Photoelectric PET (polyethylene terephthalate) sorting device

A photoelectric sorting and photoelectric technology, applied in the field of sorting variegated sheets, can solve problems such as lack of competitiveness of enterprises, high cost, and difficulty in controlling product quality, and achieve the effect of enhancing market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Hereinafter, a PET photoelectric separation device according to an embodiment of the present invention will be described in detail with reference to the drawings.

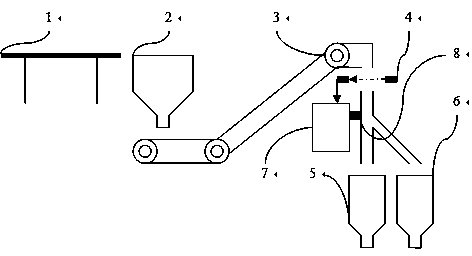

[0022] figure 1 It is a schematic diagram of a PET photoelectric separation device according to an embodiment of the present invention. Such as figure 1 As shown, it includes feeding platform 1, feeding bin 2, vibrating feeder 3, photoelectric identification head 4, PET single-color bin 5, variegated bin 6, photoelectric identification controller 7, compressed air nozzle 8 and other main equipment.

[0023] The vibration feeder 3 adjusts the fragments into a uniform state, falls along the vertical trough, and enters the compressed air nozzle 8 area through the photoelectric identification head 4;

[0024] The sensor of the photoelectric recognition head 4 automatically recognizes fragments of different colors in the PET raw material, and the recognition result is transmitted to the photoelectric recognitio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com