Automatic tin adding mechanism

An automatic, tin bar technology, applied in coating, metal material coating process, hot-dip plating process, etc., can solve the problems of local temperature drop of tin furnace, uneven thickness of tin plating layer, unstable liquid level of tin furnace, etc. , to achieve the effect of reducing rework rate, improving qualification rate and reducing manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preferred embodiments of the present invention are described in detail below, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

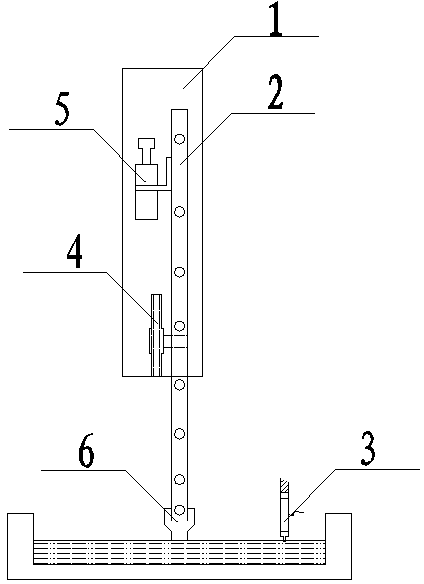

[0016] The present invention is an automatic tinning mechanism, see figure 1 As shown, it is used for tinning of photovoltaic ribbon, a fixed bracket 1, a tin bar storage device 2, a temperature sensing device 3, a lifting slot 4 and a control adjustment device 5, the fixed bracket 1 is arranged above the tin furnace, and the tin bar The storage device 2, the lift tank 4 and the control and adjustment device 5 are arranged inside the fixed bracket 1, the control and adjustment device 5 is arranged on the back of the tin bar storage device 2, and the temperature sensing device 3 is arranged on the tin liquid in the tin furnace.

[0017] A tin bar retaining groove 6 is provided at the tail of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com