Pressure quenching method of high-hardness 5Cr13MoV wearable liner

A wear-resistant lining plate and wear-resistant plate technology, applied in heat treatment equipment, furnaces, heat treatment furnaces, etc., can solve problems such as low service life and poor wear resistance, reduce deformation and cracking, and reduce quenching thermal stress and structure. Stress, the effect of increasing hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0018] Take the 5Cr13MoV and Q235 composite wear-resistant plate with a specification of 1000mm long × 1000mm wide × 45mm thick as an example:

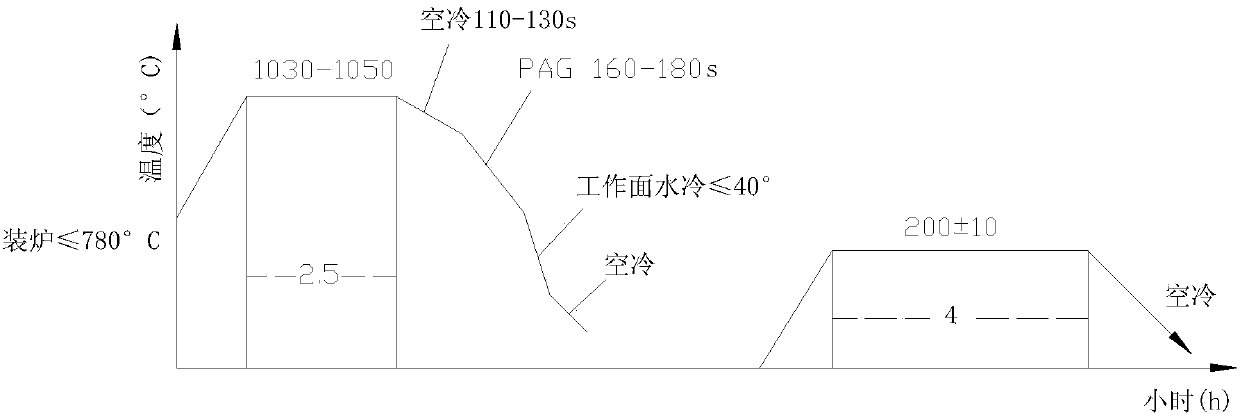

[0019] Quenching is heated in a push rod heating furnace, the temperature of the workpiece entering the furnace is ≤870°C, the temperature is raised to 1030-1050°C and kept for 2.5h, and the furnace is cooled in the air for 110-130S, then enters the quenching press, and is covered with 5 meshes of 100×100×5mm Grid gasket, after pressing, immerse in 0.3% PAG (20-23°C) coolant, cool for 160-180S, take it out from the press, spray water on the convex surface to cool down to the wear-resistant plate surface temperature ≤ 40°C, and then put it in the air Let cool to room temperature.

[0020] Tempering is carried out in a trolley-type resistance furnace, heated to 200±10°C for 4 hours, and then air-cooled. After quenching treatment, the quenching hardness of the working face is ≥HRC56, the depth of the hardened layer is ≥5mm, the flatness...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com