A multifunctional antifreeze spraying device and its application method

A spraying device and antifreeze technology, which is applied in the direction of spraying devices, can solve problems such as pollution, maintenance cost increase, antifreeze waste, etc., and achieve the effects of ensuring personnel safety, improving maintenance efficiency, and avoiding dead ends in spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

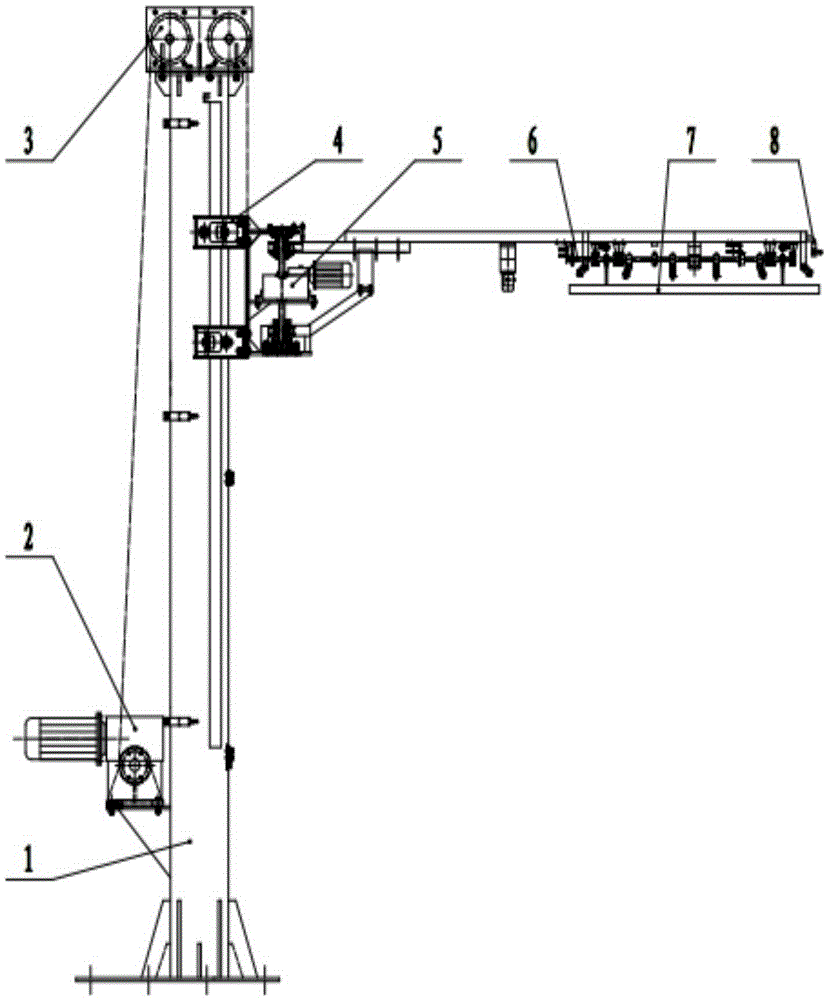

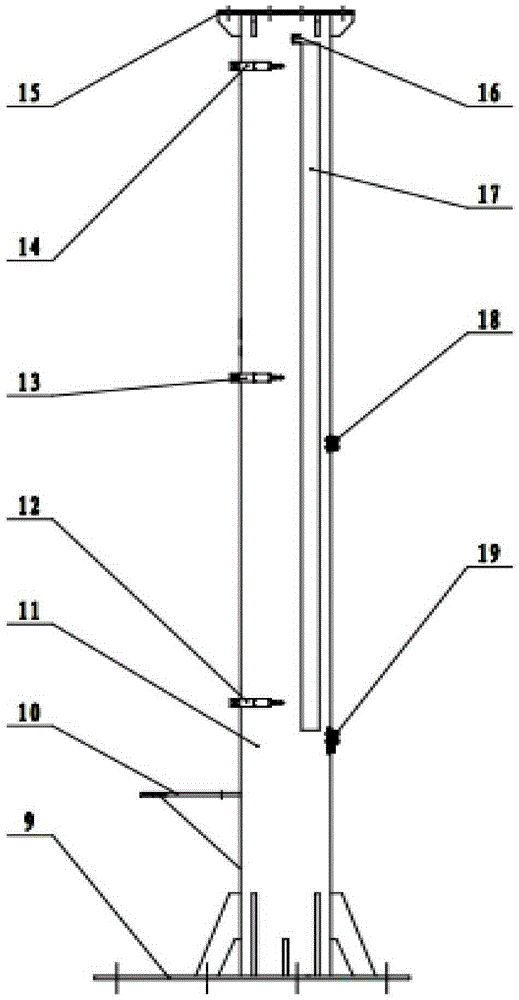

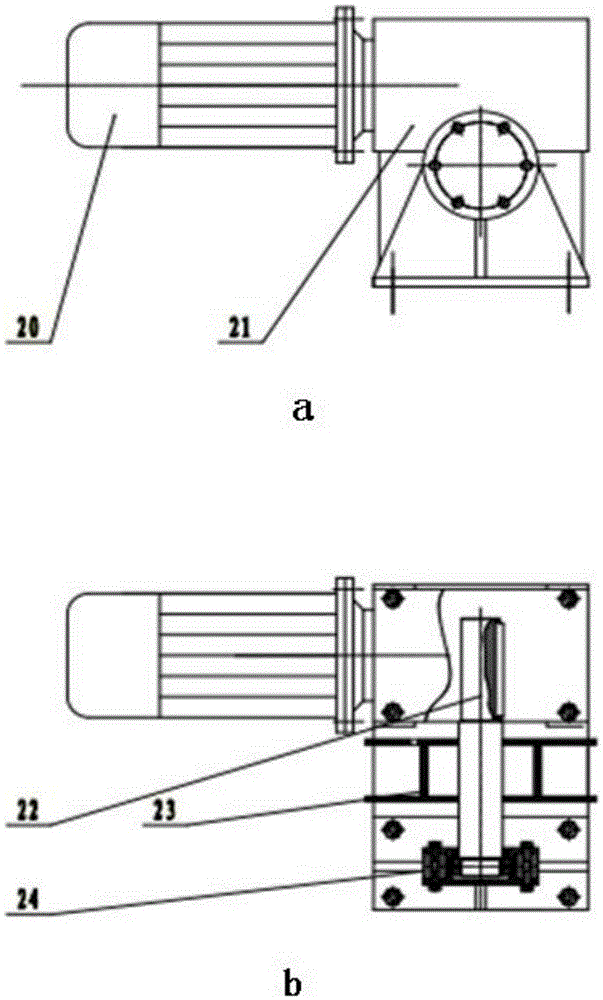

[0043] Embodiment 1 is: as figure 1 A multifunctional antifreeze spraying device is shown, which consists of a support column assembly 1, a vertical lifting drive device 2, a pulley guide mechanism 3, a vertical sliding mechanism 4, a horizontal rotation drive device 5, a spray nozzle mechanism 6, and an anti-drip mechanism 7 , pipeline system 8 and electrical control system. Such as figure 2 The supporting column 11 shown is connected with the embedded bolts of the foundation through the bottom plate 9 , and a travel switch, a limit device and a slide rail 17 are installed on the supporting column 11 . Such as image 3 a and image 3 The vertical lifting drive device shown in b is composed of a motor with brake disc 20, a worm gear reducer 21, a bearing seat 24, a reel shaft 22 and a reel 23, and the motor with brake disc 20 can quickly brake and accurately Positioning, the worm and gear reducer 21 can make the sliding equipment self-locking to ensure safety after parki...

Embodiment approach 2

[0044] Embodiment 2 is: as figure 1 As shown, the anti-drip mechanism 7 is removed, and all other mechanisms are retained, and others are the same as embodiment 1.

Embodiment approach 3

[0045] Embodiment 3 is: as figure 1 As shown, a group of nozzle groups and their connecting pipes in the spraying nozzle mechanism 6 are removed, and only one group of nozzle groups and their connecting pipes are reserved, and the others are the same as the above-mentioned embodiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com