A mold for manufacturing cylindrical mirror array

A cylindrical mirror and array technology is applied in the field of molds for manufacturing cylindrical mirror arrays, which can solve the problems of many processing links, time-consuming and laborious, and high defective rate, and achieve the effect of reducing process links, reducing costs, and improving optical performance indicators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to further explain the technical means and functions adopted by the present invention to achieve the intended purpose, the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

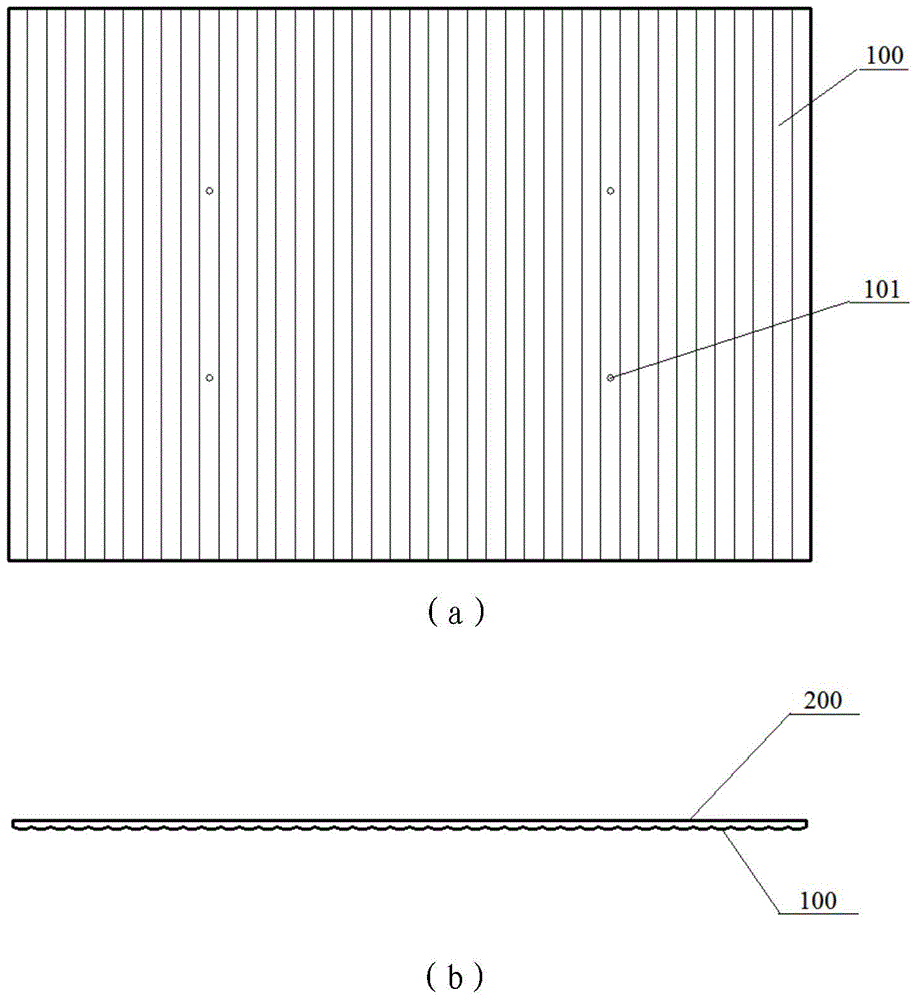

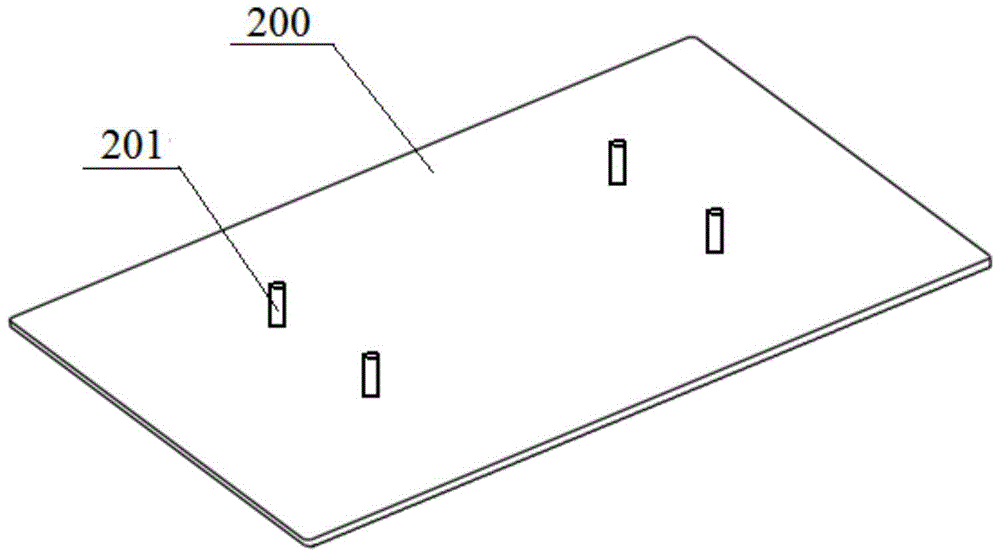

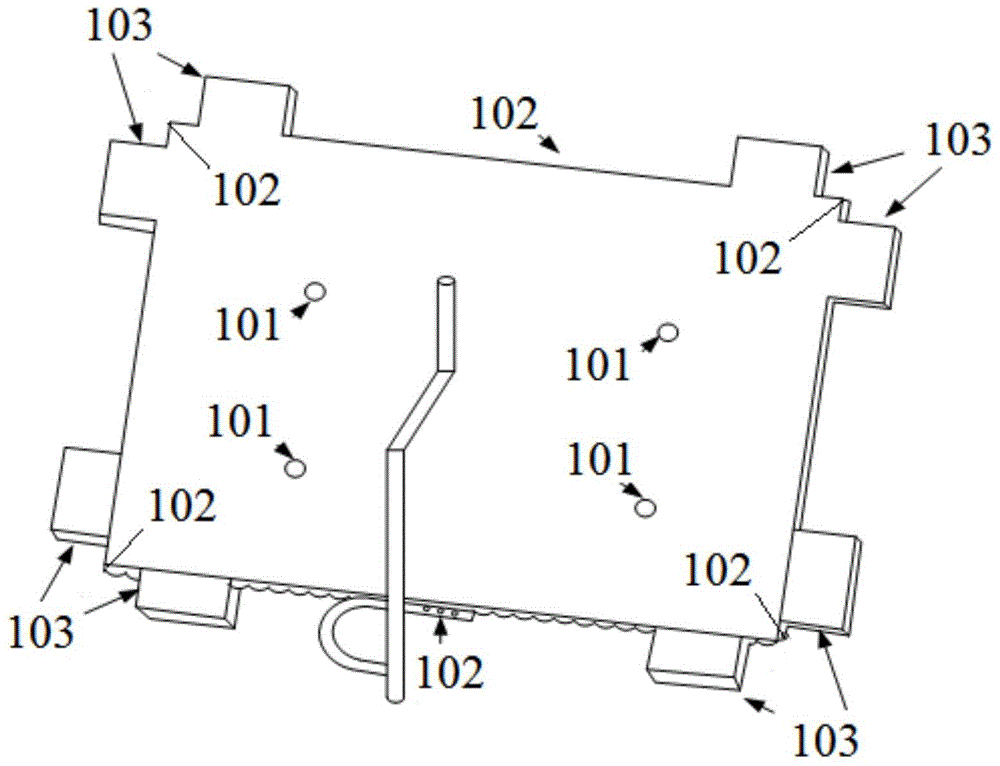

[0033] A mold for manufacturing a cylindrical mirror array according to an embodiment of the present invention, such as figure 1 As shown in (a) and (b), it includes the following components: a male mold assembly, a female mold assembly and a runner assembly, wherein the female mold assembly includes a box body 100, and the bottom surface of the box body 100 presents a cylindrical surface Mirror-shaped envelope, the male mold assembly includes a plane plate 200 as the upper cover plate of the box body, the plane plate is matched with the box body and tightly bonded at the edge. The flow channel assembly is connected to one side of the box body 100, and raw materials are injected into the box body through the flow ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com