A six-degree-of-freedom industrial robot driven by a ball screw

An industrial robot, ball screw technology, applied in manipulators, manufacturing tools, program-controlled manipulators, etc., can solve the problems of large impact on robot accuracy, small working space, large cumulative error, etc., to improve dynamic performance, convenient and accurate. The effect of controlling and reducing the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

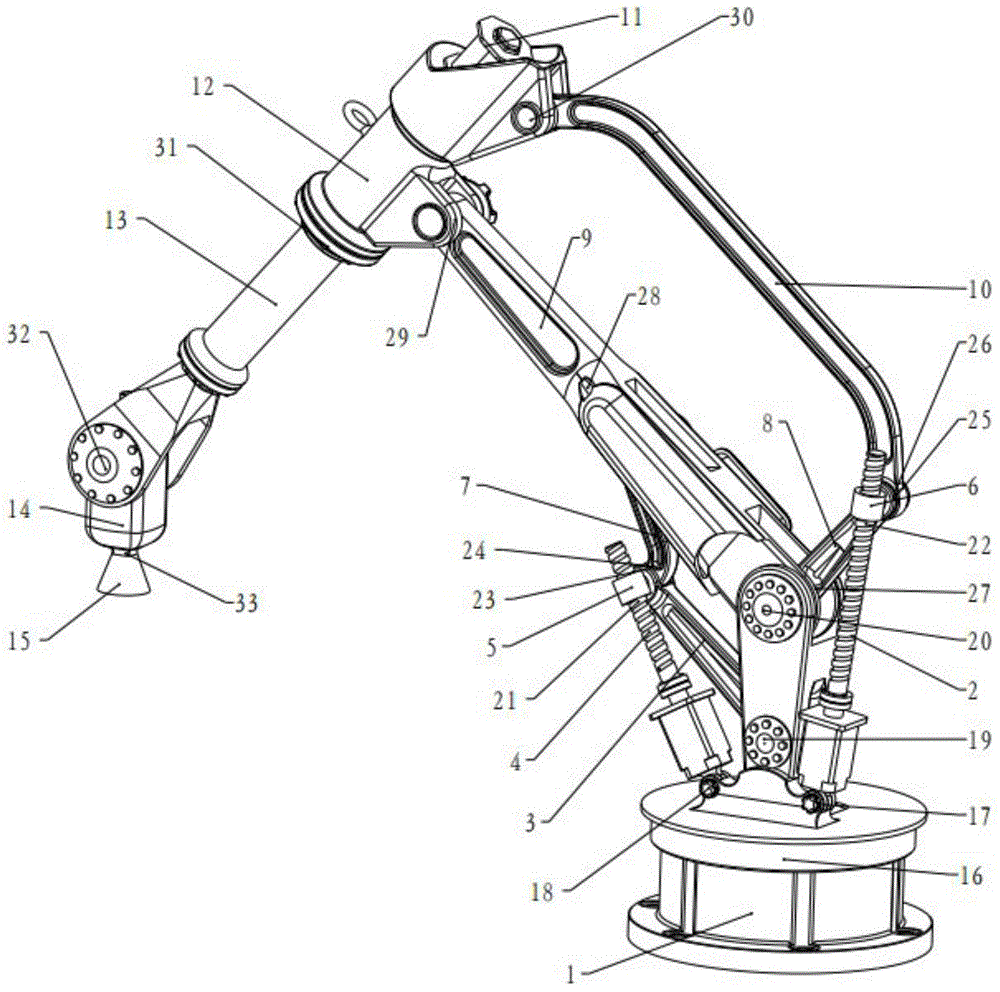

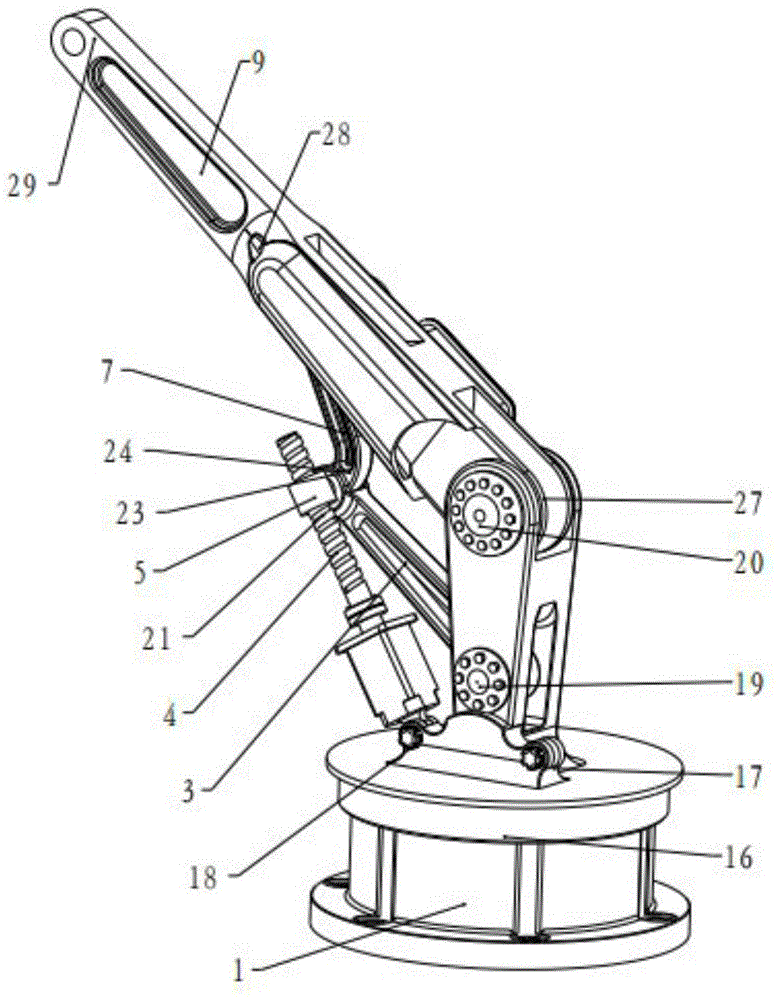

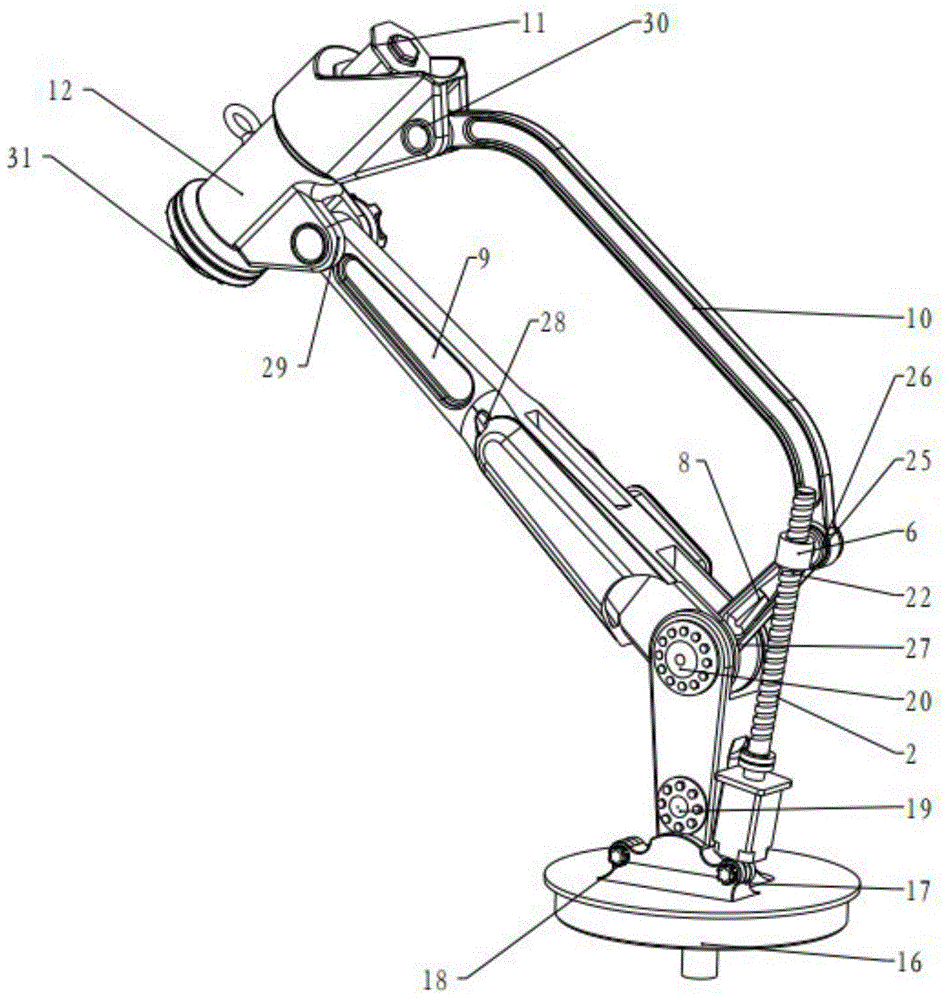

[0025] control figure 1 , 2 , 3 and 4, a six-degree-of-freedom industrial robot driven by a ball screw pair consists of a machine base, a rotary platform, a waist rotary mechanism, a shoulder swing mechanism, an elbow rotary mechanism, a forearm rotary mechanism, a wrist rotary mechanism, and a tool holder. Institutional composition. The rotary platform 16 is installed on the machine base 1 to realize the six-degree-of-freedom movement of the whole mechanism.

[0026] control figure 1 , the waist slewing mechanism is connected to the machine base 1 by the 16th revolving pair through the slewing platform 16, and is driven by the first servo motor to realize the full circle slewing motion.

[0027] control figure 1 , 2 , The shoulder swing mechanism and the elbow rotation mechanism form a position adjustment mechanism. f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com