Module combination integrated mobile crushing station

A technology of mobile crushing and module combination, applied in grain processing, etc., can solve the problems of high input cost and poor mobility of equipment, and achieve the effects of reduced transportation costs, compact structure, and flexible working space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing, the present invention will be further described:

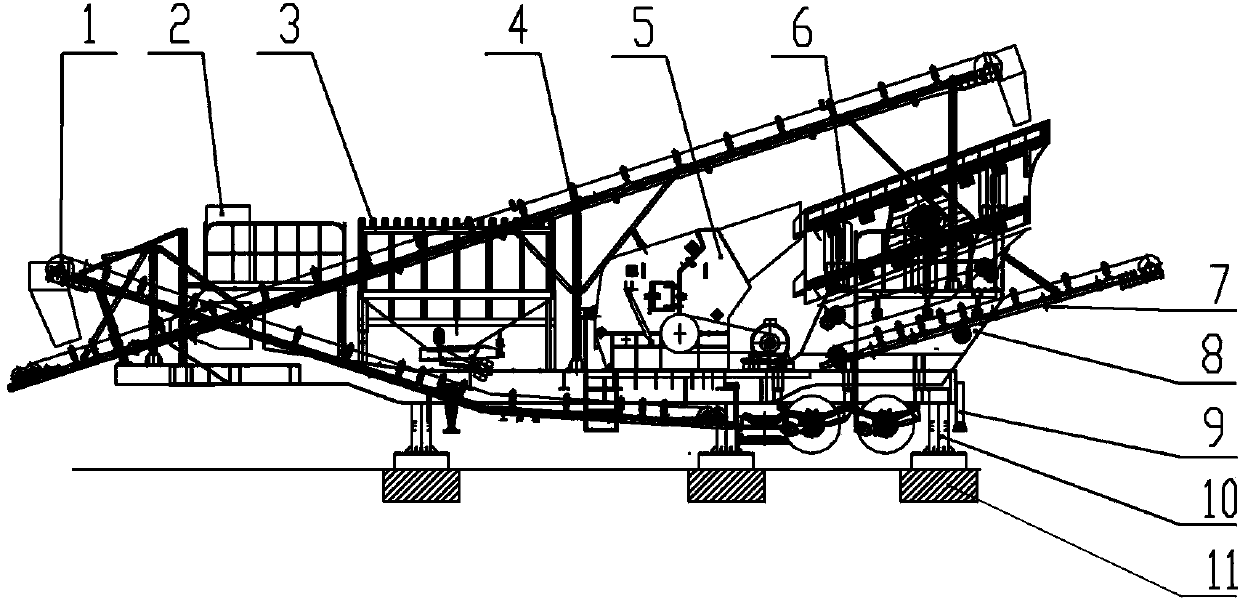

[0019] like figure 1 As shown, a modular combination integrated mobile crushing station includes a main belt conveyor 1, a control system 2, a feeding system 3, a circulating belt conveyor 4, a crushing system 5, a screening system 6, and a finished product. Reproduced belt conveyor 7, crushing station chassis system 8, chassis adjustable support legs 9, chassis fixed legs 10 and compacted foundation 11. Before moving, first use the chassis adjustable outrigger 9 to raise the chassis, and after the trailer is connected to the chassis, remove the lower part of the chassis fixed outrigger 9, and clean up the sleepers and pads under the outrigger before moving .

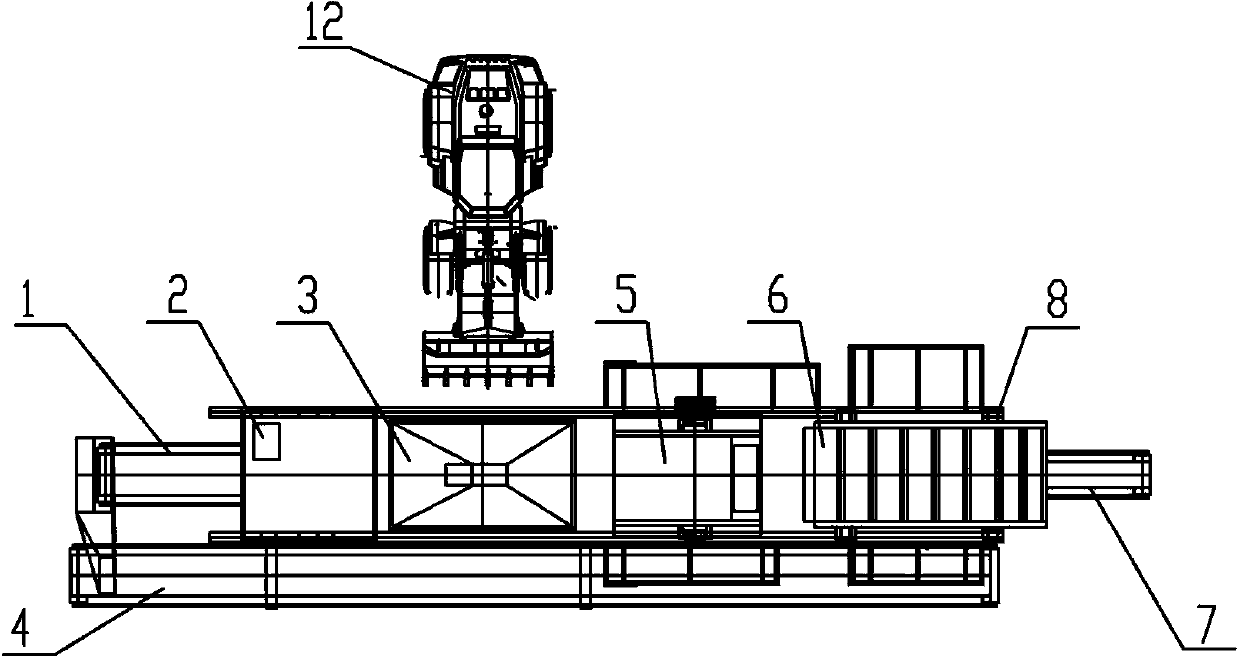

[0020] like figure 2 As shown, the material to be crushed is sent to the feeding system 3 by the forklift 12, and the material enters the main belt conveyor 1 from the feeding system 3, and is conveyed to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com