Sliding track vehicle for dragging and launching drilling ship

A technology of drilling ships and tackles, which is applied in the directions of berth, ship, transportation and packaging, etc. It can solve the problems of equipment and process methods for launching large ships, unrecoverable underwater slideways, and uneven pressure on the bladder wall, etc., so as to achieve short construction time , cost reduction, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

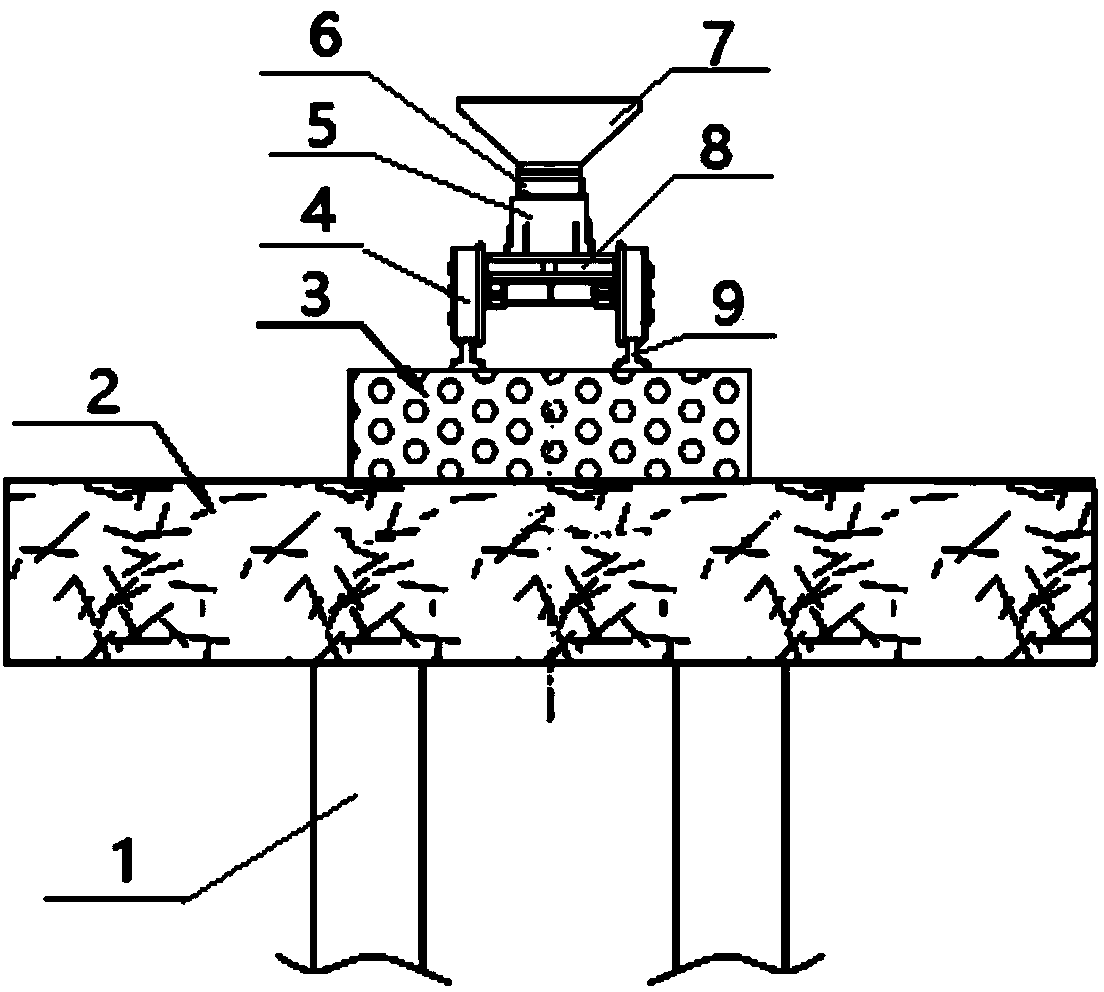

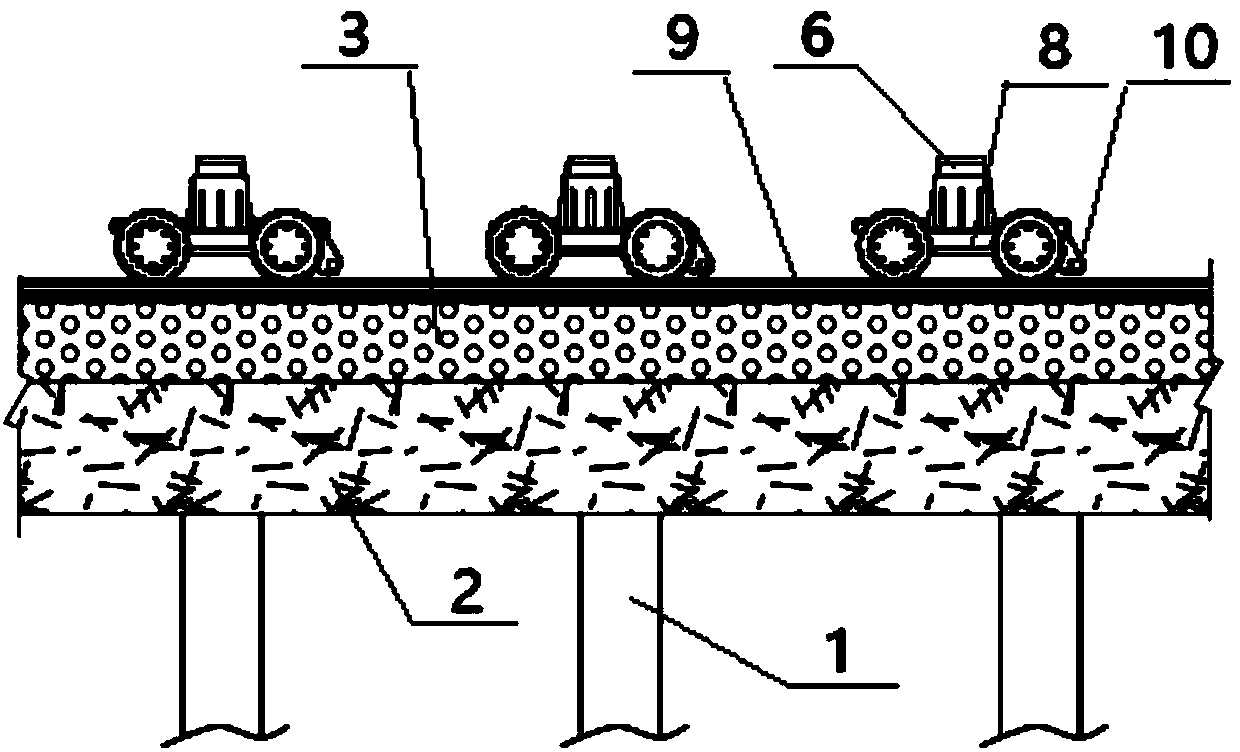

[0018] Embodiment 1: as attached figure 1 As shown, the roller 4 is installed at the bottom of the tackle 8, and the hydraulic cylinder 5 is installed vertically on the top of the tackle 8, and the piston 6 is installed on the hydraulic cylinder 5.

[0019] Among the foregoing, a pair of rollers 4 are respectively installed front and rear at the bottom of the tackle 8 .

[0020] Among the foregoing, a roller 4 is respectively installed front and back at the bottom of the tackle 8 .

[0021] In the foregoing, the top end of the piston 6 on the pulley 8 is installed with the socket 7 .

[0022] In the foregoing, the traction device 10 is installed on the tackle 8 .

[0023] Among the foregoing, foundation pile 1 is built at the bottom of wharf 2, fixed rail seat 3 on the top of wharf 2, track 9 is laid along rail seat 3, and tackle 8 is placed on track 9 top with roller 4.

[0024] In the foregoing, the seat 7 is in the shape of a truncated cone, with a height of 400mm and a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com