High-performance high-hardness mining machinery gear ring forge piece and manufacturing method

A manufacturing method and high hardness technology, applied in the field of ring gear ring forging manufacturing, can solve the problems of key technology blockade, difficult to refer to materials, etc., to achieve the effect of optimizing the process, shortening the delivery time, and improving the comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A high-performance and high-hardness mining machinery ring gear ring forging, in terms of weight percentage, its raw materials include the following components:

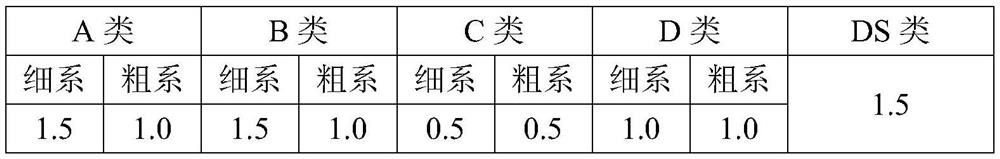

[0054] C: 0.38%; Si: 0.36%; Mn: 0.67%; Cr: 1.10%; Mo: 0.25%; V: 0.1%; P: 0.01%; S: 0.001%; , Si, Mn, Cr, and Mo are controlled according to the middle and upper limits, P and S are controlled according to the middle and lower limits, and non-metallic inclusions are controlled according to Table 1.

[0055] Table 1

[0056]

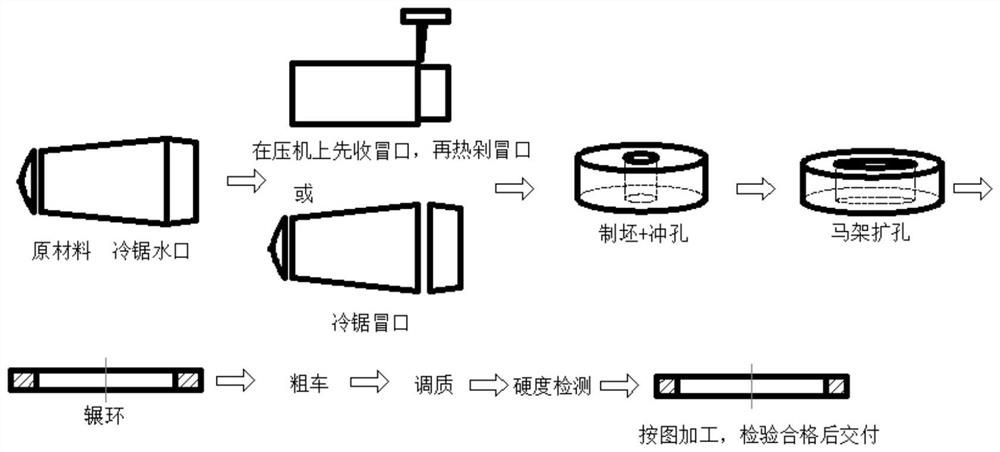

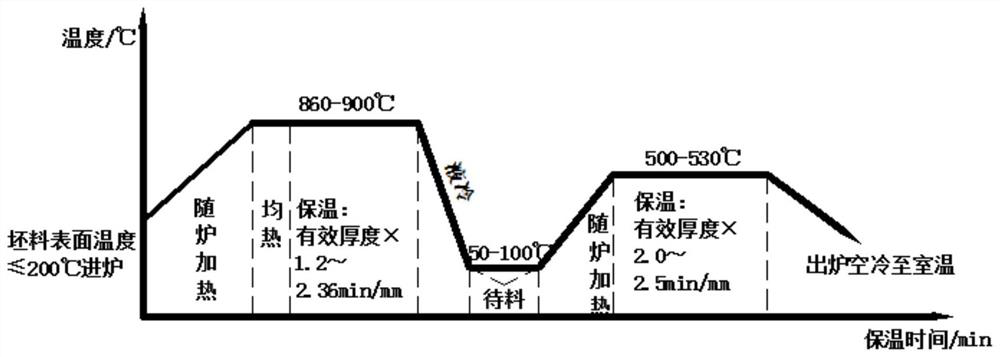

[0057] Such as Figure 1-2 Shown, a kind of manufacturing method of high-performance high-hardness mine machinery ring gear ring forging, comprises the following steps:

[0058] 1) Cutting: The raw material is cut by cold sawing nozzle, and after removing impurities, the riser is first collected on the press and then heated;

[0059] 2) Forging billet making and punching: three upsetting and two drawing are used when opening the billet, the upsetting ratio of each step is controlled ...

Embodiment 2

[0072] The difference between this embodiment and Embodiment 1 is that the raw materials of the high-performance and high-hardness mining machinery ring gear ring forging in this embodiment include the following components in terms of weight percentage:

[0073] C: 0.39%; Si: 0.37%; Mn: 0.70%; Cr: 1.10%; Mo: 0.25%; V: 0.05%; P: 0.005%; S: 0.0009%; , Si, Mn, Cr, and Mo are controlled according to the middle and upper limits, P and S are controlled according to the middle and lower limits, and non-metallic inclusions are controlled according to Table 1.

[0074] Table 1

[0075]

[0076] The rest are the same as embodiment 1.

Embodiment 3

[0078] The difference between this embodiment and Embodiment 1 is that the raw materials of the high-performance and high-hardness mining machinery ring gear ring forging in this embodiment include the following components in terms of weight percentage:

[0079] C: 0.40%; Si: 0.3%; Mn: 0.68%; Cr: 1.08%; Mo: 0.24%; V: 0.09%; P: 0.005%; S: 0.002%; , Si, Mn, Cr, and Mo are controlled according to the middle and upper limits, P and S are controlled according to the middle and lower limits, and non-metallic inclusions are controlled according to Table 1.

[0080] Table 1

[0081]

[0082] The rest are the same as embodiment 1.

[0083] Parts that are not specifically described can be used in the prior art, and will not be described in detail here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com