Building formwork cast in engineering plastic

A technology of engineering plastics and casting molding, which is applied in the direction of construction, building structure, formwork/formwork components, etc. It can solve the problems of shrinking steel formwork service life, uneven cement components, and difficult cleaning of steel formwork, so as to reduce corrosion. , reduce weight, facilitate transportation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

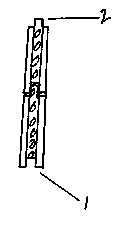

[0006] Detailed ways Accompanying drawing shows a kind of engineering plastics casting molding building formwork of the present invention

[0007] Since the joints between the formworks use the concave 1 convex 2 type, the bottom surface of the joint has a supporting protruding plane, which prevents the cement slurry from flowing out of the gap and improves the surface quality of the cast product. The cement is easier to remove from the formwork due to the use of PPR material. At the same time, it reduces the corrosion of cement to the formwork and improves the service life of the formwork. Due to the use of engineering plastics, the production cost is reduced, the weight of the formwork is reduced, and the transportation and use are convenient. The popularization and application of this technology will be a revolution in the history of building construction, and its significance is very great.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com