Preparation method and magnetic activated carbon prepared by same

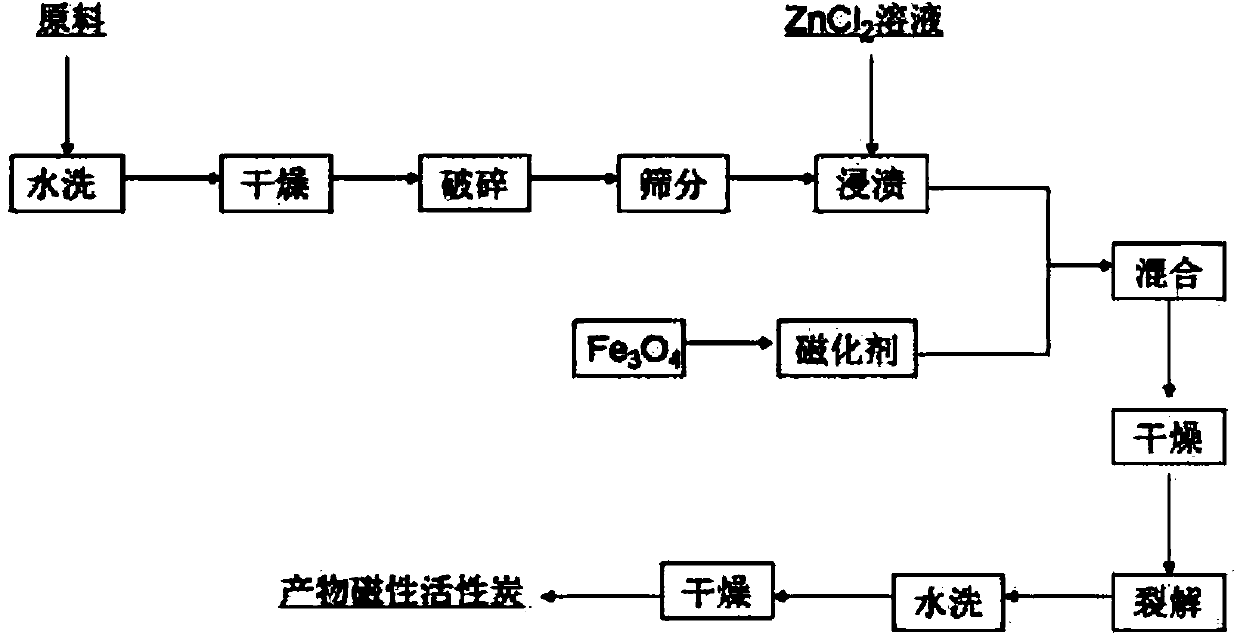

A technology of magnetic activated carbon and waste biomass, which is applied in the preparation of magnetic activated carbon and the field of magnetic activated carbon, which can solve the problems of complex production process and the inability to solve the stability and adsorption of magnetic activated carbon at the same time, and achieve simple and clean preparation process Environmental protection and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Weigh 10g of zinc chloride, add 40mL of water and 2mL of concentrated hydrochloric acid to prevent hydrolysis of zinc chloride. Weigh 5g of Chinese fir sawdust, immerse the Chinese fir sawdust in zinc chloride solution for 24h, wherein the mass ratio of sawdust to zinc chloride is 1:2, weigh 0.3g Fe 3 o 4 , and 0.3g lauric acid, Fe 3 o 4 Add 15mL of water with lauric acid, add 2mL of 5mol / L NaOH solution, and bathe in water at 90°C for 0.5h; add dilute hydrochloric acid to it to pH=4~5, and collect Fe 3 o 4 The particles were washed with water until pH = 7, then 0.6g sodium dodecylsulfonate and 20mL water were added, and the magnetic agent was prepared in a water bath at 60°C for 1 hour. Mix the impregnated fir chips with the magnetizer, stir evenly, and dry. The dried sample was weighed and placed in a reaction furnace, protected by argon, cracked at a final temperature of 450°C, the heating rate was 5°C / min, and the magnetic activated carbon was prepared under th...

Embodiment 2

[0050] Weigh 10g of zinc chloride, add 40mL of water and 2mL of concentrated hydrochloric acid to prevent hydrolysis of zinc chloride. Weigh 5g of Chinese fir sawdust, immerse the Chinese fir sawdust in zinc chloride solution for 24h, wherein the mass ratio of sawdust to zinc chloride is 1:2, weigh 0.5g Fe 3 o 4 , and 1.0g lauric acid, Fe 3 o 4 Add 15mL of water with lauric acid, add 2mL of 5mol / L NaOH solution, and bathe in water at 90°C for 0.5h; add dilute hydrochloric acid to it to pH=4~5, and collect Fe 3 o 4 The particles were washed with water until pH = 7, then 1.0g of sodium dodecylsulfonate and 20mL of water were added, and the magnetic agent was prepared in a water bath at 60°C for 1 hour. Mix the impregnated fir chips with the magnetizer, stir evenly, and dry. The dried sample was weighed and placed in a reaction furnace, protected by argon, cracked at a final temperature of 450°C, the heating rate was 5°C / min, and the magnetic activated carbon was prepared un...

Embodiment 3

[0052] Weigh 10g of zinc chloride, add 40mL of water and 2mL of concentrated hydrochloric acid to prevent hydrolysis of zinc chloride. Weigh 5g of Chinese fir sawdust, immerse the Chinese fir sawdust in zinc chloride solution for 24h, wherein the mass ratio of sawdust to zinc chloride is 1:2, weigh 0.5g Fe 3 o 4 , and 1.0g lauric acid, Fe 3 o 4 Add 15mL of water with lauric acid, add 2mL of 5mol / L NaOH solution, and bathe in water at 90°C for 0.5h; add dilute hydrochloric acid to it to pH=4~5, and collect Fe 3 o 4 The particles were washed with water until pH = 7, then 1.0g of sodium dodecylsulfonate and 20mL of water were added, and the magnetic agent was prepared in a water bath at 60°C for 1 hour. Mix the impregnated fir chips with the magnetizer, stir evenly, and dry. The dried sample was weighed and placed in a reaction furnace, protected by argon, cracked at a final temperature of 400°C, the heating rate was 5°C / min, and the magnetic activated carbon was prepared un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Total pore volume | aaaaa | aaaaa |

| Iodine adsorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap