Device for heating preheat evaporation area of rectangular wire enameling machine oven by utilization of exhaust gas waste heat

A heating device and evaporation zone technology, which is applied in the field of heating devices using waste gas waste heat in the preheating evaporation zone of a middle rectangular wire enameling machine, can solve the problems of increasing the cost of electricity consumption of rectangular enameled wires, and achieve the goal of reducing power consumption and reducing exhaust gas emissions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

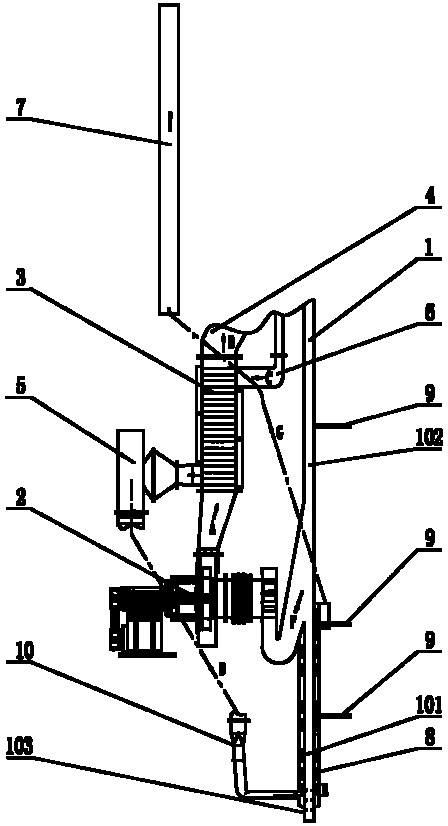

[0014] See figure 1 The heating device described in this embodiment includes a furnace 1, the furnace 1 includes a lower preheating evaporation zone 101 and an upper solidification zone 102, the lower preheating evaporation zone 101 and the upper curing zone 102 are connected, and the bottom of the preheating evaporation zone 101 is the furnace Inlet 103, one side of the lower part of the curing area 102 is connected to the inlet pipeline of the main circulation fan 2, the outlet of the main circulation fan 2 is connected to the heat exchanger 3 pipeline, and the other end of the heat exchanger 3 is connected to the circulation cavity 4, and the circulation cavity 4 The top outlet of the exhaust fan 5 is connected to the top tuyere of the furnace 1, the suction port of the exhaust fan 5 is connected to the heat exchanger 3, the outlet of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com