Annular steel wire rope lamination rubber compound seismic reduction and isolation bearer

A technology of laminated rubber and rubber bearing is applied in the seismic field of nuclear power plants, bridges, housing construction and mechanical engineering. , Broad market prospects, easy reset effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

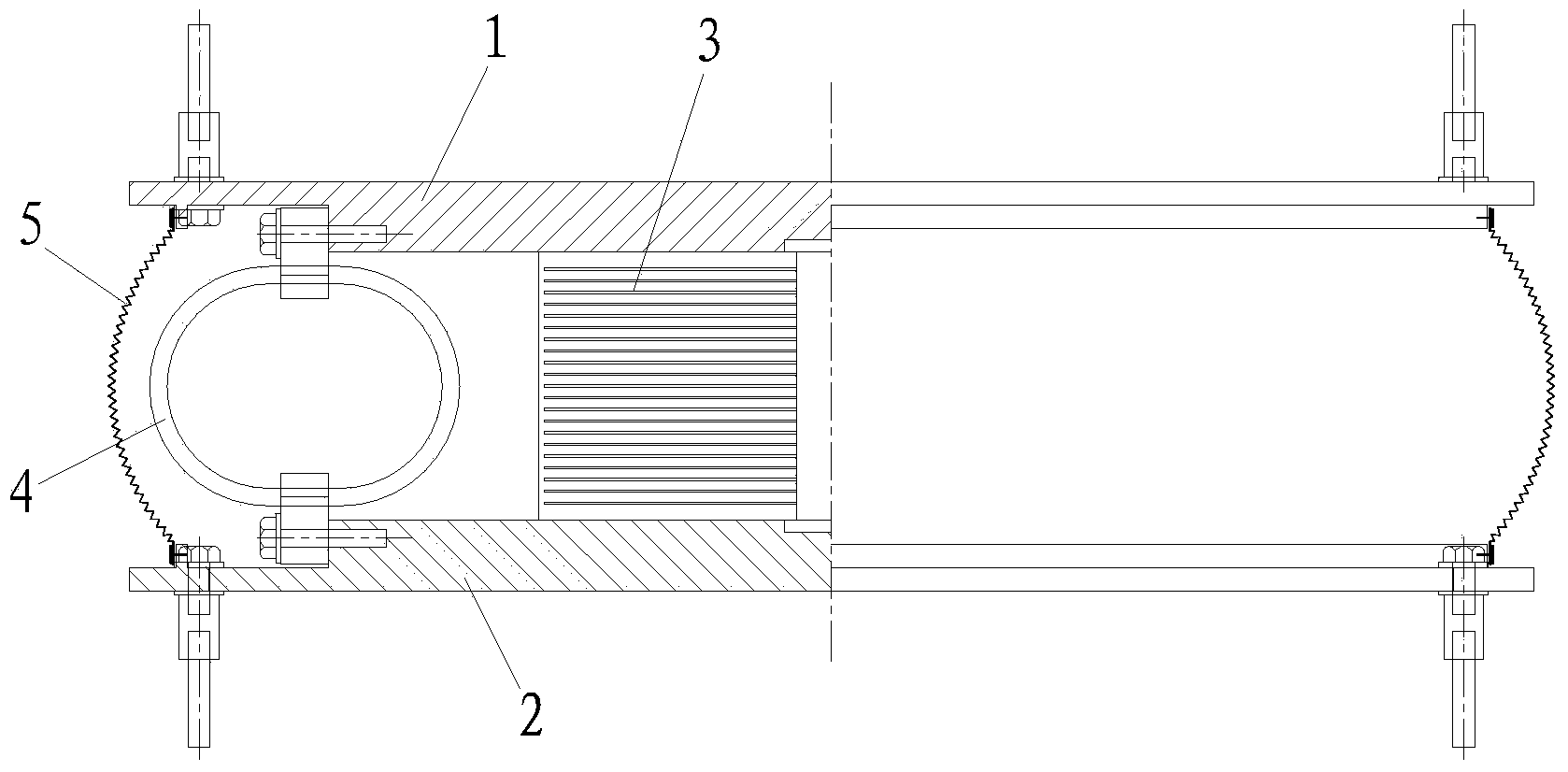

[0030] Such as figure 1 As shown, the present invention includes an upper support plate 1 and a lower support plate 2, and a rubber support 3, a damper and a dust cover 5 are arranged between the upper support plate 1 and the lower support plate 2, and the rubber support 3 is a stacked Layer rubber bearing or lead core rubber bearing, the damper is a wire rope damper 4, and the wire rope damper 4 is arranged in a ring shape on the periphery of the laminated rubber bearing or lead core rubber bearing, and the dust cover 5. The upper and lower ends are respectively connected with the upper support plate 1 and the lower support plate 2 to cover the wire rope damper 4.

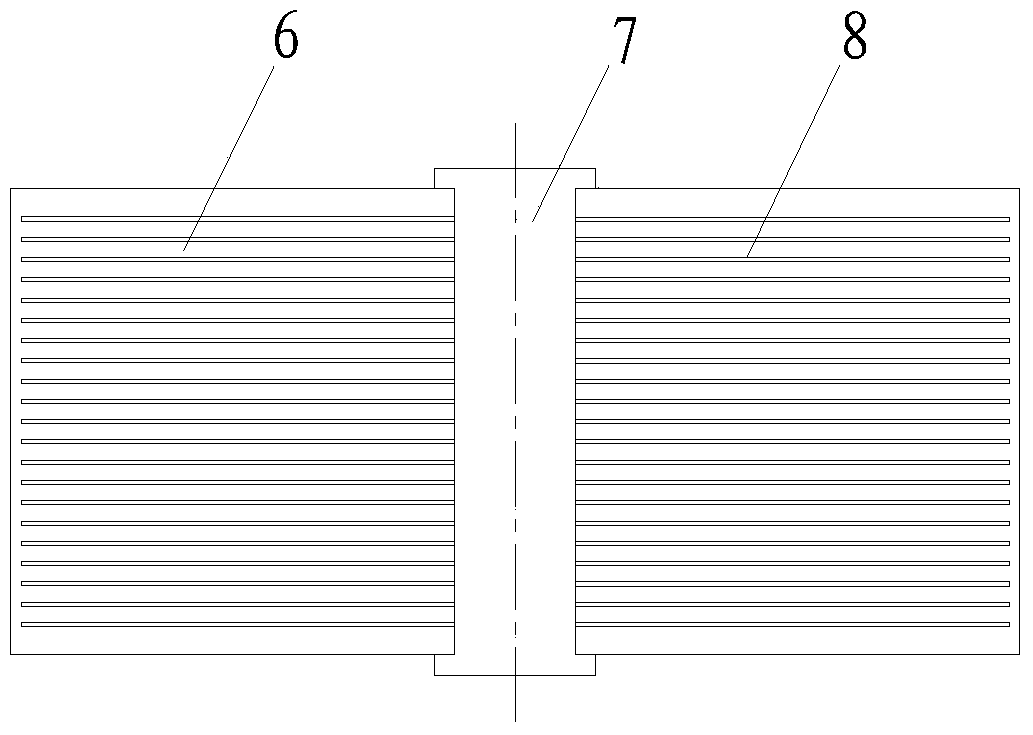

[0031] The laminated rubber bearing is formed by laminating one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com