Residue-free sesame utilization technology

A technology of sesame and craftsmanship, applied in the field of sesame non-residue utilization technology, can solve the problems of reducing the utilization rate of sesame, residue, waste of resources, etc., and achieve the effect of increasing use value, reducing enterprise cost, and increasing food flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

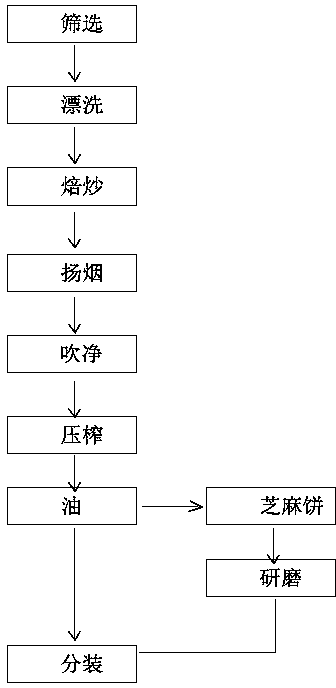

[0021] Embodiment one: A non-residue utilization process of sesame, which uses common sesame, comprises the following steps:

[0022] a) filter : Select 1000kg of new sesame seeds that are ripe and plump, moderately dry and wet, and use a vibrating screen and a destoner to remove various impurities to obtain 900kg of sesame seeds;

[0023] b) rinsing: Rinse with a seed washing machine to remove floating impurities and precipitated sediment to 850kg, and then soften it to make the phospholipids in sesame absorb water and expand to accelerate protein denaturation;

[0024] c) Roasting: When frying sesame seeds, use medium temperature heating and frying, the temperature is controlled at 160±10°C, and roast until golden yellow;

[0025] d) smoke : Remove the smoke from the roasted sesame and retain the original aroma of the sesame;

[0026] e) blow off : remove the loose matter in the roasted sesame;

[0027] f) press : Hydraulic oil press is used to press, the pres...

Embodiment 2

[0032] Embodiment two: A non-residue utilization process of sesame, which uses high-quality sesame, comprises the following steps:

[0033] a) filter : Select 1000kg of new sesame seeds that are mature, plump, and moderately dry and wet, and use a vibrating screen and a destoner to remove various impurities to obtain 950kg of sesame seeds;

[0034] b) rinsing: Rinse with a seed washing machine to remove floating impurities and precipitated sediment to 900kg, and then soften it to make the phospholipids in sesame absorb water and expand to accelerate protein denaturation;

[0035] c) Roasting: When frying sesame seeds, use medium temperature heating and frying, the temperature is controlled at 160±10°C, and roast until golden yellow;

[0036] d) smoke : Remove the smoke from the roasted sesame and retain the original aroma of the sesame;

[0037] e) blow off : remove the loose matter in the roasted sesame;

[0038] f) press : Hydraulic oil press is used to press,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com