High-pressure hot air cleaning system for top insulator of electric locomotive

A technology for roof insulation and electric locomotives is applied in the directions of cleaning methods using gas flow, air heaters, cleaning methods and utensils, etc., which can solve the problems of difficulty in cleaning anytime and anywhere, high labor intensity, etc. The effect of labor intensity and reliability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

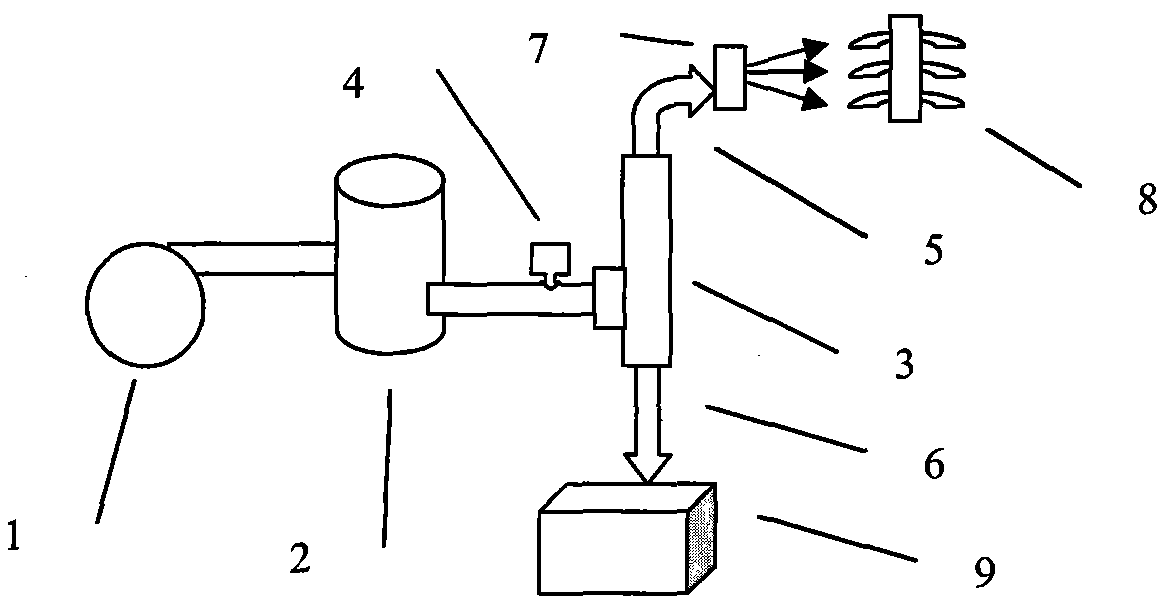

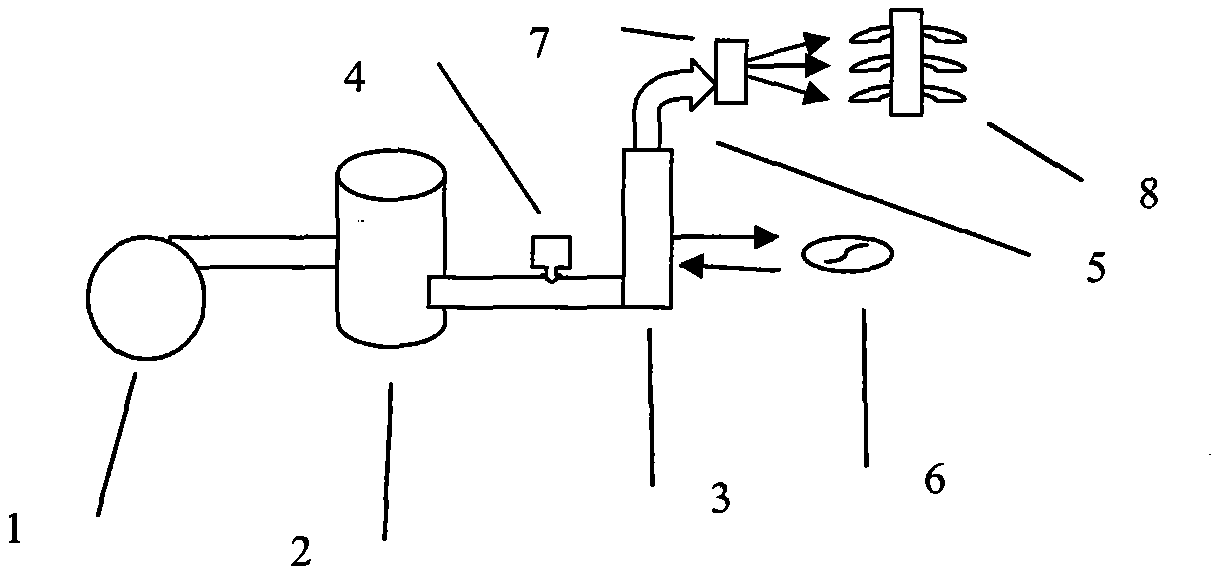

Method used

Image

Examples

Embodiment Construction

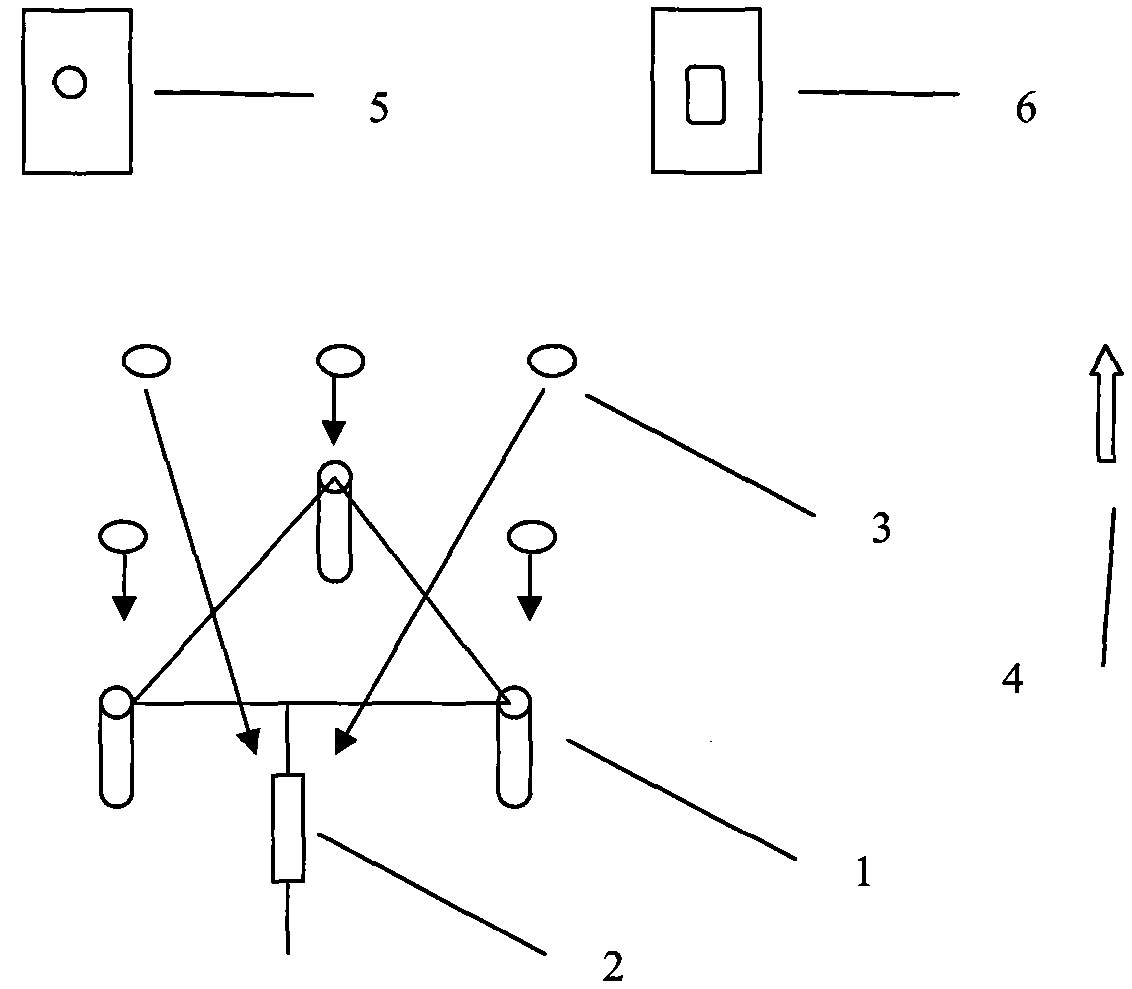

[0016] The present invention will be further described through the layout of the air nozzles.

[0017] Air nozzle and layout plan one:

[0018] Single nozzle, i.e. one jet hole per nozzle (see image 3 ). This nozzle can achieve one-way fixed-point blowing. It can be used for the downwind air nozzle layout of high-speed EMUs. Round nozzles can be designed to deliver a straight air stream, or designed to deliver a swirling air stream. Rectangular nozzles can be designed to spray straight airflow at a certain height.

[0019] Air nozzle and layout plan two:

[0020] Dual nozzles, i.e. two jet holes per nozzle (see Figure 4 ). This nozzle can realize two-way fixed-point blowing. It can be used for oblique multi-angle blowing air nozzle layout for ordinary passenger and freight electric locomotives or low-speed working conditions of high-speed EMUs.

[0021] A sufficient safety distance must be maintained between the air jets and the high-voltage components of the roof p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com