Charging connector and wire harness assembly for electric vehicle and hybrid electric vehicle

A hybrid electric vehicle and charging connector technology, which is applied in electric vehicle charging technology, electric vehicles, connection and other directions, can solve the problems of high rigidity insertion accuracy, poor shielding effect, and insertion displacement, etc. The effect of plugging life, avoiding interference, and reducing the magnitude of temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

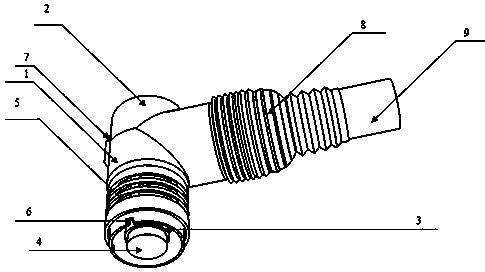

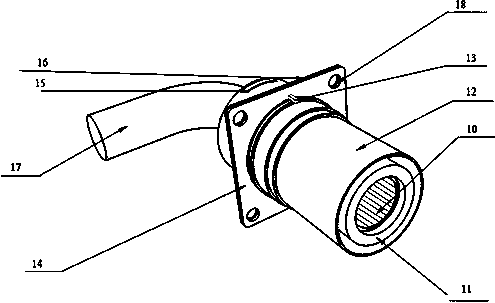

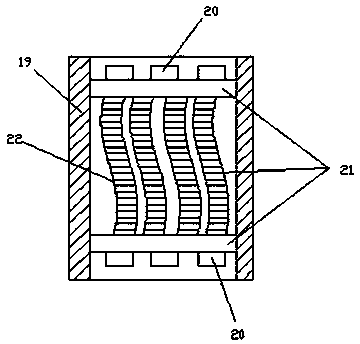

[0030] Such as figure 1 As shown, a charging connector and wire harness assembly for electric vehicles and hybrid vehicles includes a plug part and a socket part, and the plug part includes a plug front cover 1, a plug rear cover 2, a metal ferrule 3, a rubber plug Core 4, plug support base, fastening screw 7, rubber sheath 8, power cable 9 and cable ferrule 23; the metal ferrule 3 is cylindrical, and the metal ferrule 3 is provided with a cylindrical Rubber ferrule 4, the outer diameter of the rubber ferrule 4 is consistent with the inner diameter of the metal ferrule 3, the length of the rubber ferrule 4 is greater than the length of the metal ferrule 3, and the metal ferrule 3 passes through the plug The support base is connected to one end of the power cable 9, the metal ferrule 3 and the power cable 9 are perpendicular to ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com