Composite fiber material used in mixed asphalt material

A technology of asphalt mixture and composite fiber, which is applied in the field of pavement asphalt materials, can solve the problems of limited improvement of asphalt mixture road performance, single improvement of asphalt mixture road performance, etc., and achieves radiation and ultraviolet chemical resistance Stability, good chemical stability, strong physical adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

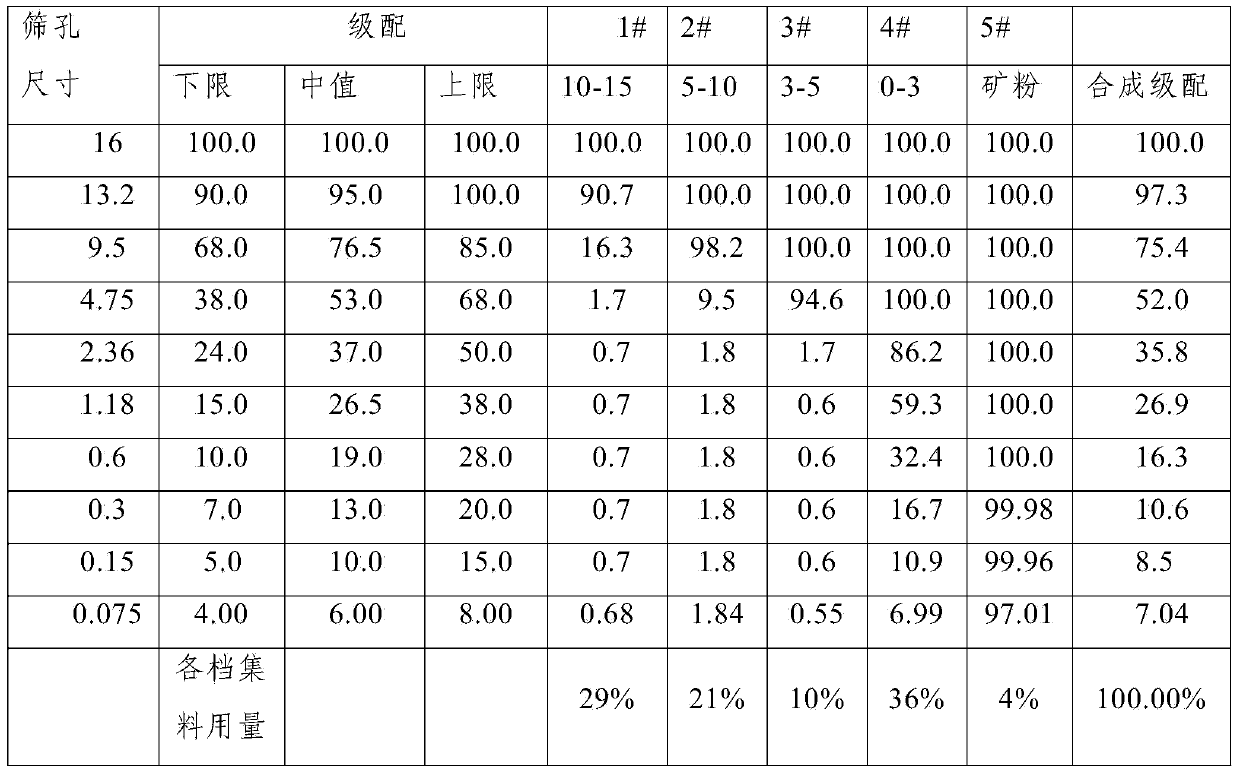

[0015] The composite fiber material for the asphalt mixture of this embodiment is made by mixing and mixing the following raw materials in weight percentages: 50% lignin fiber, 33% basalt fiber, and 17% sepiolite fiber. When the composite fiber material of this embodiment is used to prepare the modified asphalt mixture, the amount of the composite fiber material is 3‰ of the weight of the asphalt mixture.

Embodiment 2

[0017] The composite fiber material for the asphalt mixture in this embodiment is made by mixing and mixing the following raw materials in weight percentages: 48% lignin fiber, 34% basalt fiber, and 18% sepiolite fiber. When the composite fiber material of this embodiment is used to prepare the modified asphalt mixture, the amount of the composite fiber material is 3‰ of the weight of the asphalt mixture.

Embodiment 3

[0019] The composite fiber material for asphalt mixture in this embodiment is made by mixing and mixing the following raw materials in weight percentages: 52% lignin fiber, 32% basalt fiber, and 16% sepiolite fiber. When the composite fiber material of this embodiment is used to prepare the modified asphalt mixture, the amount of the composite fiber material is 3‰ of the weight of the asphalt mixture.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com