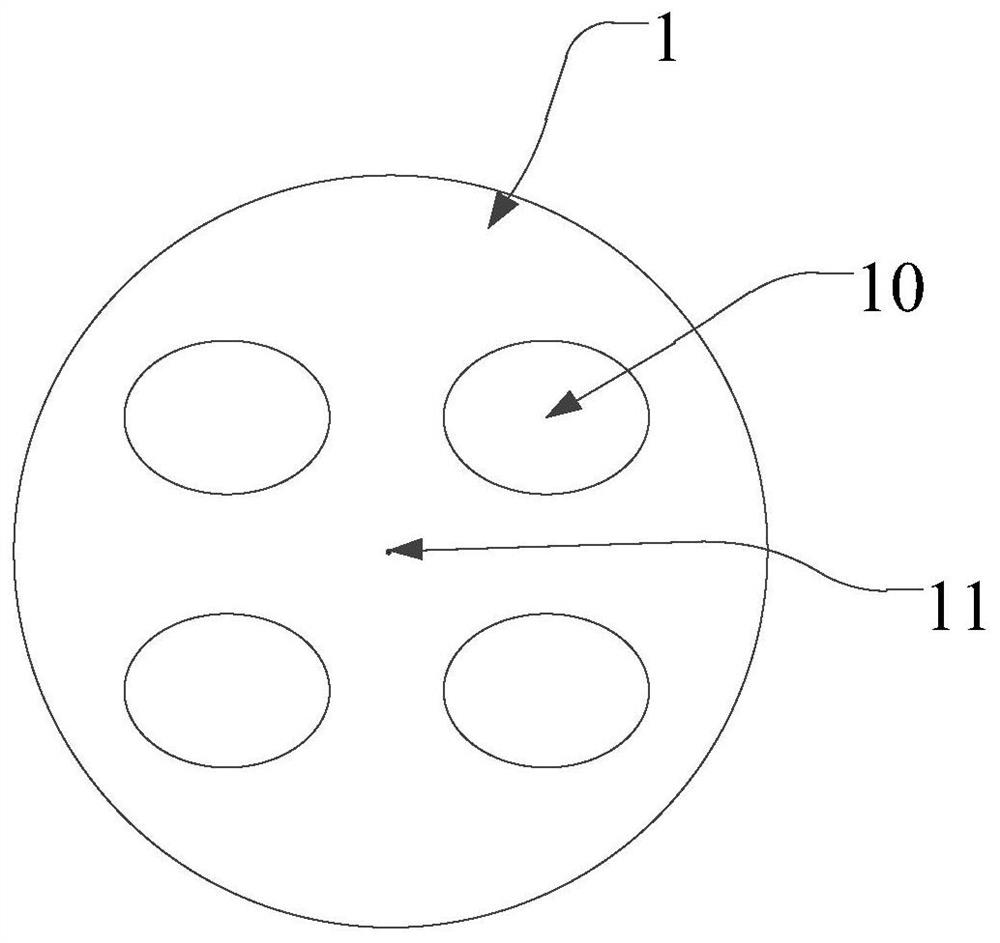

[0052] Three-strand hollow polyester fiber floating mooring twisted rope

[0053] The production process of the three-strand hollow polyester fiber floating mooring twisted rope includes:

[0054] (1) Polyester chips, ethylene-vinyl acetate copolymer, antioxidant 1010, co-antioxidant DLTP and nano silver-loaded cuprous oxide antibacterial agent are granulated in a granulator to obtain polyester modified composites; Among them, the intrinsic viscosity of polyester chips is 0.90dl / g, the content of terminal carboxylic acid is 25mol / t, and the content of diethylene glycol is less than 1.2%; the quality of ethylene-vinyl acetate copolymer is 1.2‰ of that of polyester chips, and the The temperature is less than -60°C; the quality of antioxidant 1010 is 0.1‰ of the quality of polyester chips, the initial melting point is not less than 110°C, the volatile content is not more than 0.5%, and the ash content is not more than 0.1%; the quality of auxiliary antioxidant DLTP is 0.5‰ of th...

Embodiment 2

[0062] Eight-strand hollow polyester fiber floating mooring single braided rope

[0063] The production process of the eight-strand hollow polyester fiber floating mooring single braided rope includes:

[0064] (1) Polyester chips, ethylene-vinyl acetate copolymer, antioxidant 1010, co-antioxidant DLTP and nano silver-loaded cuprous oxide antibacterial agent are granulated in a granulator to obtain polyester modified composites; Among them, the intrinsic viscosity of polyester chips is 1.05dl / g, the content of terminal carboxylic acid is 25mol / t, and the content of diethylene glycol is less than 1.2%; the quality of ethylene-vinyl acetate copolymer is 3.5‰ of that of polyester chips, and the The temperature is less than -60°C; the quality of antioxidant 1010 is 2.0‰ of the quality of polyester chips, the initial melting point is not less than 110°C, the volatile content is not more than 0.5%, and the ash content is not more than 0.1%; the quality of auxiliary antioxidant DLTP ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com